Fine multi-stage automatic cyclic crushing device and working process thereof

A technology of automatic circulation and pulverization device, applied in chemical instruments and methods, solid separation, sieve and other directions, can solve the problems of increasing the cost of powder sieve and reducing work efficiency, and achieves the improvement of fineness, work efficiency and reduction of production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

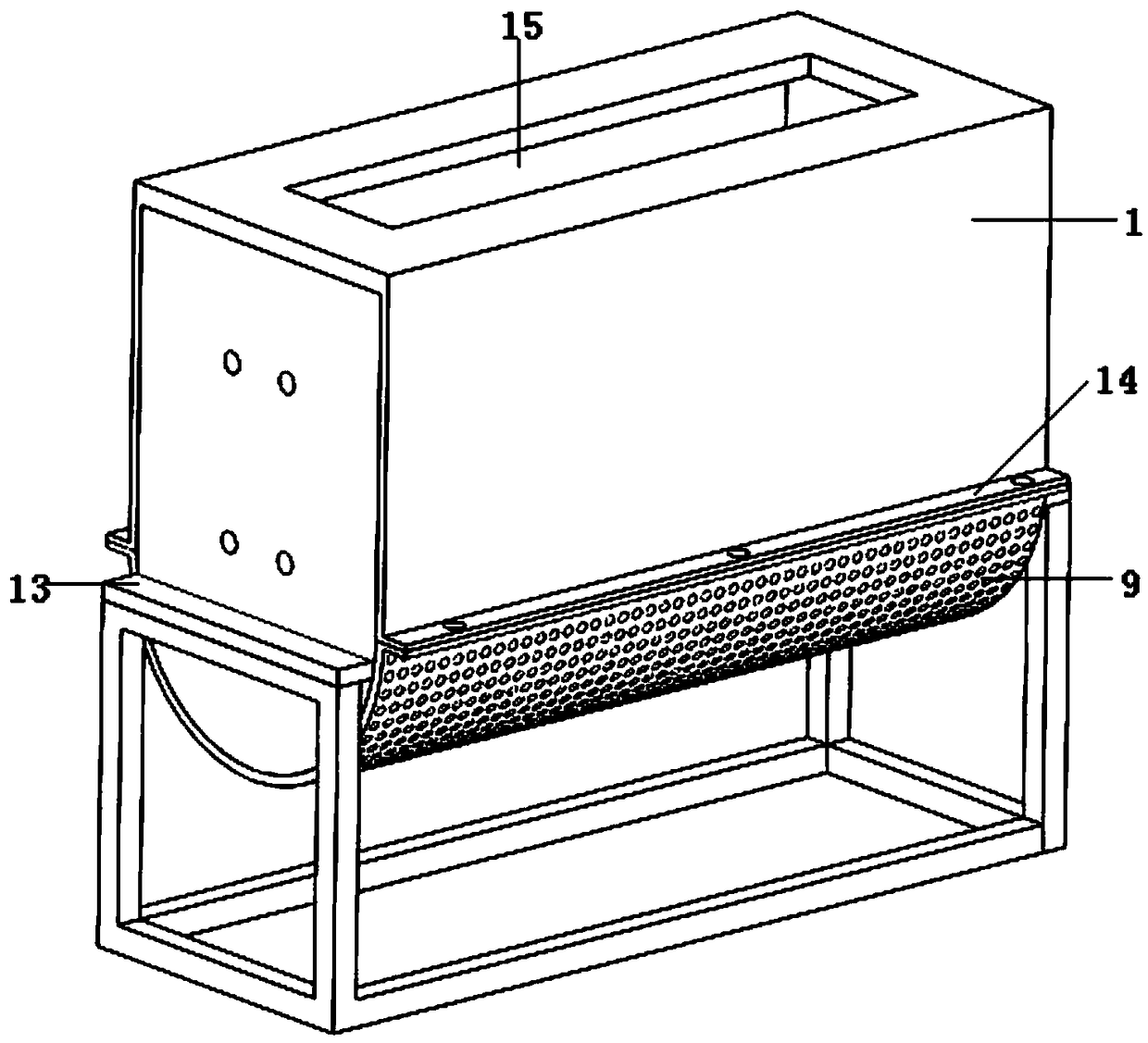

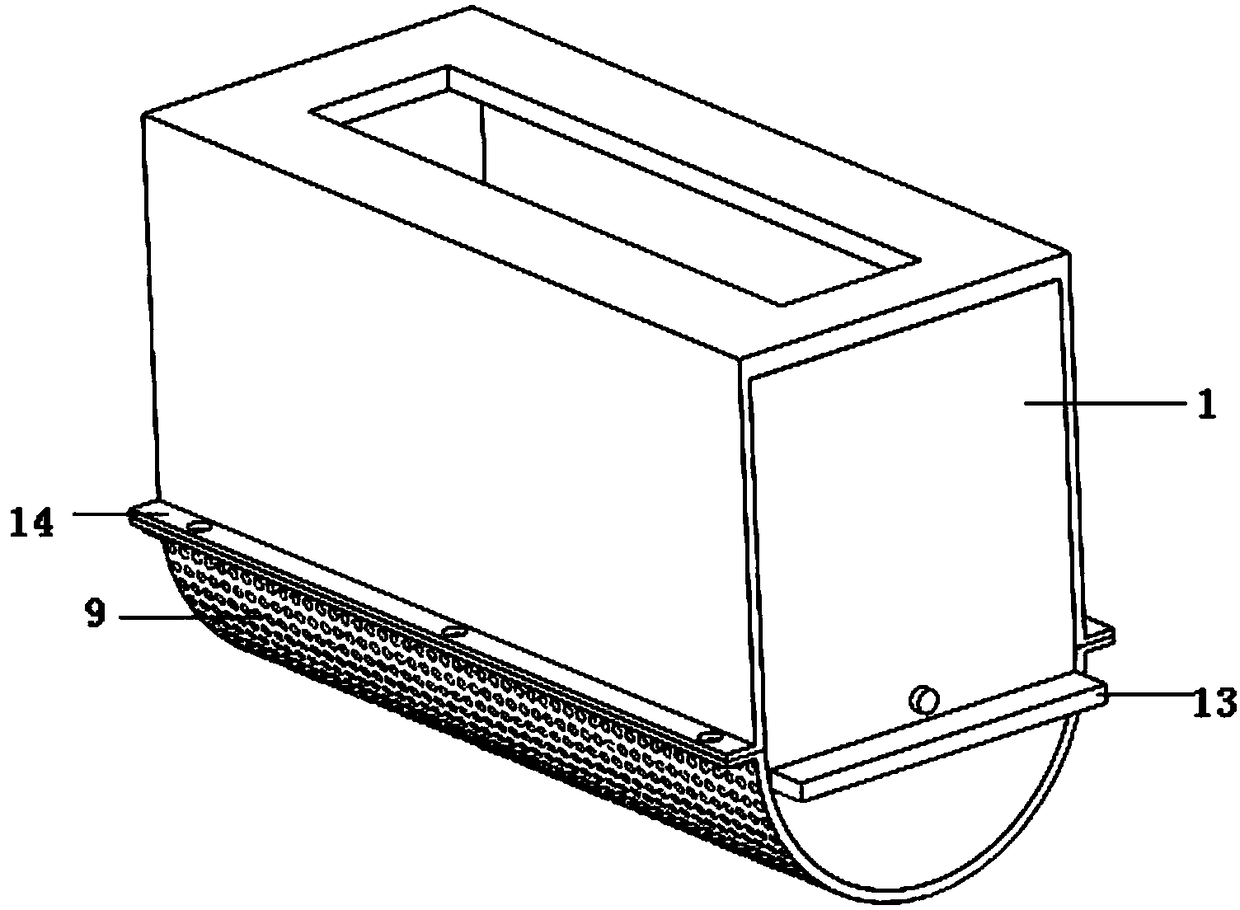

