Waterproof and moisture-permeable film and preparation and application thereof

A moisture-permeable film and composite film technology, applied in textiles and papermaking, chemical instruments and methods, lamination, etc., can solve problems such as poor film strength and low production efficiency, and achieve poor strength, improve strength, and solve low productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

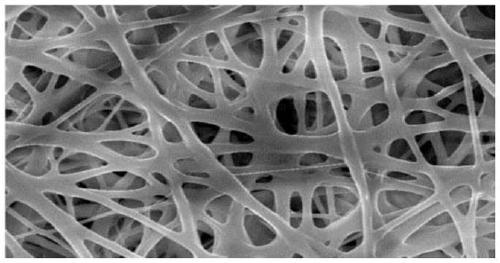

[0038] The preparation method of electrospun 15μ thick microporous mesoporous membrane: 15μ refers to the thickness, and the pore diameter is about 150 nanometers.

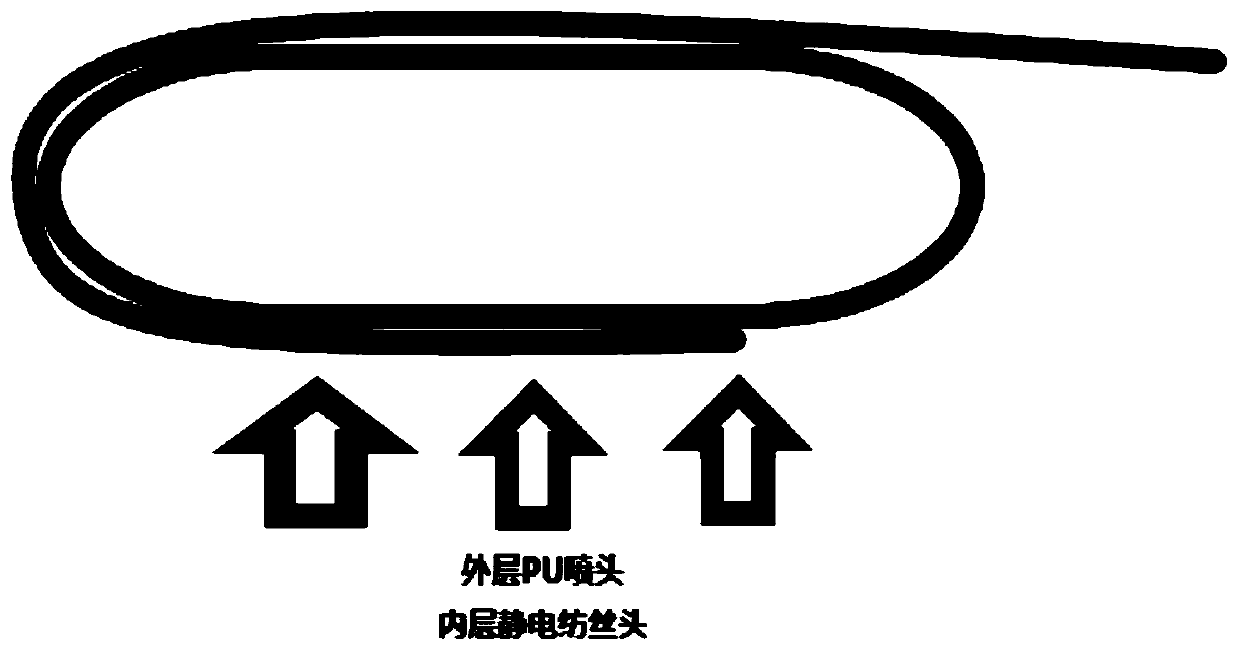

[0039] Production process: (PU spraying + electrospinning) - heating and curing film formation - fabric hot-melt lamination - washing and drying - finished product.

[0040] Among them, the PU spraying + electrospinning spinning process is carried out by three spraying and three spinning methods. The feeding ratio of the three-stage process is: the first stage is 32.5% PU + 0.5% PEO, the second stage is 33.5% PU + 0.5% PEO , the third paragraph 32% PU + 1% PEO. (mass percentage)

[0041] Specific parameters: PEO electrospinning spinning process, the first static voltage is 50KV, the second static voltage is 50KV, the third static voltage is 75KV, and the spinning height is 25cm; PU spraying process, the spray height is 30cm, and the spray particle size is 30-80 Micron.

[0042] Among them, the PEO used has a mo...

Embodiment 2

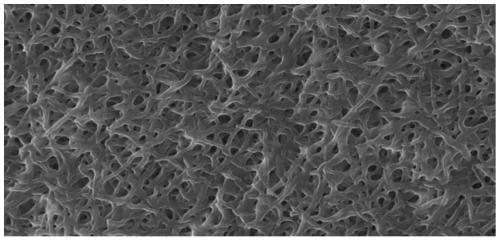

[0048] High permeability 10μ waterproof and moisture-permeable membrane production process, with a pore size of about 200nm

[0049] Production process: (PU spraying + electrospinning) - heating and curing film forming - fabric hot-melt lamination - washing and drying - finished product

[0050] Among them, the PU spraying + electrospinning drawing process is carried out by two spraying and three drawing methods. The ratio of process materials is: 0.5% PEO in the first section of electrospinning drawing, 40% PU + 2.5% PEO in the second section, and 40% PU + 2.5% PEO in the second section. Three sections of 60% PU+2% PEO; (by mass percentage)

[0051] Specific parameters: PEO electrospinning process, the first static voltage is 50KV, the second static voltage is 80KV, the third static voltage is 75KV, and the spinning height is 25cm; PU spraying process, the spray height is 30cm, and the spray particle size is 30-80 Micron.

[0052] Among them, PEO has a molecular weight of 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com