Waterproof and moisture permeable cloth with three-dimensional structure, production method and wall structure

A waterproof and moisture-permeable, three-dimensional structure technology, applied in chemical instruments and methods, building components, layered products, etc., can solve the problems of high labor cost and material cost, troublesome construction, etc., achieve good waterproof and moisture-permeable effect, and ensure construction. quality, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

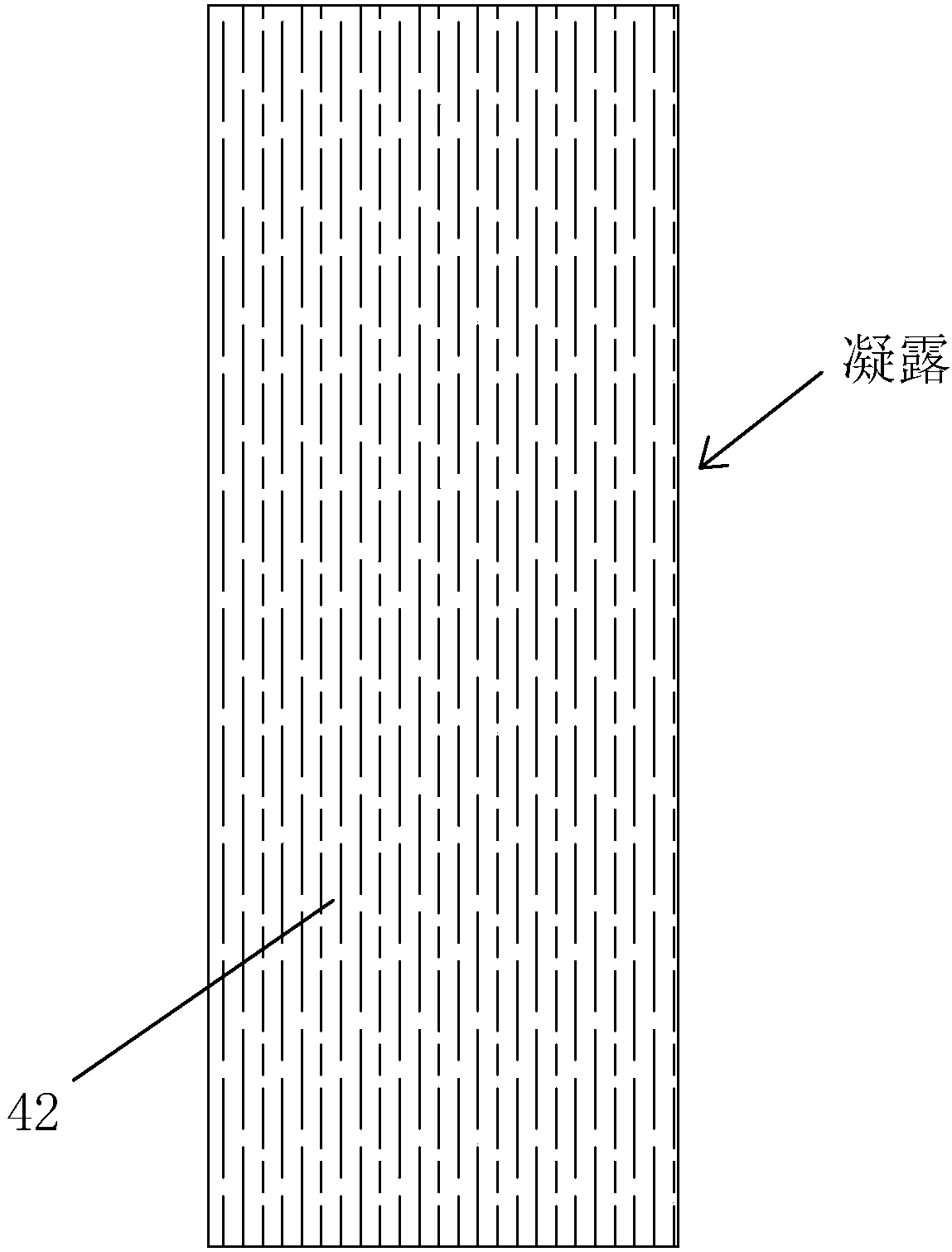

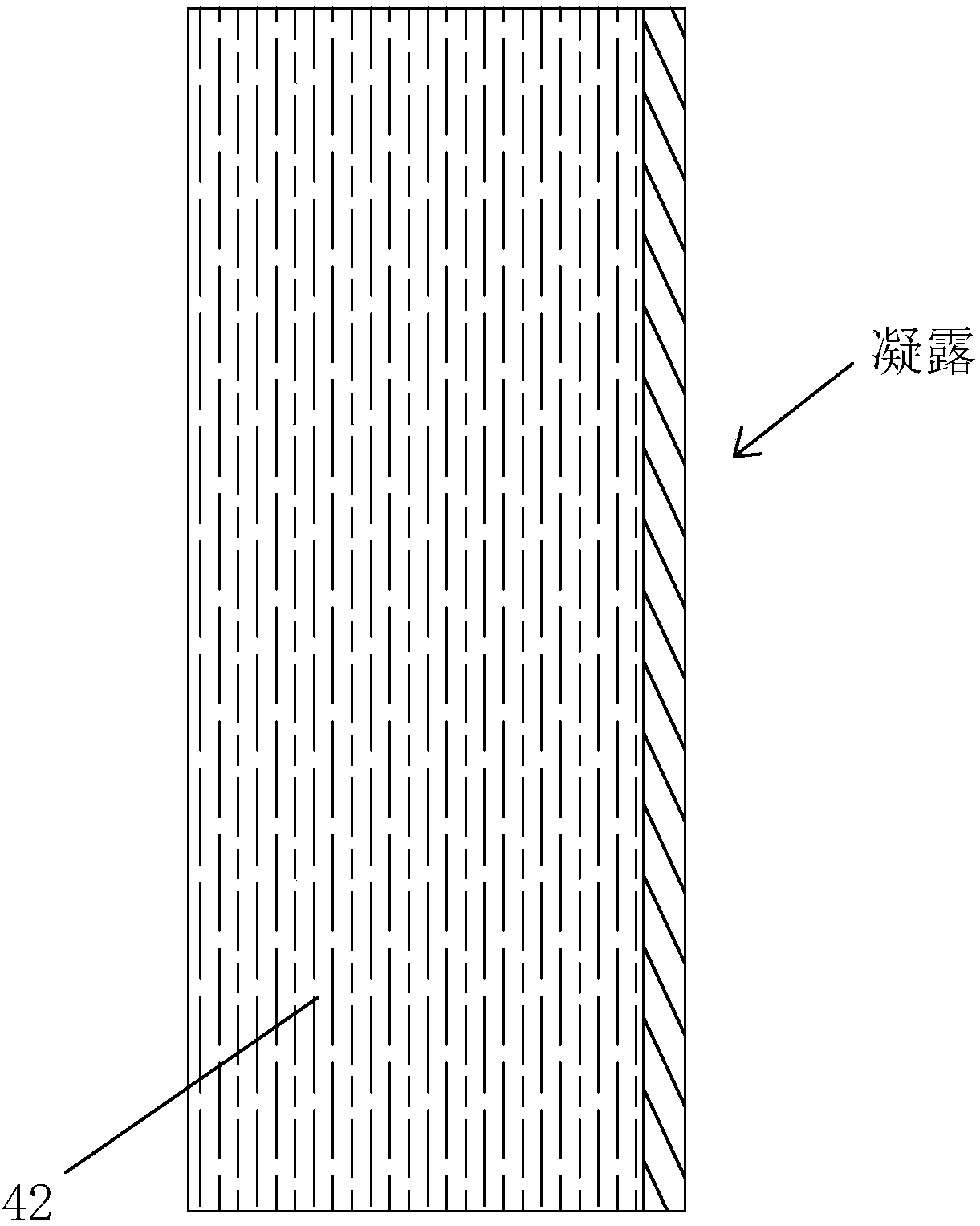

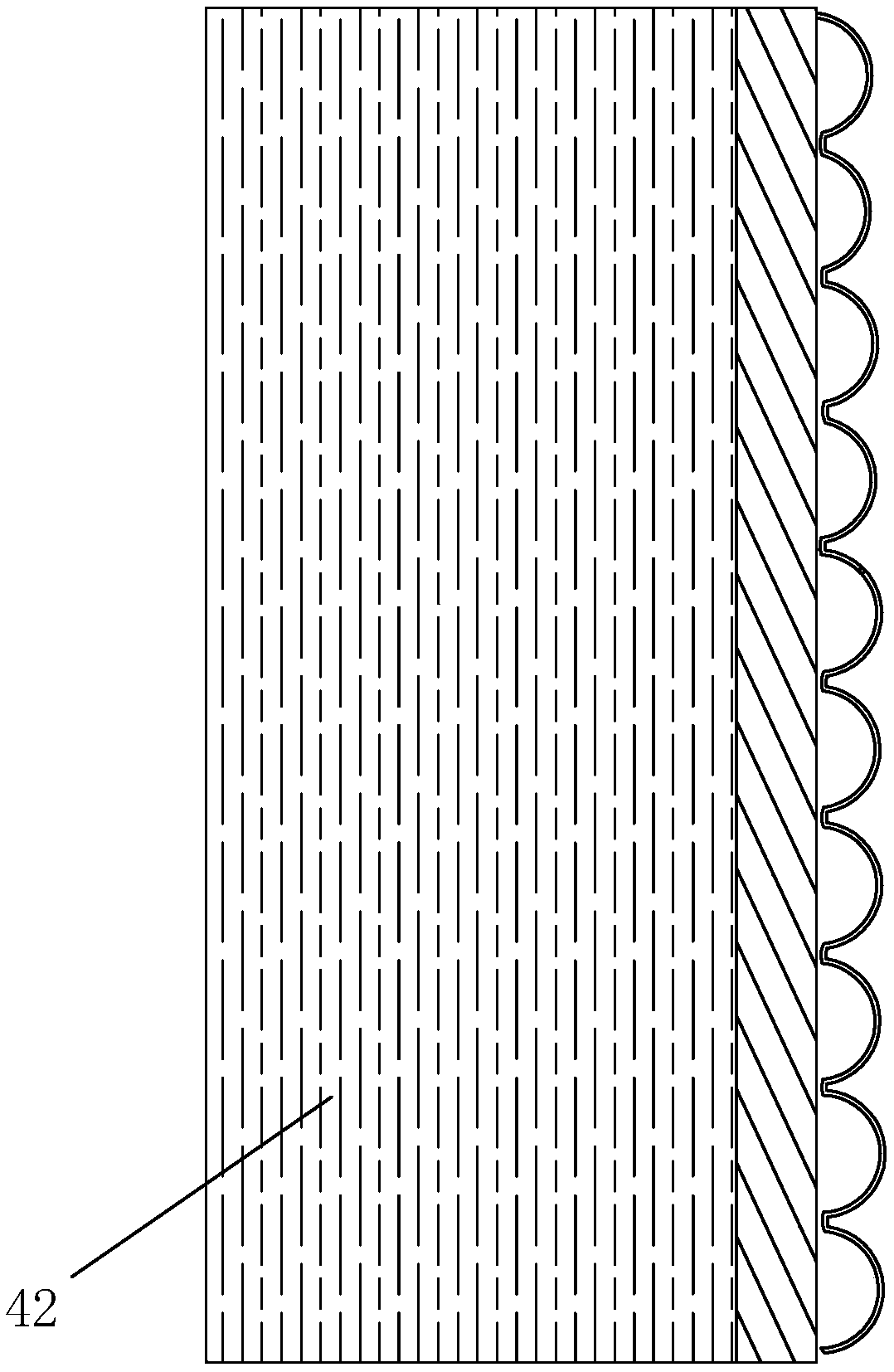

[0071] A waterproof and moisture-permeable cloth with a three-dimensional structure, such as Figure 4 As shown, it includes a waterproof and moisture-permeable cloth 1 and a gap layer 2 (forming an air duct in the waterproof and moisture-permeable wall structure) from top to bottom, wherein the waterproof and moisture-permeable fabric 1 includes three layers: the first non-woven fabric layer 11, the waterproof and