Device for regenerating potassium ion sieve through electric driving method and application of device

A potassium ion, electric drive technology, applied in the field of potassium extraction from seawater, can solve the problems of incomplete regeneration, low efficiency, cumbersome steps, etc., and achieve the effect of high strength and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

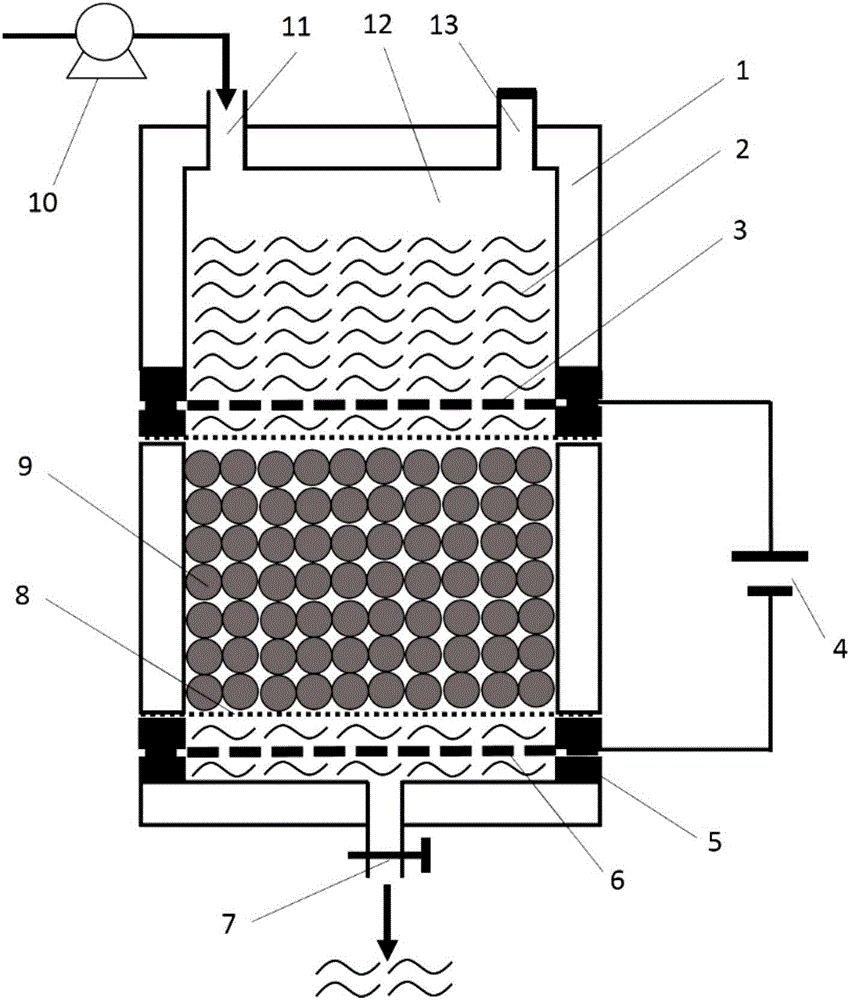

[0110] Embodiment 1: Electric drive method regeneration potassium ion sieve device of the present invention

[0111] The implementation mode of this embodiment is as follows:

[0112] The device for regenerating the potassium ion sieve by the electric drive method of the present invention comprises a tank body 1 , a regenerating liquid outlet 7 and a regenerating liquid inlet 13 . The device also includes stainless steel mesh anode 3, DC stabilized power supply 4, silicone gasket 5, stainless steel mesh cathode 6, polyester filter cloth 8, potassium ion sieve 9, air pump 10 and air inlet 11;

[0113] Tank body 1 is a cylinder made of plexiglass with a ratio of height to diameter of 1:5. The tank body 1 is composed of an upper tank body 1-1, a lower tank body 1-2 and a tank bottom 1-3; an air inlet 11 connected to an air pump 10 and a regeneration liquid inlet 13 are arranged on the top of the upper tank body 1-1; The regeneration liquid outlet 7 is set in the center of the t...

