A surface treatment appliance, a filter and components therefor

A filter assembly and throat technology, applied in the field of surface treatment tools, can solve the problems that the machine can not provide suction, the bypass valve is blocked by dirt, etc., and achieve the effect of good centripetal dust separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

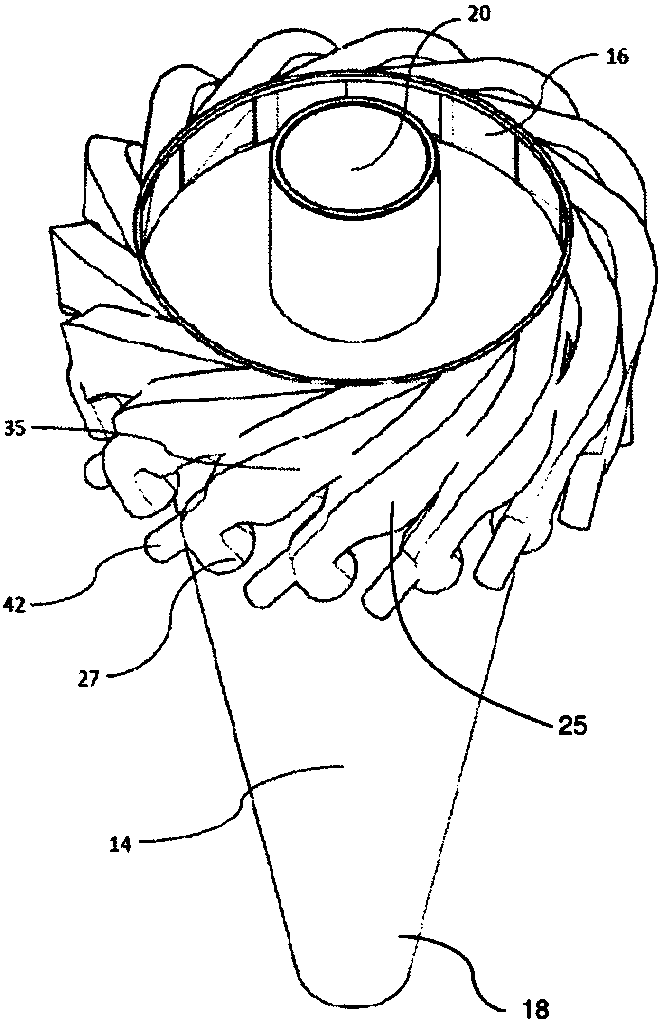

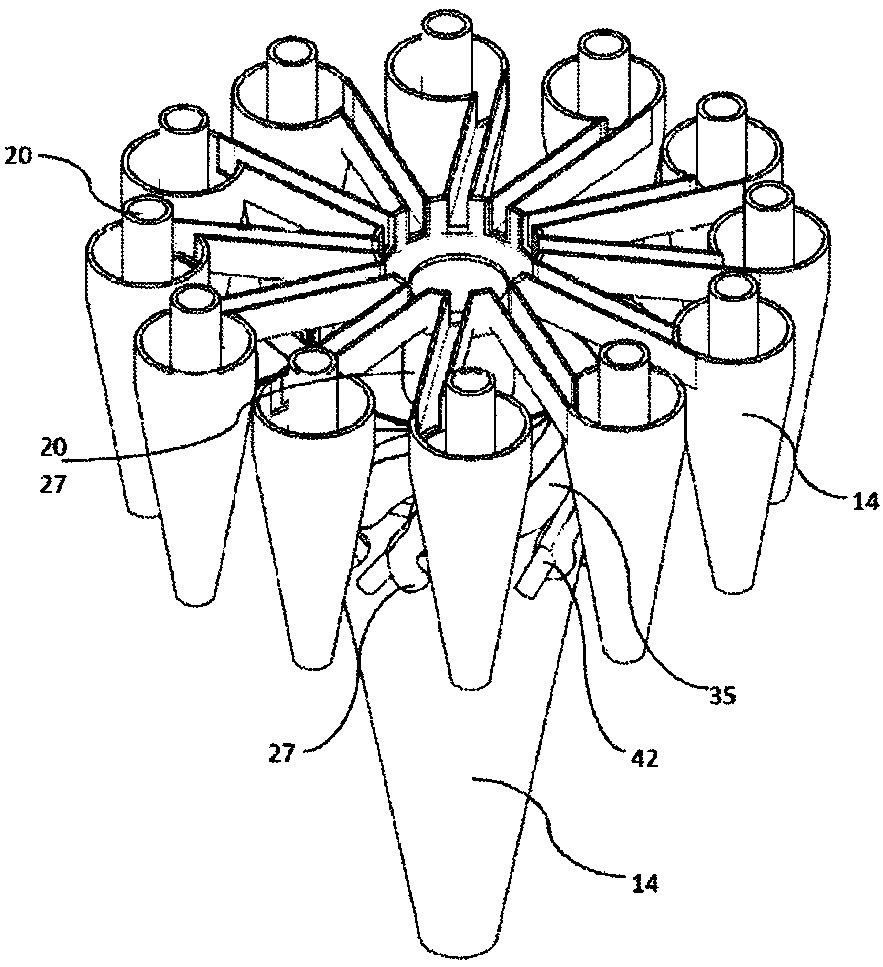

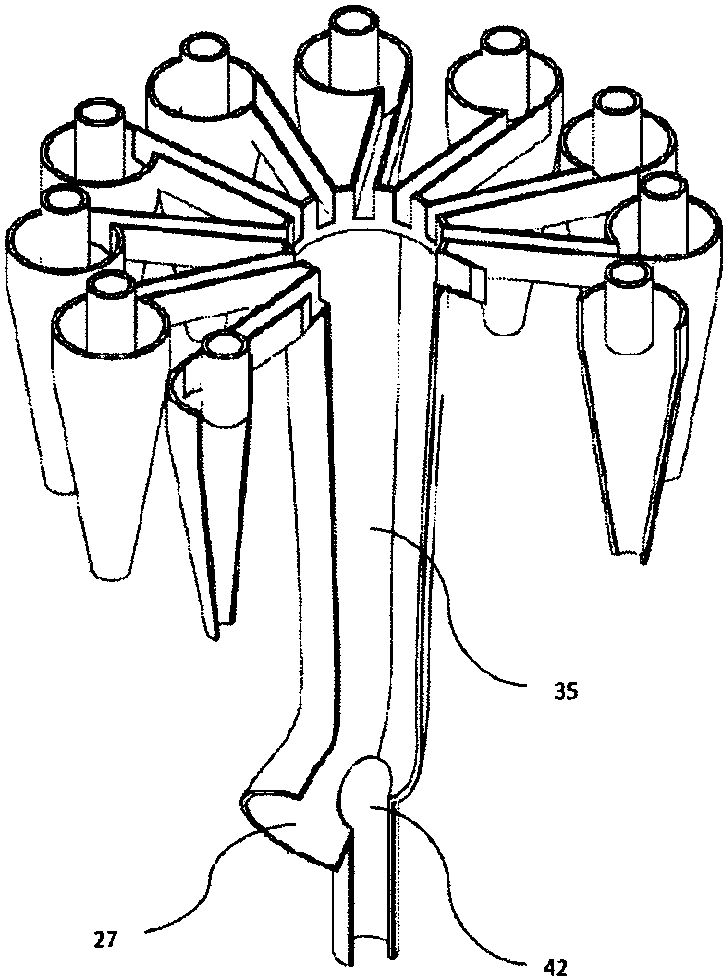

[0173] Figure 1 to Figure 3 and Figure 28 A cyclonic filter assembly unit 14 is shown whose air flow and suction can be increased when it is provided with a tangentially arranged injector unit 25 mounted around the rim periphery of the cyclone 14 .

[0174] The cyclone filter assembly unit 14 is configured to be installed in a vacuum cleaner (not shown), and the cyclone filter assembly unit 14 includes a housing ( Figure 28 99 in , but for clarity, in figure 1 ), the housing has a housing inlet 98 for the dirty air flow and a housing outlet 97 for the filtered air flow. Mounted in the housing 99 is a cyclone separator 14 having a plurality of cyclone inlets 16 , a dirt outlet 18 , and a clean air outlet 20 in fluid communication with the housing outlet 97 . There are a plurality of injector units 25 configured to deliver a flow of clean air from the exterior of the housing 99 and dirty air from the interior of the housing to the one or more cyclone inlets 16 . Each inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com