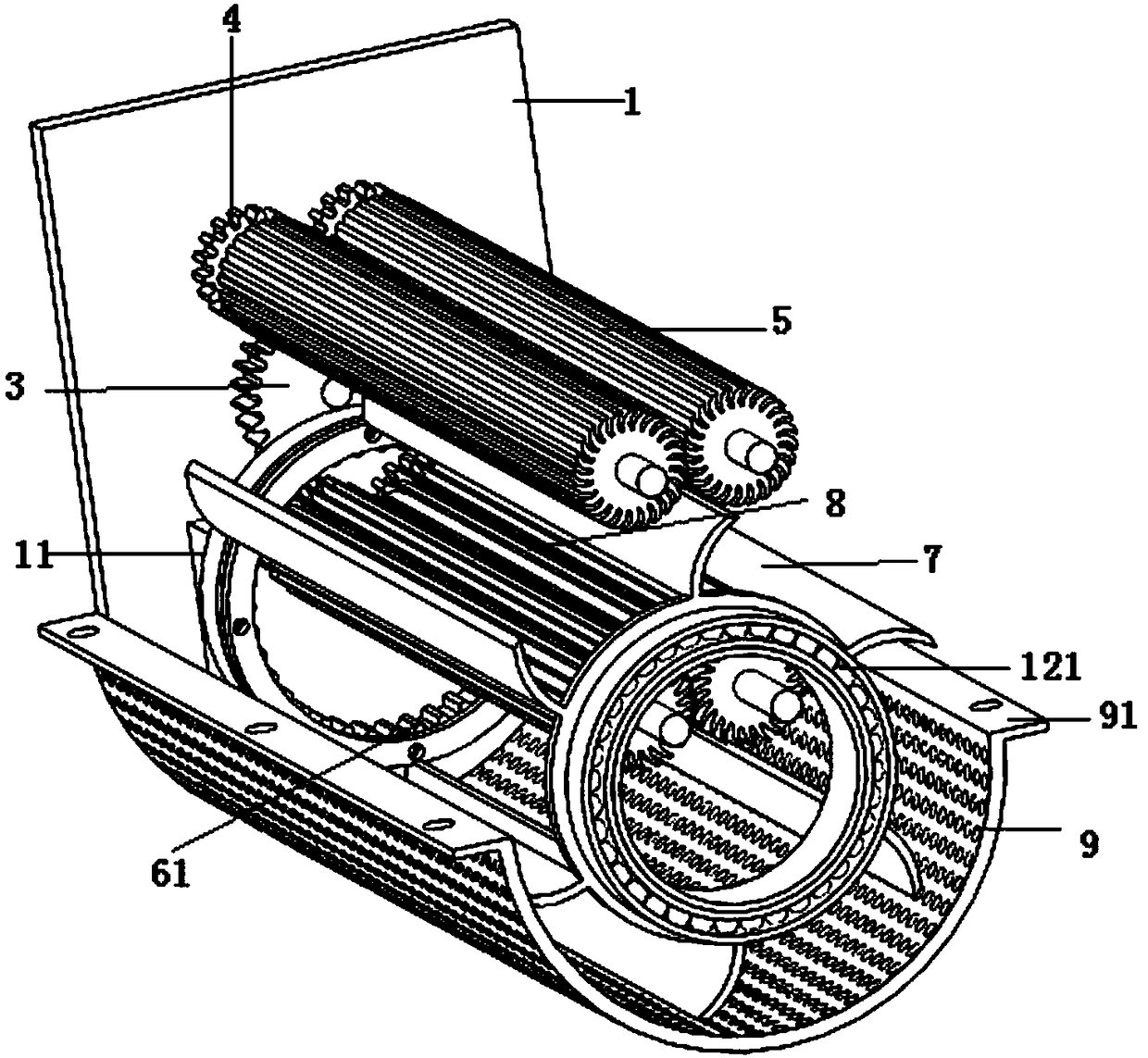

[0031] A refined multi-stage automatic circulation crushing device, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the crushing box 1 is included, and the crushing box 1 is fixed on the support frame. The bottom end of the left side wall of the crushing box 1 is equipped with a first rotating shaft. One end of the first rotating shaft is connected to the motor, and the other end is connected to the first transmission. Gear 2, the side wall of the crushing box 1 is equipped with a second transmission gear 3 meshing with the first transmission gear 2, and at the same time, the top of the crushing box 1 is fixed with two first gears that are both meshed with the second transmission gear 3 Power gear 4, two primary crushing rollers 5 that are engaged with each other are installed and fixed on the two first power gears 4;

[0032] The bottom end of the left side wall of the crushing box 1 is fixed with a support platform 11, and the sun gear group 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com