Electromagnetic heating electric cooker and cooking method thereof

A cooking method and technology of an electric rice cooker are applied to the utensils with an integral electric heating device, the structure of the cooking utensils, the heating device, etc., and can solve the problems of reduced IGBT service life, large IGBT inrush current, and poor rice taste, etc. The effect of reducing intermittent time, reducing working noise, and improving the taste of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

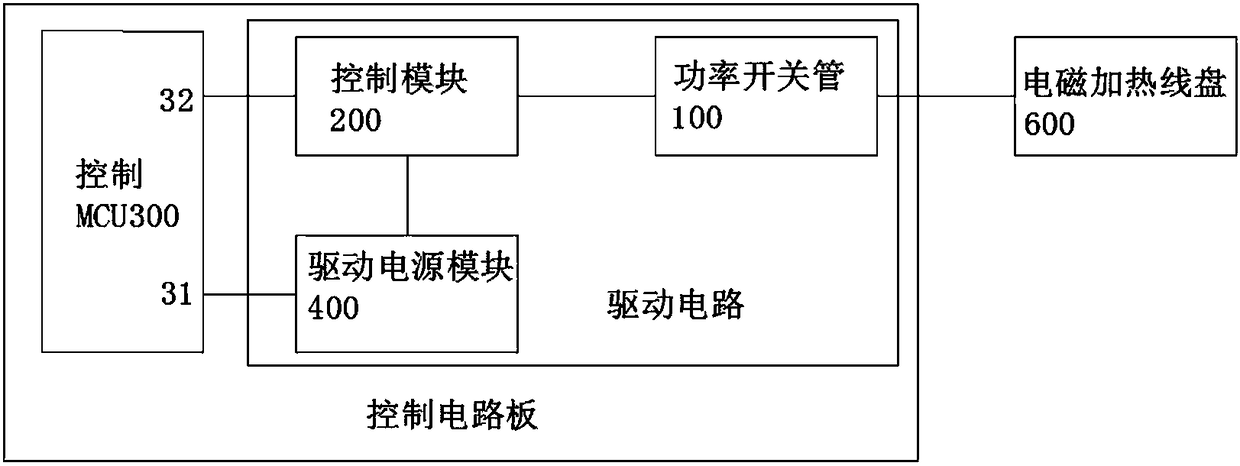

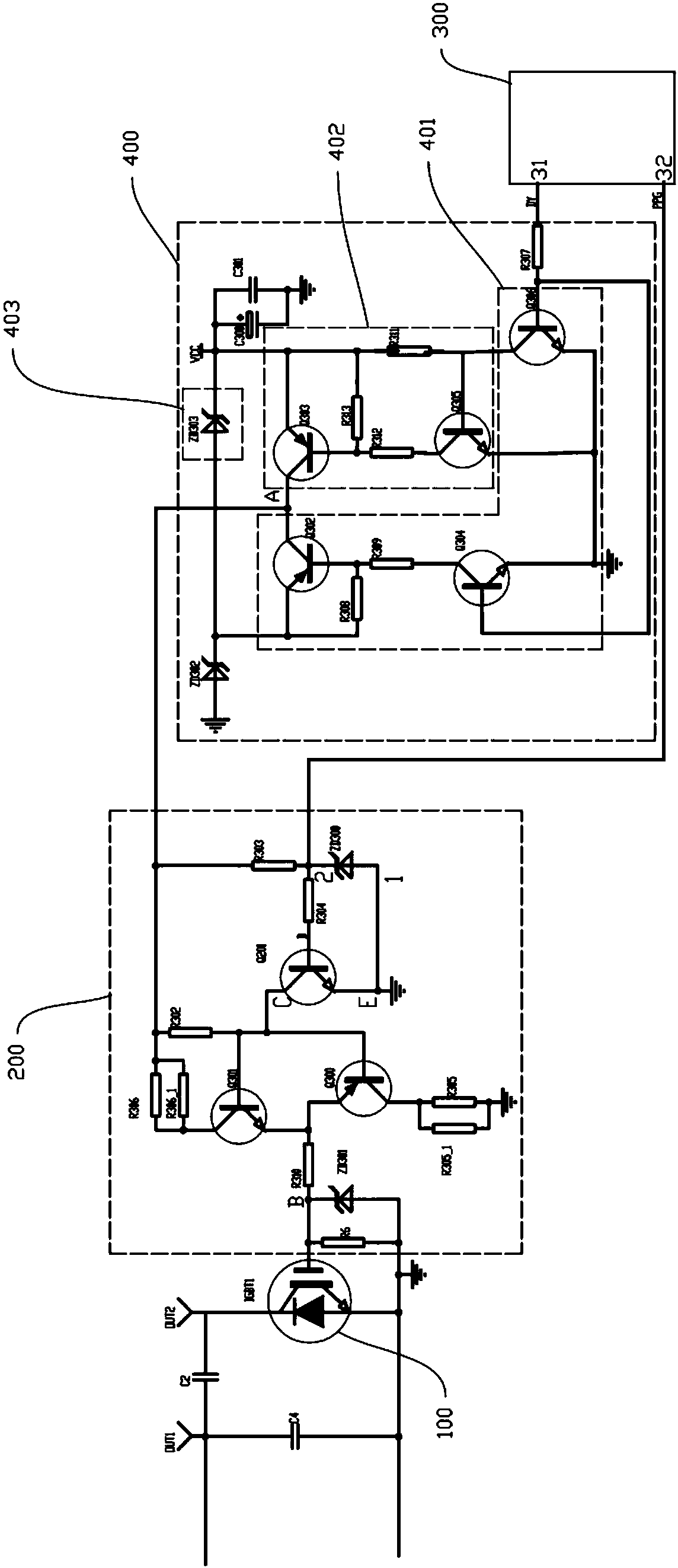

[0035] See Figure 1 to Figure 3, the present invention provides an electromagnetic heating electric rice cooker, comprising a control circuit board, an electromagnetic heating coil 600 and an inner container, the control circuit board comprising a drive circuit connected to the electromagnetic heating coil 600 and a control MCU 300, the drive circuit comprising a drive The power supply module 400, the control module 200 and the power switch tube 100, the control MCU 300 includes a first output port 31 connected to the drive power supply module 400, and a second output port 32 connected to the control module 200, and the output end of the drive power supply module 400 is connected to the control module 200, the output end of the control module 200 is connected to the power switch tube 100, the first output port 31 of the control MCU 300 outputs different control signals, so that the driving power module 400 generates at least two kinds of driving voltages, and the second output...

Embodiment 2

[0044] This embodiment provides a cooking method for an electromagnetic heating electric rice cooker, and the cooking method includes a high-power cooking stage, a low-power cooking stage, and a high-power switching stage.