Embodiment 2

[0118] Embodiment 2: Electric drive method regeneration potassium ion sieve device of the present invention

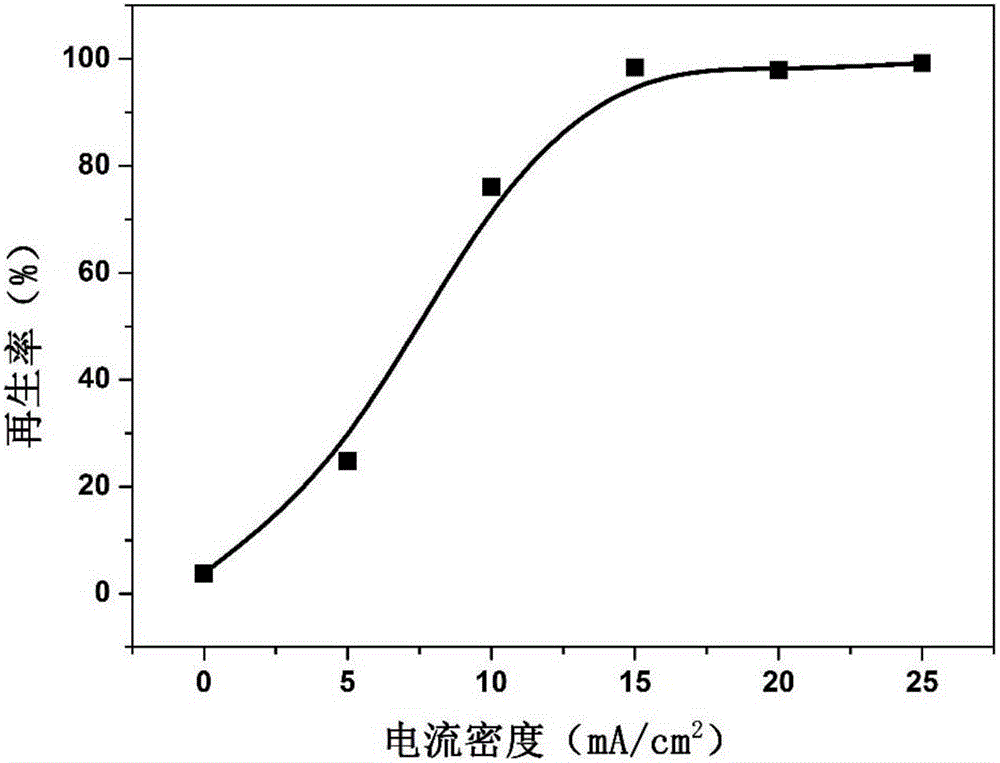

[0119] The implementation mode of this embodiment is the same as embodiment 1, except that the tank body 1 is a cylinder made of plexiglass or stainless steel with a ratio of height and diameter of 1:8, and the mesh size is installed in the silica gel sealing gasket 5-1. 100-mesh stainless steel mesh anode 3; the mesh size is 100 mesh stainless steel mesh cathode 6 installed in the silica gel sealing gasket 5-2; the voltage of the DC stabilized power supply 4 is 12V, and the current density is 16mA / cm 2 . The concentration in the tank body 1 is to form an air chamber 12 between the 2 liquid levels of the 4% sodium nitrate aqueous solution by weight and the upper end of the upper tank body 1-1; the distance between the 2 liquid levels of the regeneration liquid and the stainless steel mesh anode 3 is 5 times the height of potassium ion sieve 9.

Embodiment 3

[0120] Embodiment 3: Electric drive method regeneration potassium ion sieve device of the present invention

[0121] The implementation mode of this embodiment is the same as embodiment 1, except that the tank body 1 is a cylinder made of plexiglass or stainless steel with a ratio of height and diameter of 1:10, and the mesh size is installed in the silica gel sealing gasket 5-1. 400-mesh stainless steel mesh anode 3; a mesh size of 1000-mesh stainless steel mesh cathode 6 is installed in the silicone gasket 5-2; the voltage of the DC stabilized power supply 4 is 18V, and the current density is 12mA / cm 2 . The concentration in the tank body 1 is to form an air chamber 12 between the 10% sodium sulfate aqueous solution regeneration liquid 2 liquid level and the upper tank body 1-1 upper end by weight; the distance between the regeneration liquid 2 liquid level and the stainless steel mesh anode 3 is 4 times the height of potassium ion sieve 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com