Fluoroacrylate copolymer-containing coating material with high fluoride content and preparation method of coating material

A perfluoroalkyl ethyl acrylate and acrylate technology, which is applied in the field of materials, can solve the problem of poor gloss of fluorine coatings, and achieve the effects of reducing surface energy, improving gloss, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a high-fluorine content fluorine-containing acrylate copolymer coating material, comprising:

[0039] Step 1: Mix 75.6g of trifluoroethyl methacrylate (TFEMA), 32.9g of perfluorooctyl ethyl acrylate and 1.86g of hydroxyethyl acrylate, add to 235g of N,N-dimethylformamide, Stir well;

[0040] Step 2: Add 1.00 g of azobisisobutyronitrile (AIBN) to the solution in step 1 at a rate of 80 drops / min, heat up to 70° C. for polymerization, react for 12 hours, and cool down to stop the reaction;

[0041] Step 3: Completely dissolve the polymer obtained in Step 2 with N,N-dimethylformamide, add deionized water to the dissolved liquid for 3-5 precipitations, and dry in an oven at 100°C.

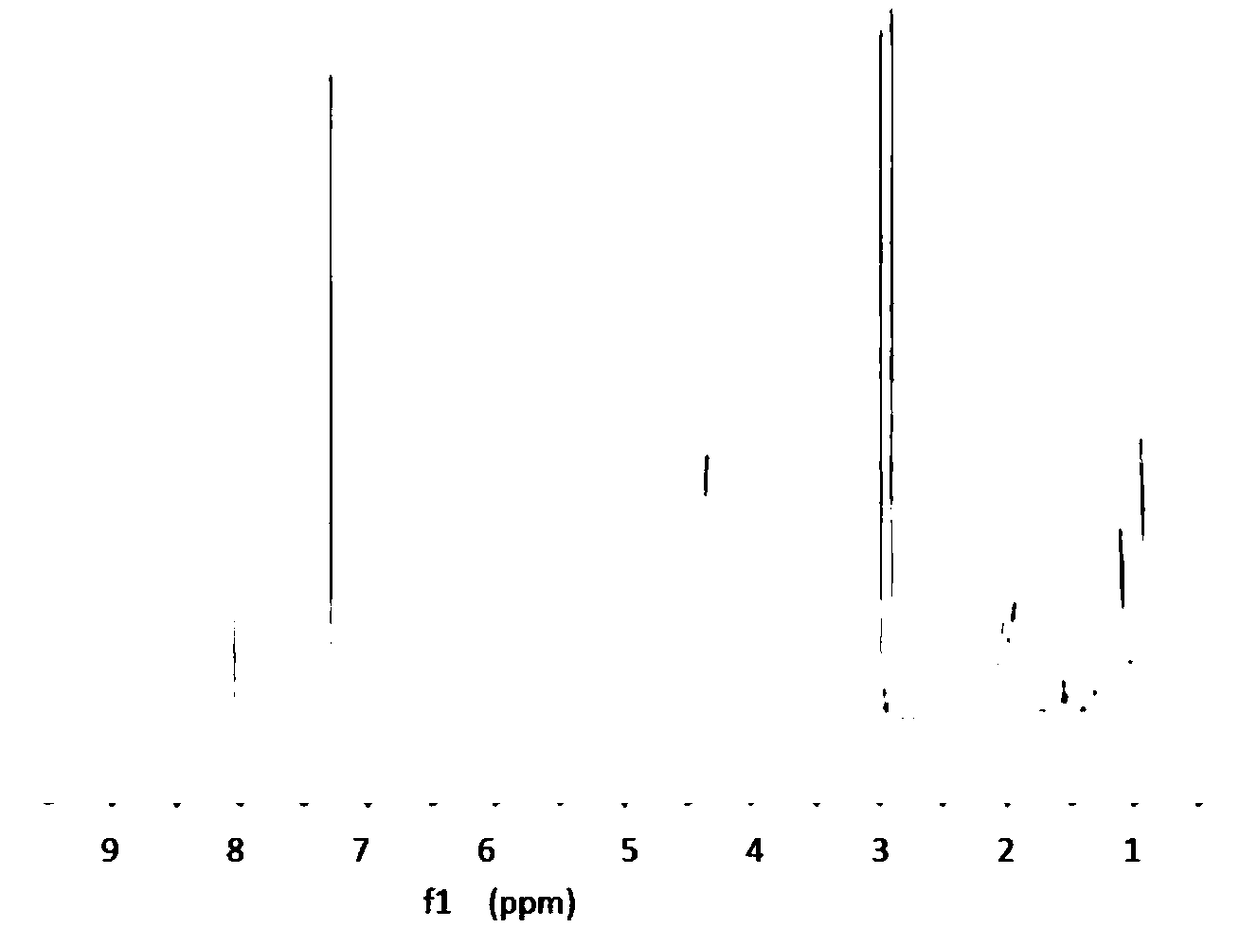