moisture-permeable The wet function layer 12, the second non-woven fabric layer 13; the thickness ratio of the first non-woven fabric layer 11, the waterproof and moisture-permeable functional layer 12 and the second non-woven fabric layer 13 is 5:2:3, and the waterproof and moisture-permeable functional layer 12 can be made of materials such as PE or TPU, such as Image 6 As shown, the gap layer 2 is made of several elastic protrusions 21, and the structure of the elastic protrusions 21 is as follows: Figure 5 As shown, the elastic protrusions 21 are made of plas...

Embodiment 2

[0074] A method for producing a waterproof and moisture-permeable cloth with a three-dimensional structure, mainly comprising the following steps:

[0075] Stp1: fix the waterproof and moisture-permeable cloth 1, and the surface is smooth;

[0076] Stp2: heating the elastic protrusion 21 until it becomes viscous. In this embodiment, heating is adopted, and the heating method can be blanching, thermal radiation heating or sonic heating;

[0077] Stp3: stick the elastic projections 21 processed in Stp2 on the surface of the first waterproof fabric layer 1 to form a complete waterproof and moisture-permeable fabric with a three-dimensional structure.

[0078] The waterproof and moisture-permeable fabric with three-dimensional structure prepared here is the waterproof and moisture-permeable fabric shown in Example 1.

Embodiment 3

[0080] A method for producing a waterproof and moisture-permeable cloth with a three-dimensional structure, mainly comprising the following steps:

[0081] Stp1: fix the waterproof and moisture-permeable cloth 1, and the surface is smooth;

[0082] Stp2: Fix the elastic protrusions 21 on the surface of the first non-woven fabric layer 11 by laser welding to form a complete waterproof and moisture-permeable fabric with a three-dimensional structure.

[0083] The waterproof and moisture-permeable fabric with a three-dimensional structure prepared here is the waterproof and moisture-permeable fabric with a three-dimensional structure shown in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com