Winding grid fiber composite wire

A fiber composite and winding technology, applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of lead-acid batteries containing lead and serious environmental pollution, and achieve the effects of reducing weight, ensuring full contact, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

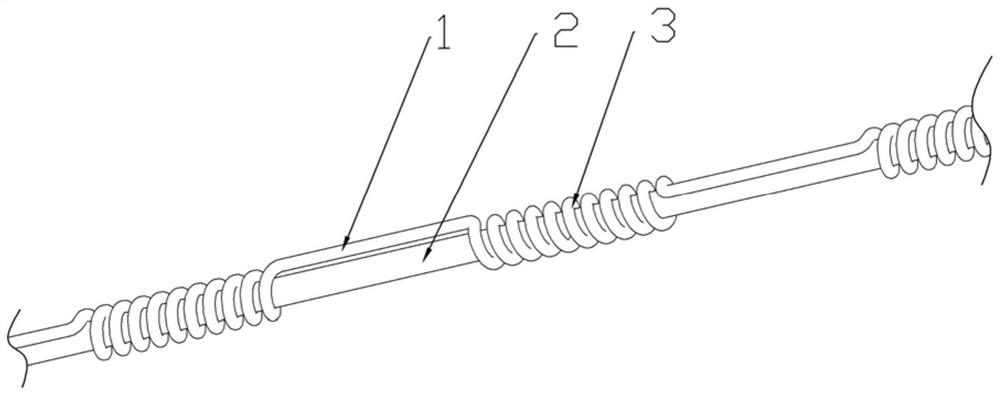

[0013] Embodiment: the winding type grid fiber composite wire in this scheme, such as figure 1 As shown, it includes synthetic wires and copper wires 2. The components of the synthetic wires include lead-free glass and porous carbon;

[0014] The compound wire manufacturing method in this scheme comprises the following steps:

[0015] Step 1: Preparation of lead-free glass powder

[0016] The formula composition of lead-free glass powder: proportioning by mass fraction, B 2 o 3 2%, Bi 2 o 3 3%, ZnO 3%, Al 2 o 3 is 2%, MgO is 2.5%, BaO is 7.5%, and the balance is SiO 2 .

[0017] Add the above ingredients into the ceramic crucible in batches, and when the temperature of the box-type sintering furnace rises to 1250°C, put the ceramic crucible into the sintering furnace. Mill in a ball mill jar for 72 hours, and sieve through a 400-mesh sieve to obtain glass powder with an average particle size of 3 μm, and obtain lead-free glass powder with a softening point of 800°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com