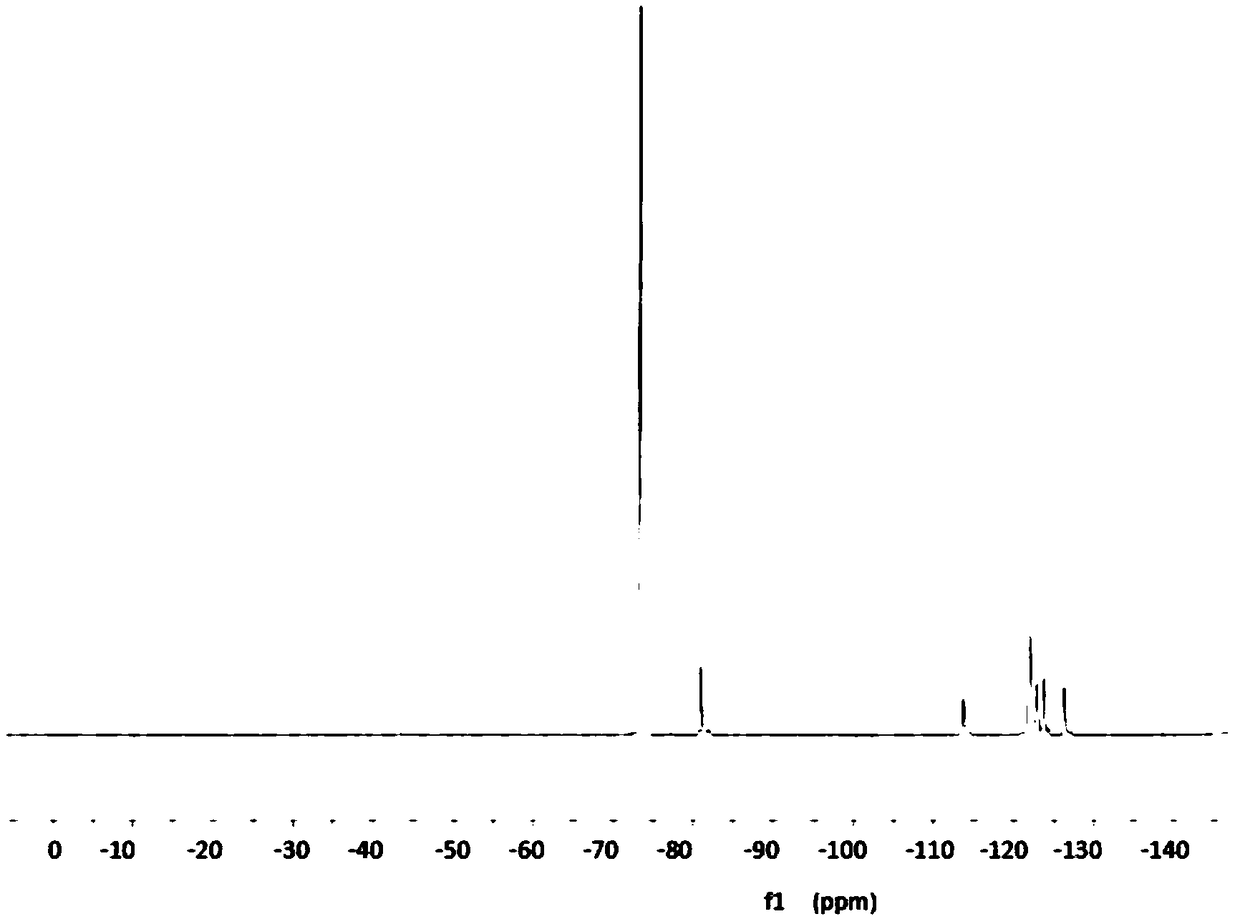

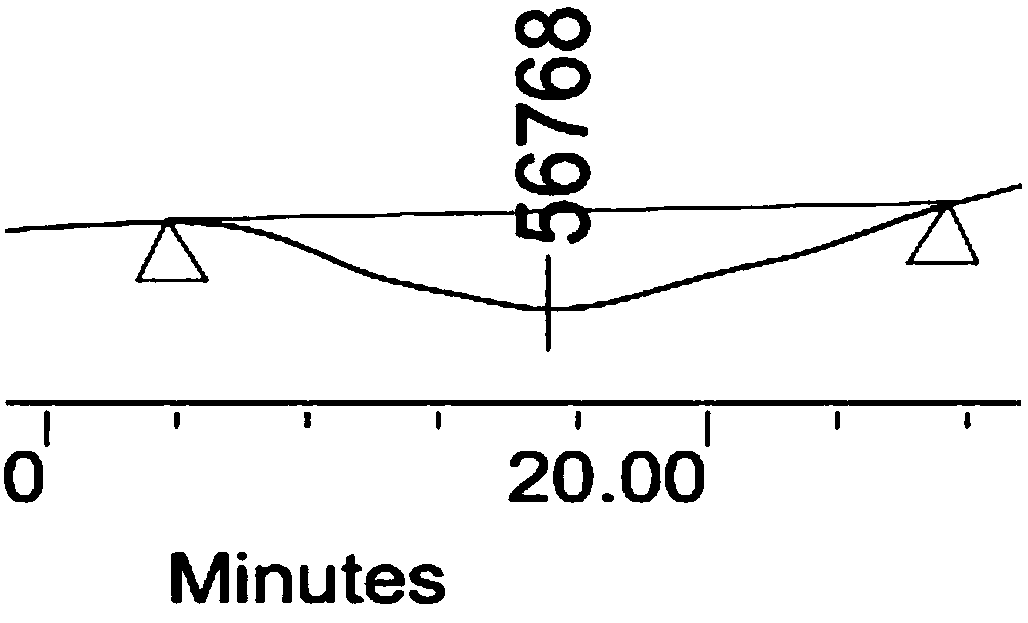

[0042] Gel Permeation Chromatography (GPC) is used to test the molecular weight of the fluoropolymer prepared in this embodiment. The test condition is that monodisperse polystyrene is used as molecular weight standard, tetrahydrofuran (THF) is used as mobile phase and sol...

Embodiment 2

[0047] A method for preparing a high-fluorine content fluorine-containing acrylate copolymer coating material, comprising:

[0048] Step 1: 75.6g of trifluoroethyl methacrylate (TFEMA), 267.6g of perfluorohexyl ethyl acrylate and 3.92g of hydroxyethyl acrylate (mixed, added to 235g of dichloromethane, stirred evenly;

[0049] Step 2: Add 1.50 g of azobisisobutyronitrile (AIBN) to the solution in step 1 at a rate of 100 drops / min, heat up to 70°C for polymerization, react for 12 hours, cool down to stop the reaction;

[0050] Step 3: Completely dissolve the polymer obtained in step 2 with dichloromethane, add deionized water to the dissolved liquid for 3-5 times to precipitate, and dry in an oven at 100°C.

[0051] The molecular weight of the fluoropolymer prepared in this example was determined to be 57826.

[0052] The resulting polymer had a fluorine content of 52.6%.

Embodiment 3

[0054] A method for preparing a high-fluorine content fluorine-containing acrylate copolymer coating material, comprising:

[0055] Step 1: Mix 75.6g of trifluoroethyl methacrylate (TFEMA), 551.2g of perfluorobutyl ethyl acrylate and 7.84g of hydroxyethyl acrylate, add TFEMA to the constant pressure low liquid funnel, and the perfluorobutyl Ethyl acrylate and hydroxyethyl acrylate were directly added to 235g of dimethyl sulfoxide, and 1.00g of tert-butyl peroxypivalate (TBPPI) was added to the solution, and stirred evenly;

[0056] Step 2: Gradually drop TFEMA into Step 1 at a rate of 80 drops / min, while raising the temperature to 70°C for polymerization;

[0057] Step 3: After all TFEMA is added dropwise, add 0.5g TBPPI again, react for 12 hours, cool down to stop the reaction;

[0058] Step 4: Completely dissolve the polymer obtained in Step 2 with dimethyl sulfoxide, add deionized water to the dissolved liquid for 3-5 precipitations, and dry in an oven at 100°C.

[0059] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com