Ignition plug and ignition system provided with same

A technology of spark plugs and ground electrodes, which is applied in the field of ignition systems, can solve the problems of low input energy, and achieve the effects of less flame retardant effect, suppression of flame retardant effect, and promotion of combustibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

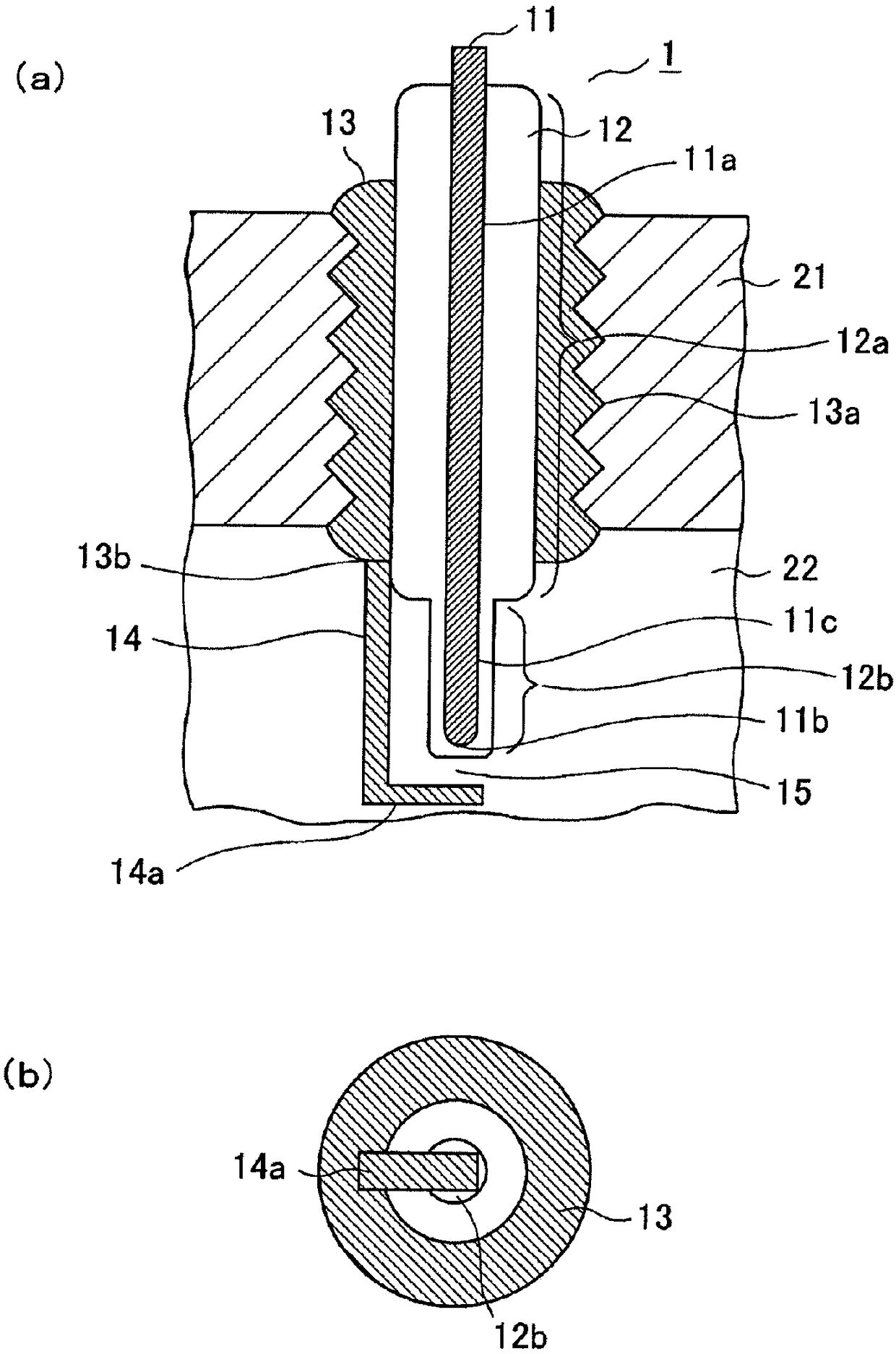

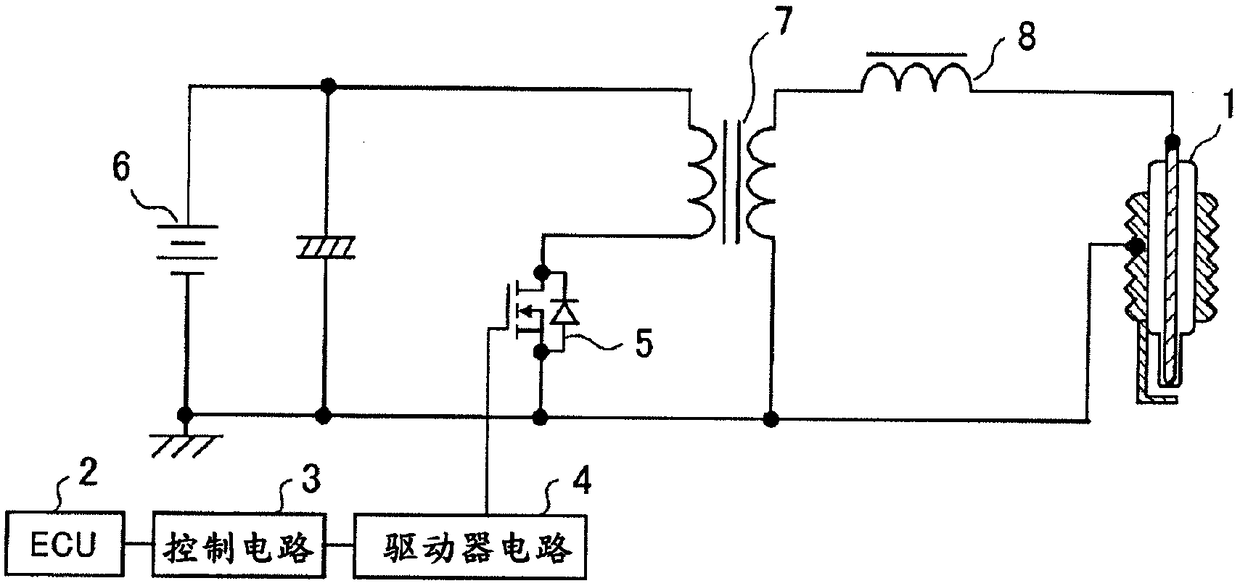

[0057] Hereinafter, the spark plug according to Embodiment 1 of the present invention and an ignition system provided with the spark plug will be described based on the drawings. figure 1 It is a cross-sectional view and a bottom view showing the spark plug of the first embodiment. Such as figure 1 As shown, the spark plug 1 of the first embodiment includes a rod-shaped high-voltage electrode 11, a first dielectric 12a covering a peripheral surface 11a of the high-voltage electrode 11, a cylindrical main body metal member 13, and a rod-shaped ground electrode 14.

[0058] The main body metal fitting 13 as the frame body of the spark plug 1 has a threaded portion 13a on its peripheral surface and is fixed to the inside of the partition wall 21 facing the combustion chamber 22 of the engine. The rod-shaped ground electrode 14 is connected to one end surface 13 b of the main body metal fitting 13. The main metal fitting 13 and the ground electrode 14 have the same ground potential a...

Embodiment approach 2

[0070] In the second embodiment of the present invention, use Figure 5 ~ Figure 7 , The spark plug 1 ( figure 1 ) Basic modification. In addition, in each figure, the same code|symbol is attached|subjected to the same or equivalent part in the figure, and description is abbreviate|omitted.

