Method for electrically degrading ceftazidime in water by adopting Fe3O4/biomass carbon cathode

A biomass carbon, ceftazidime technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. problem, to avoid secondary environmental pollution, low cost, and reduce the production of iron sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

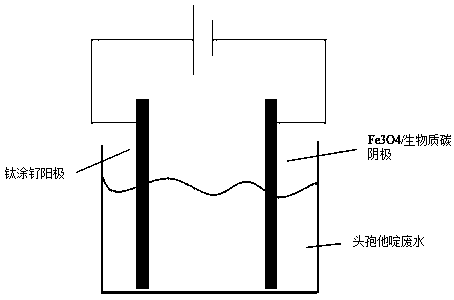

Method used

Image

Examples

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of Fe3O4 / biomass carbon in step 2 is 0.3:1, and the others are the same as Embodiment 1 or 2.

specific Embodiment approach 4

[0027] Specific embodiment four: the difference between this embodiment and one of the specific embodiments one to three is that the constant current density in step four is 30mA / cm 2 , and the others are the same as in one of the specific embodiments 1 to 3.

specific Embodiment approach 5

[0028] Specific embodiment five: this embodiment is different from one of specific embodiments one to four in that: the concentration of ceftazidime wastewater in step four is 10mg / L, and others are the same as one of specific embodiments one to four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com