A device and method for preparing water-based graphite by grinding and exfoliating

A graphite and water-based technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of unqualified product separation, reduce fluid rotation speed, short duration of action, etc., and achieve energy utilization, production capacity and product quality The effect of improvement, price reduction, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

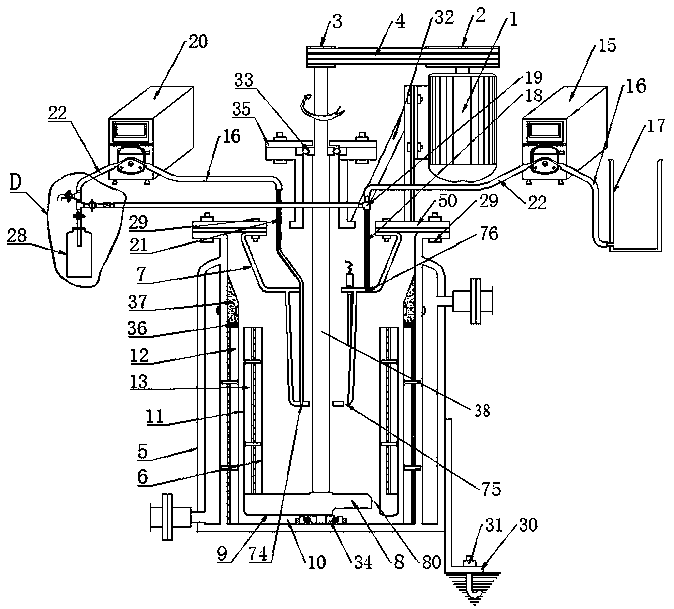

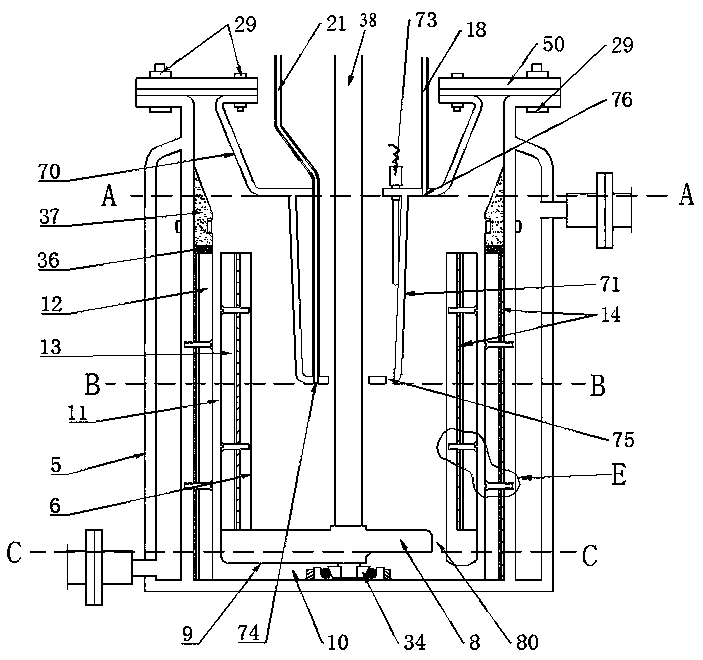

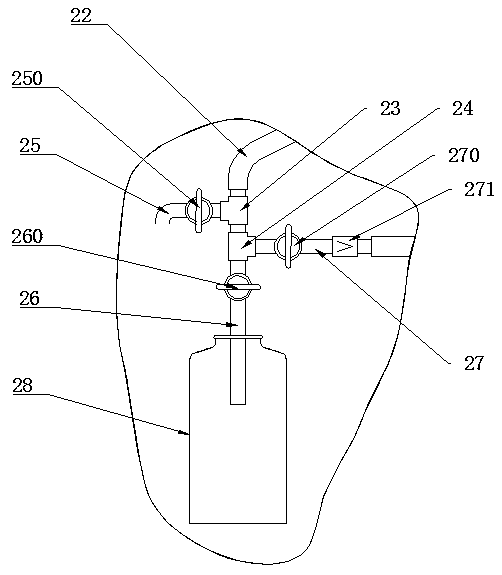

Method used

Image

Examples

Embodiment 1

[0070] The main parameters of the equipment in this embodiment are shown in Table 1, and the measured working volume is 4.36L. The power of the motor is 1.5kw, the diameter ratio of the driving wheel and the driven wheel is 2:1, and the distance between the moving grinding plate and the static grinding plate is 0.53mm.

[0071] Table 1 Main parameter table of the equipment in this embodiment

[0072]

[0073] It can produce 0.64kg of qualified water-based graphite cold stamping release agent raw materials per hour, and its graphite content is 9.86%. The TEM photo of the product is as follows Figure 9 and Figure 10 shown. The system temperature was 37.2°C.

Embodiment 2

[0075] The main parameter of present embodiment equipment, operating process are with embodiment 1, but 98% sulfuric acid consumption is 5% of N-methylpyrrolidone weight, and graphite consumption is 15% of above-mentioned solution.

[0076] In this embodiment, 0.83kg of qualified water-based graphite cold stamping release agent raw material can be produced per hour, and its graphite content is 15.07%. The product TEM photo and Figure 9 and Figure 10 Much the same. The system temperature was 54.5°C.

Embodiment 3

[0078] When the static grinding plate is installed, an adjusting gasket is added so that the gap between the dynamic grinding plate and the static grinding plate is 0.2 mm. The main parameters, assembly process and operation process of other equipment are the same as in Embodiment 1.

[0079] In this example, 0.76 kg of qualified water-based graphite cold stamping release agent raw material can be produced per hour, the graphite content is 10.51%, and the system temperature is 62.6°C. It can be seen that there is a loss of solvent volatilization. However, the time from feeding materials to qualified products is significantly shortened. Considering the wear of bearings and grinding discs, the high-content graphite experiment was not carried out. Product TEM photos with Figure 9 and Figure 10 Similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com