[0071] In order to generate a barrier discharge, a second dielectric 12b needs to be interposed between the high-voltage electrode 11 and the ground electrode 14. The second dielectric 12b may be any electrode. In the first embodiment described above, the high-voltage electrode 11 is covered with the second dielectric 12b, but it may be as Figure 5 As shown, the ground electrode 14 is covered by the second dielectric 12b to form a dielectric electrode. In this case, the end 11c of the high-voltage electrode 11 is exposed from the dielectric 12.

[0072] In addition, in Embodiment 1 described above, an example in which one rod-shaped ground electrode 14 is arranged is shown, but there may be ...

Embodiment approach 3

[0083] In the third embodiment of the present invention, the spark plug 1 ( figure 1 ) A modification of using Figure 8 ~ Figure 18 A description will be given of an example in which a protrusion or a small metal piece having a tip is provided on the surface of the high-voltage electrode 11, the second dielectric 12b, or the ground electrode 14 facing the discharge region 15. In addition, in each figure, the same reference numerals are attached to the same and corresponding parts in the figures, and the description is omitted.

[0084] in Figure 8 In the example shown, the ground electrode 14 is a metal electrode, and a first protrusion 16 is provided at a portion of the bent portion 14a facing the discharge area 15 and the first protrusion 16 has a tip that protrudes toward the discharge area 15. unit. In addition, in Picture 9 In the illustrated example, the ground electrode 14 is four thin rod-shaped metal electrodes, and the first protrusion 16 is provided at the tip porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com