High-performance forward osmosis membrane as well as preparation method and application thereof

A high-performance technology of forward osmosis membrane, applied in the field of osmosis membrane, can solve the problems of low water flux and low efficiency of heavy metal wastewater, and achieve the effect of improving water flux and promoting heavy metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

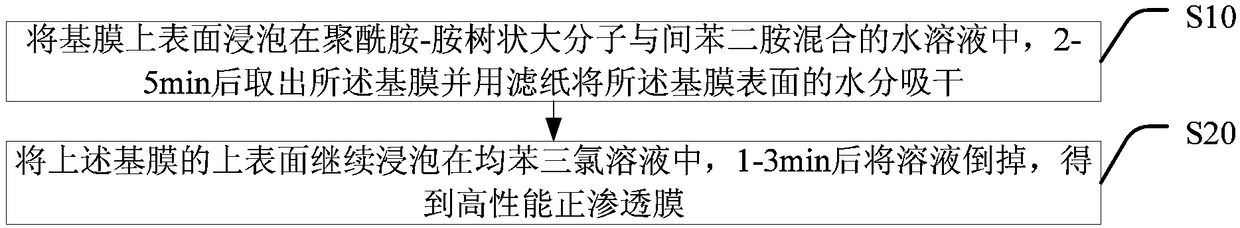

[0031] see figure 1 , figure 1 It is a flowchart of a preferred embodiment of a method for preparing a high-performance forward osmosis membrane of the present invention, as shown in the figure, including steps:

[0032] S10. Soak the upper surface of the basement membrane in an aqueous solution mixed with polyamide-amine dendrimers and m-phenylenediamine, take out the basement membrane after 2-5 minutes and dry the solution on the surface of the basement membrane with filter paper;

[0033] S20. Continue soaking the upper surface of the base membrane obtained in step S10 in the tris-trichloride solution, and pour off the solution after 1-3 minutes to obtain a high-performance forward osmosis membrane.

[0034] Specifically, polyamide-amine dendrimers can be used to modify the polyamide layer of the membrane due to their radial symmetry, hyperbranched structure, large number of terminal functional groups, and approximately spherical molecular structure. Through chemical modi...

