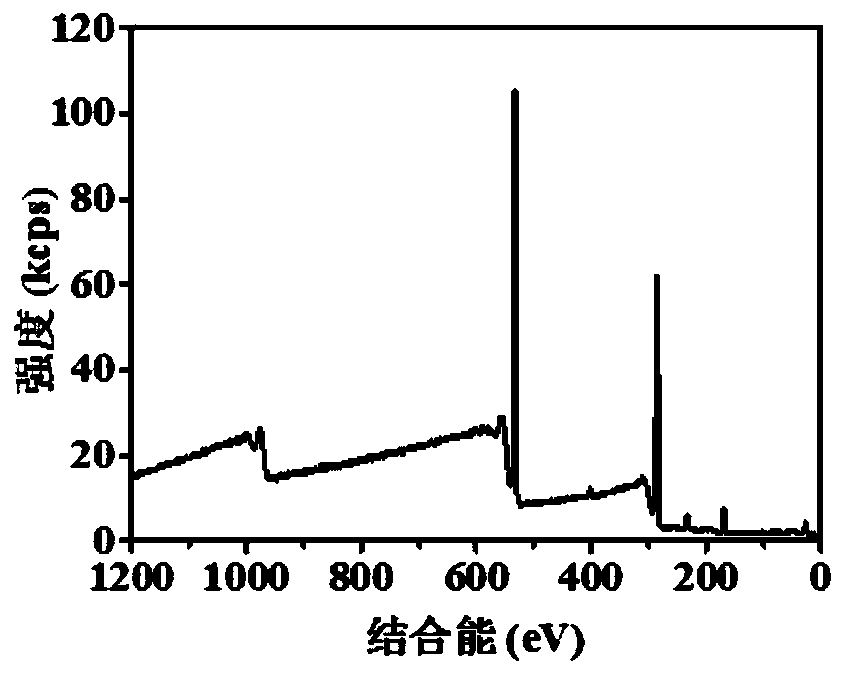

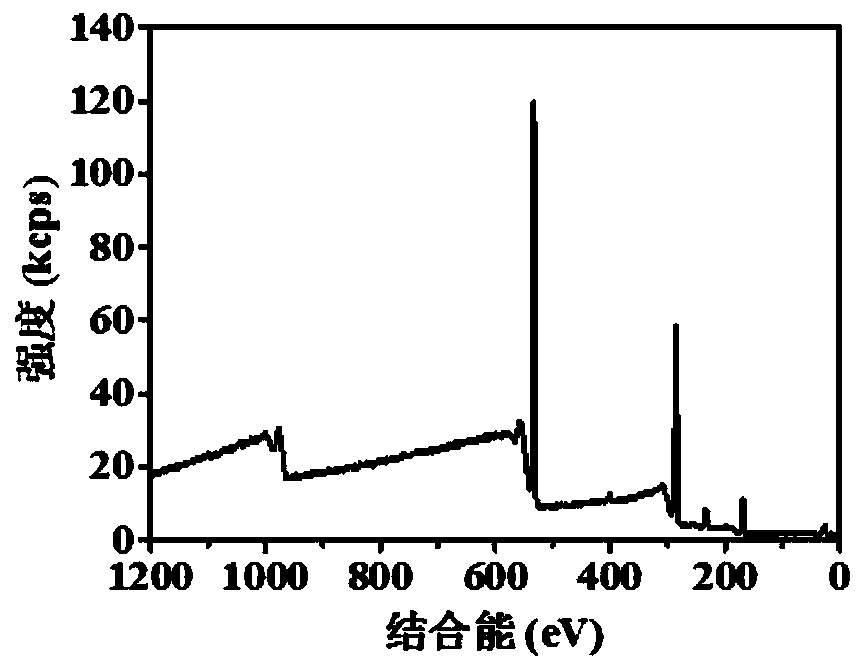

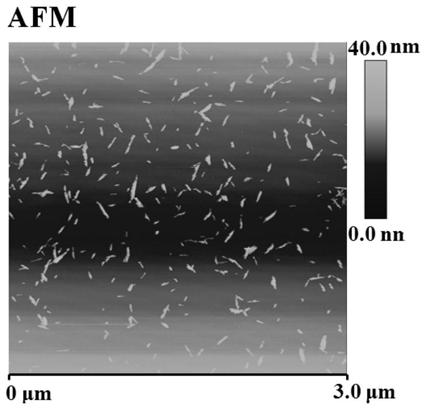

A kind of high sulfate group graft type cellulose nanocrystal and its preparation method and application

A sulfate group and nano-crystal technology, applied in the post-treatment of cellulose pulp, fiber raw materials, fiber raw material treatment, etc., can solve problems such as easy gelatinization, prevent mutual agglomeration, improve dispersion performance, and high Zeta-potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The waste paper produced in the production process of an enterprise is used to prepare high sulfate group grafted cellulose nanocrystals according to the following steps:

[0051] (1) Pulverization: After drying the waste paper, pulverize it with an ultrafine pulverizer for 6 minutes, and collect the paper scraps with a 60-mesh screen;

[0052] (2) Glycerol swelling: use glycerol to swell the paper scraps under stirring conditions (the mass ratio of glycerol to the paper scraps is 15:1), the stirring rate is 400rpm, and the temperature is 50°C ;

[0053] (3) Fiber separation and decolorization treatment: the swollen paper scraps of step (2) are dispersed into an aqueous solution containing 3.5% sodium hydroxide and 2% hydrogen peroxide (by weight) according to the mass ratio of 1:30 ), keeping the temperature at 60°C, stirring speed at 600rpm, reacting for 2h, the treated mixture was centrifuged and dehydrated, the solid obtained by centrifugation was dispersed with co...

Embodiment 2

[0060] The waste paper produced in the production process of an enterprise is used to prepare high sulfate group grafted cellulose nanocrystals according to the following steps:

[0061] (1) Pulverization: After the waste paper is dried, pulverize it with a superfine pulverizer for 10 minutes, and collect paper scraps with an 80-mesh screen.

[0062] (2) Glycerol swelling: the waste paper scraps were swollen under the condition of stirring, the stirring rate was 800 rpm, and the temperature was 55°C.

[0063] (3) Fiber separation and decolorization treatment: Disperse the swollen paper scraps obtained in step (2) into an aqueous solution containing 4% sodium hydroxide and 3% hydrogen peroxide according to a mass ratio of 1:40, and keep the temperature 65°C, stirring speed 1000rpm, reacting for 2.5h, the treated mixture was centrifuged and dehydrated, the solid obtained by centrifugation was dispersed with cold distilled water and then centrifuged and dehydrated. This kind of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com