A kind of regeneration method of active alumina defluorination agent

A technology of activated alumina and fluorine removal agent, which is applied in the field of smelting flue gas purification and environmental protection, can solve the problems of unable to guarantee the stable recycling of alumina, large loss of alumina, and low regeneration efficiency, so as to maintain good adsorption performance and reduce Alumina loss and effect of improving regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

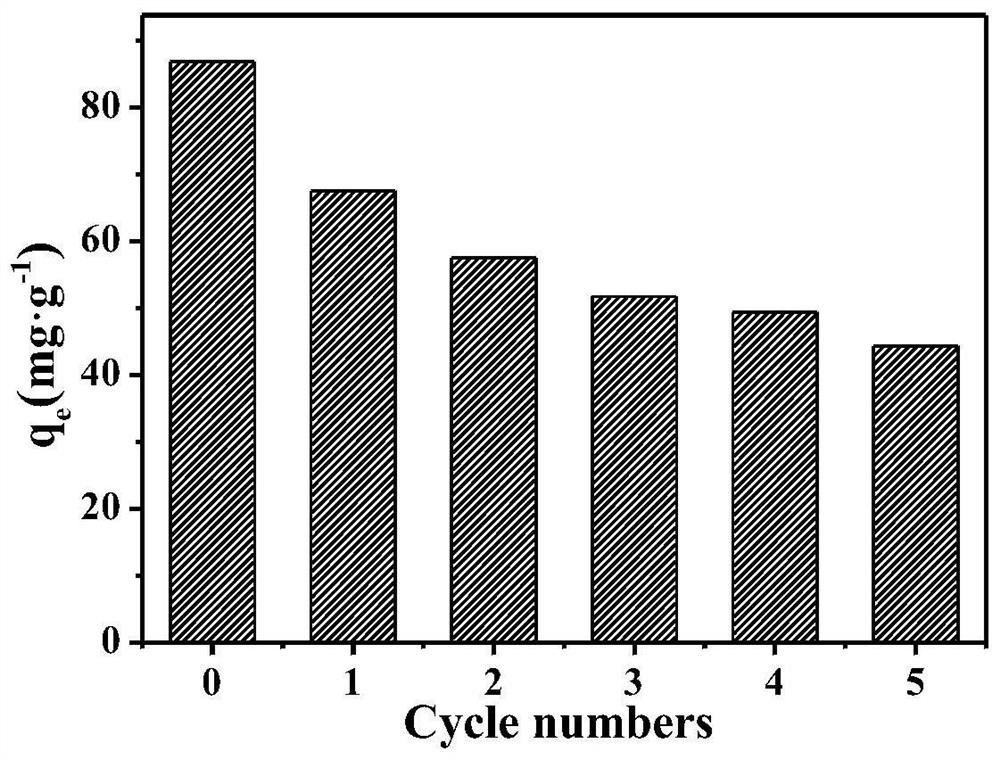

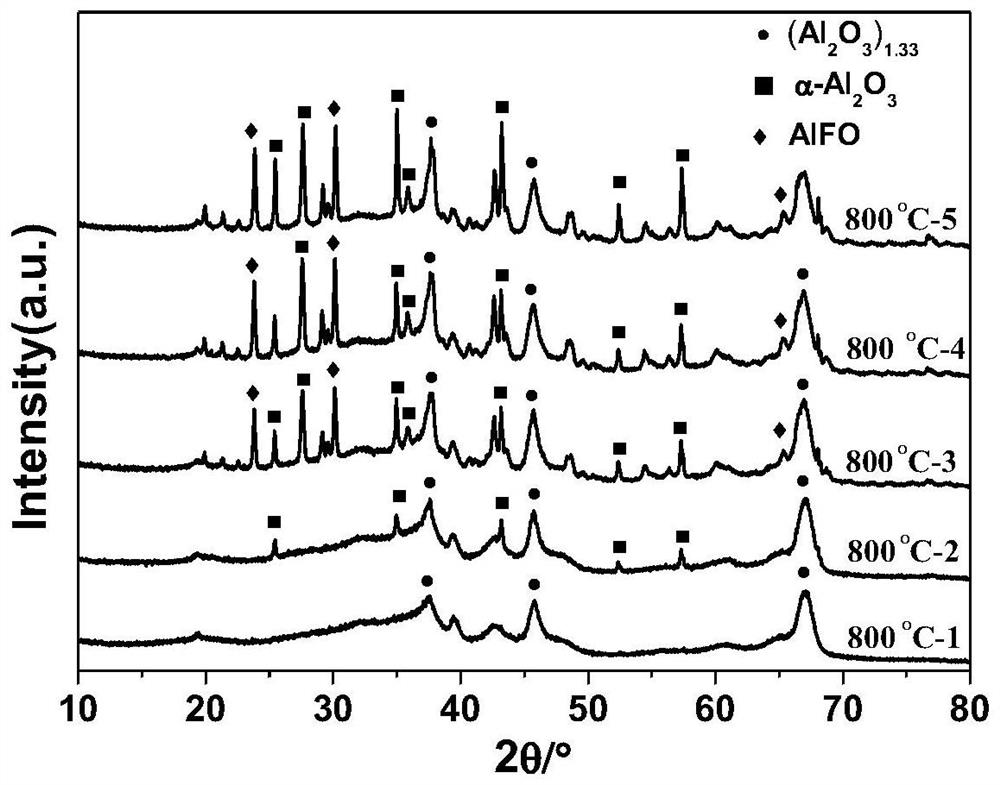

[0025] A method for regenerating an activated alumina defluorination agent, which uses saturated adsorbed activated alumina as the treatment object, and its specific steps include:

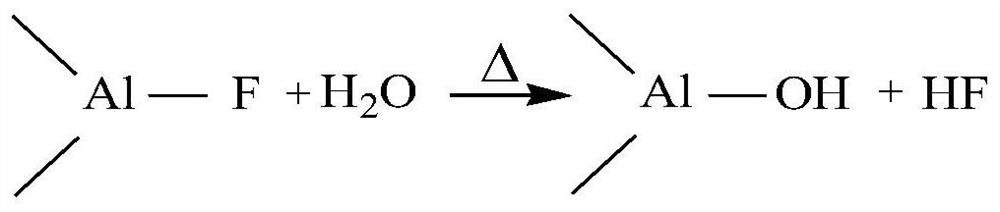

[0026] (1) Place the quartz boat containing the activated alumina in a tube furnace, and continue to -1 The speed is passed into the mixed gas of nitrogen and water vapor, and the volume fraction of water vapor in the said mixed gas is 10%;

[0027] (2) Set the tube furnace at 5°C·min -1 The temperature is raised to 200°C at a rate of 60 minutes, and then 10°C·min -1 Raise the temperature at a rate of 500°C to the regeneration temperature and keep it warm for 1 hour. The tail gas produced is absorbed by the water in the absorption bottle and collected for recycling. After the heating is completed, the ventilation is stopped, and the regenerated alumina is obtained by naturally cooling to room temperature.

[0028] The removal rate of fluorine was calculated by detecting the content of fluorine i...

Embodiment 2

[0030] This example differs from Example 1 only in that the regeneration temperature is 600°C. The removal rate of fluorine was calculated by detecting the content of fluorine in the sample by XRF, and the results are shown in Table 1.

Embodiment 3

[0032] The only difference between this embodiment and embodiment 1 is that the regeneration temperature is 700 degrees. The removal rate of fluorine was calculated by detecting the content of fluorine in the sample by XRF, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com