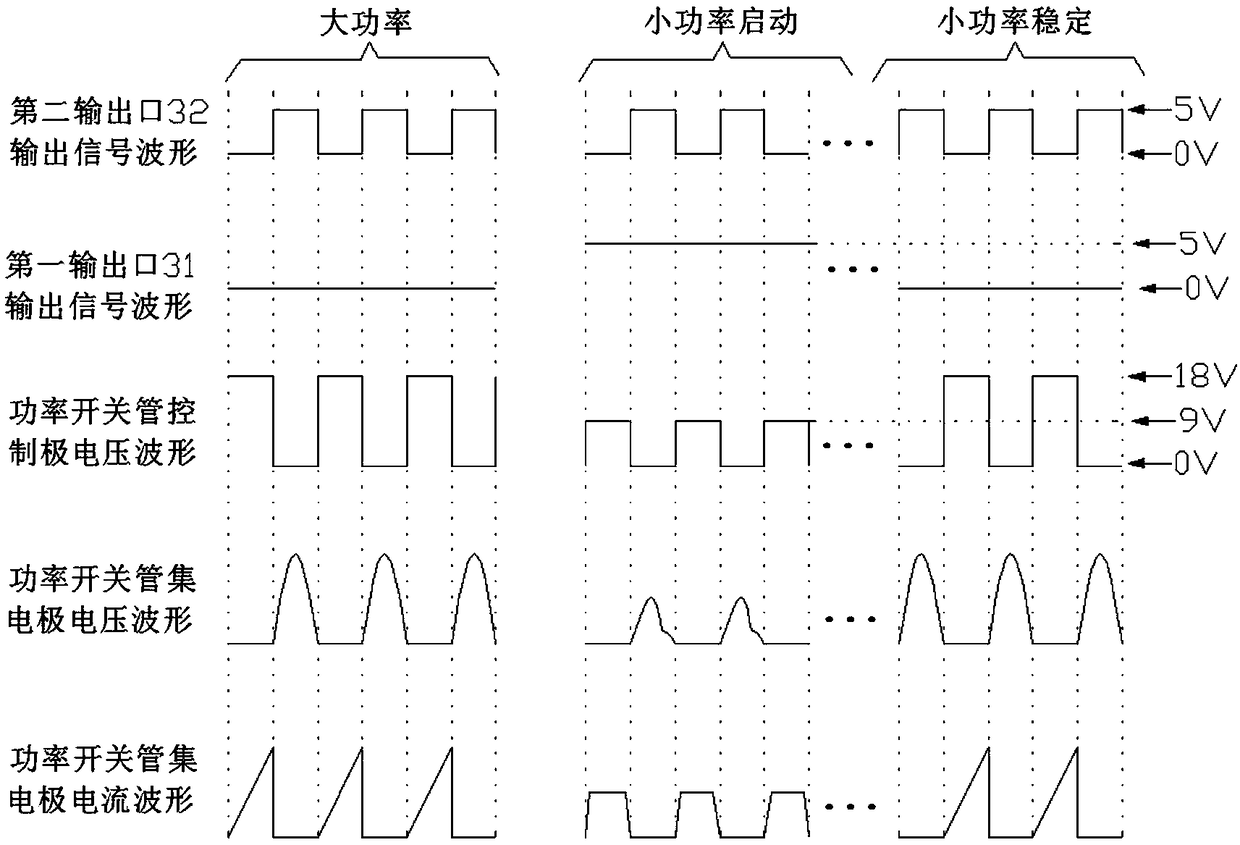

[0045] see Figure 5 shown in the voltage envelope diagram, combined with image 3 understand. Wherein, the control method of the high-power cooking stage is as follows: control the first output port 31 of the MCU 300 to output the first control signal, drive the power supply module 400 to generate the second driving voltage, and control the second output port 32 of the MCU 300 to output different control signals. signal, so that the control module 200 drives the power switch tube 100 to switch between the saturated conduction state or the cut-off state, so that the continuous output of power is above 800 watts;

[0046] The control method of the low-power cooking stage is as follows: the first output port 31 of the control MCU 300 outputs the second con...

Embodiment 3

[0057] see Figure 6 , which is a flow chart of another embodiment of the cooking method of the electromagnetic heating electric rice cooker of the present invention, and its main difference from Embodiment 2 is that the cooking method further includes an aroma-increasing stage S31. Specifically, there is an aroma-increasing stage between steps S3 and S4 in the second embodiment, a low-power cooking stage is used, and the temperature is maintained at 92-95° C. for at least 1 minute. The low-power cooking stage can keep the temperature at 92-95°C. If it lasts for more than 1 minute in this temperature range, it can decompose the esters in the rice, greatly increase the aroma of the rice, and improve the quality of the rice. taste. Preferably, the maintaining temperature is 93° C., and the duration is 1-6 minutes. In this temperature point and time range, the aroma enhancement effect is the best.

[0058] see Figure 7 In the stage of water absorption, the temperature at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com