Embodiment 1

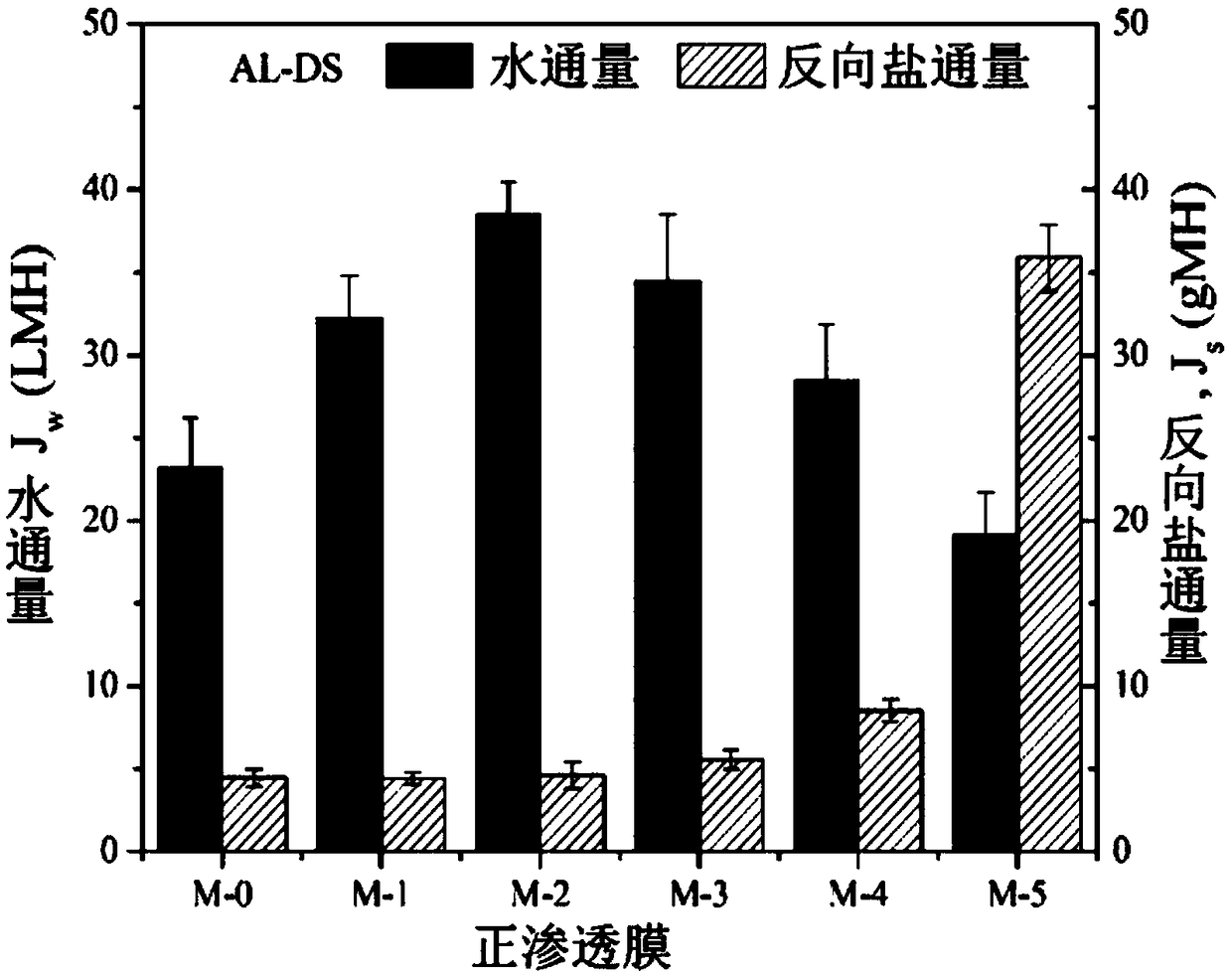

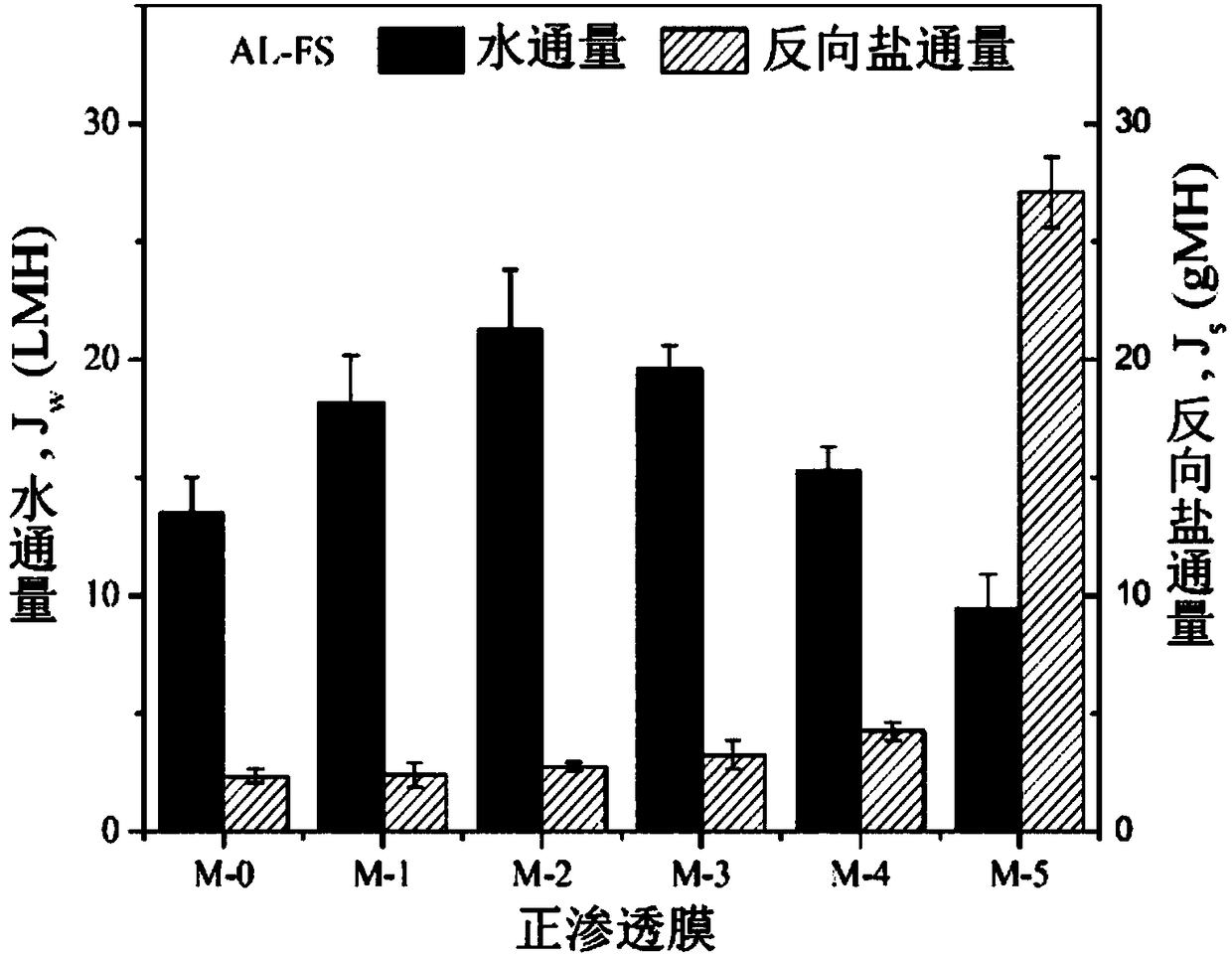

[0049] A PAMAM-modified composite forward osmosis membrane (TFC-type FO membrane) was prepared by interfacial polymerization of a mixed aqueous solution of PAMAM and m-phenylenediamine (MPD) and trimesistrichloride (TMC) on a polyvinylidene fluoride-based membrane.

[0050] 1), prepare the mixed aqueous solution of the PAMAM of four kinds of different mass concentrations and MPD, the mass concentration of described PAMAM is respectively 0.1%, 0.2%, 0.3% and 0.4%, the mass concentration of described MPD is 2%;

[0051] 2), completely immerse the upper surface of the polyvinylidene fluoride-based membrane in the above-mentioned four mixed aqueous solutions of PAMAM and MPD with different mass concentrations, pour off the solution after 2 minutes, and remove the solution remaining on the surface of the base membrane with filter paper;

[0052] 3) The upper surface of the basement membrane soaked in the mixed aqueous solution of PAMAM and MPD was immersed in a n-hexane solution wit...

Embodiment 2

[0055] A PAMAM-modified TFC-type FO membrane was prepared by interfacial polymerization on a polyvinylidene fluoride-based membrane with a mass concentration of 1.0% PAMAM aqueous solution (excluding MPD) and trimesistrichloride (TMC), denoted as M-5, Its preparation steps are similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com