Medium-high temperature solar energy selective absorption coating layer and preparation method thereof

A technology that absorbs coatings and solar energy. It is applied in the field of photothermal solar energy to achieve good heat resistance, improve photothermal efficiency, and improve selective absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

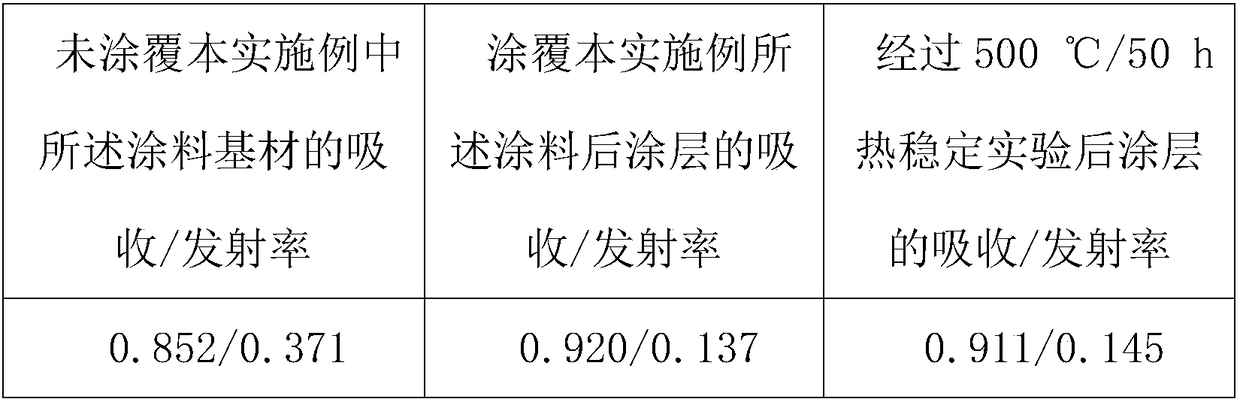

Embodiment 1

[0031] A medium and high temperature solar selective absorption coating, which consists of the following raw materials in parts by weight: 30 parts of organic silicon resin, CuCoMnO x 30 parts of functional powder, 20 parts of xylene, 5 parts of wetting and dispersing agent (1:1 ratio of disponer 904s and 583), 5 parts of anti-settling agent, 5 parts of leveling agent, 3 parts of defoaming agent, 2 parts of silane coupling agent share.

[0032]The preparation method of the medium and high temperature solar selective absorption coating is as follows:

[0033] (1) Preparation of absorbent pigment: raw material powder CuO, CoO, MnO 2 Sand-milling and mixing were carried out, and the composite agglomerated powder was prepared by spray granulation method. After the composite agglomerated powder was placed in a muffle furnace and calcined at 1000°C for 5 hours, CuCoMnO x Composite agglomeration functional powder;

[0034] (2) Take the raw materials by weighing the above-mentioned...

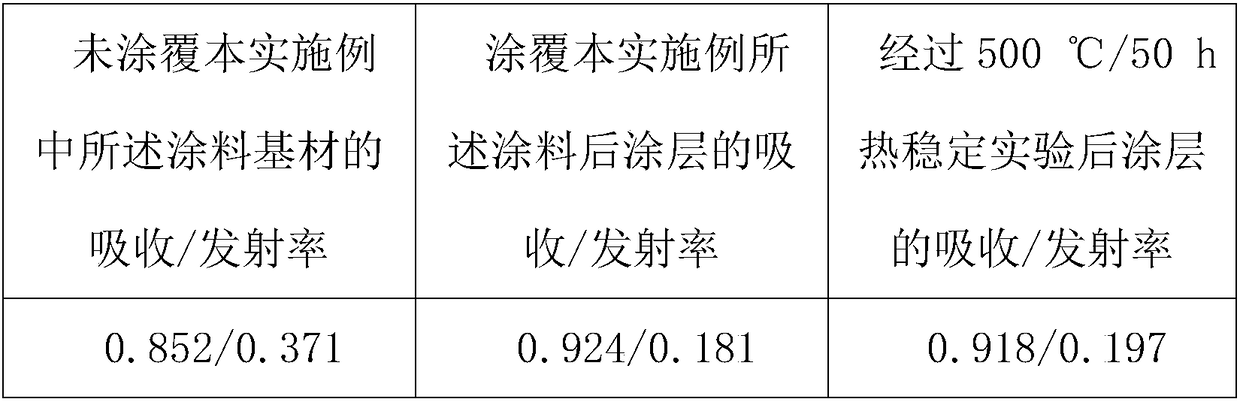

Embodiment 2

[0044] A medium-high temperature solar selective absorption coating formula, which consists of the following raw materials in parts by weight: 40 parts of silicone resin, CuCoMnO x 30 parts of functional powder, 20 parts of xylene, 2.5 parts of wetting and dispersing agent (1:1 between disponer 904s and 9250), 2.5 parts of leveling agent, 2 parts of leveling agent, 1.5 parts of defoamer, 1.5 parts of silane coupling agent share.

[0045] The preparation method of the medium and high temperature solar selective absorption coating is as follows:

[0046] (1) Preparation of absorbent pigment: raw material powder CuO, CoO, MnO 2 Sand-milling and mixing were carried out, and the composite agglomerated powder was prepared by spray granulation method. After the composite agglomerated powder was placed in a muffle furnace and calcined at 1000°C for 6 hours, CuCoMnO x Composite agglomeration functional powder;

[0047] (2) Take the raw materials by weighing the above-mentioned propo...

Embodiment 3

[0057] A medium-high temperature solar selective absorption coating formula, which consists of the following raw materials in parts by weight: 35 parts of silicone resin, CuCoMnO x 35 parts of functional powder, 15 parts of xylene, 3.75 parts of wetting and dispersing agent (disponer 904s), 3.75 parts of anti-settling agent, 4 parts of leveling agent, 2 parts of defoaming agent, and 1.5 parts of silane coupling agent.

[0058] The preparation method of the medium and high temperature solar selective absorption coating is as follows:

[0059] (1) Preparation of absorbent pigment: raw material powder CuO, CoO, MnO 2 Sand-milling and mixing were carried out, and the composite agglomerated powder was prepared by spray granulation method. After the composite agglomerated powder was placed in a muffle furnace and calcined at 1200°C for 5.5 hours, CuCoMnO x Composite agglomeration functional powder;

[0060] (2) Take the raw materials by weighing the above-mentioned proportioning b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com