Patterned wetting surface processing method

A surface processing and patterning technology, which is applied in the field of metal surface treatment and modification, can solve the problems of poor precision, wettability patterned surface complexity, expensive equipment, etc., and achieves strong versatility, low cost and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

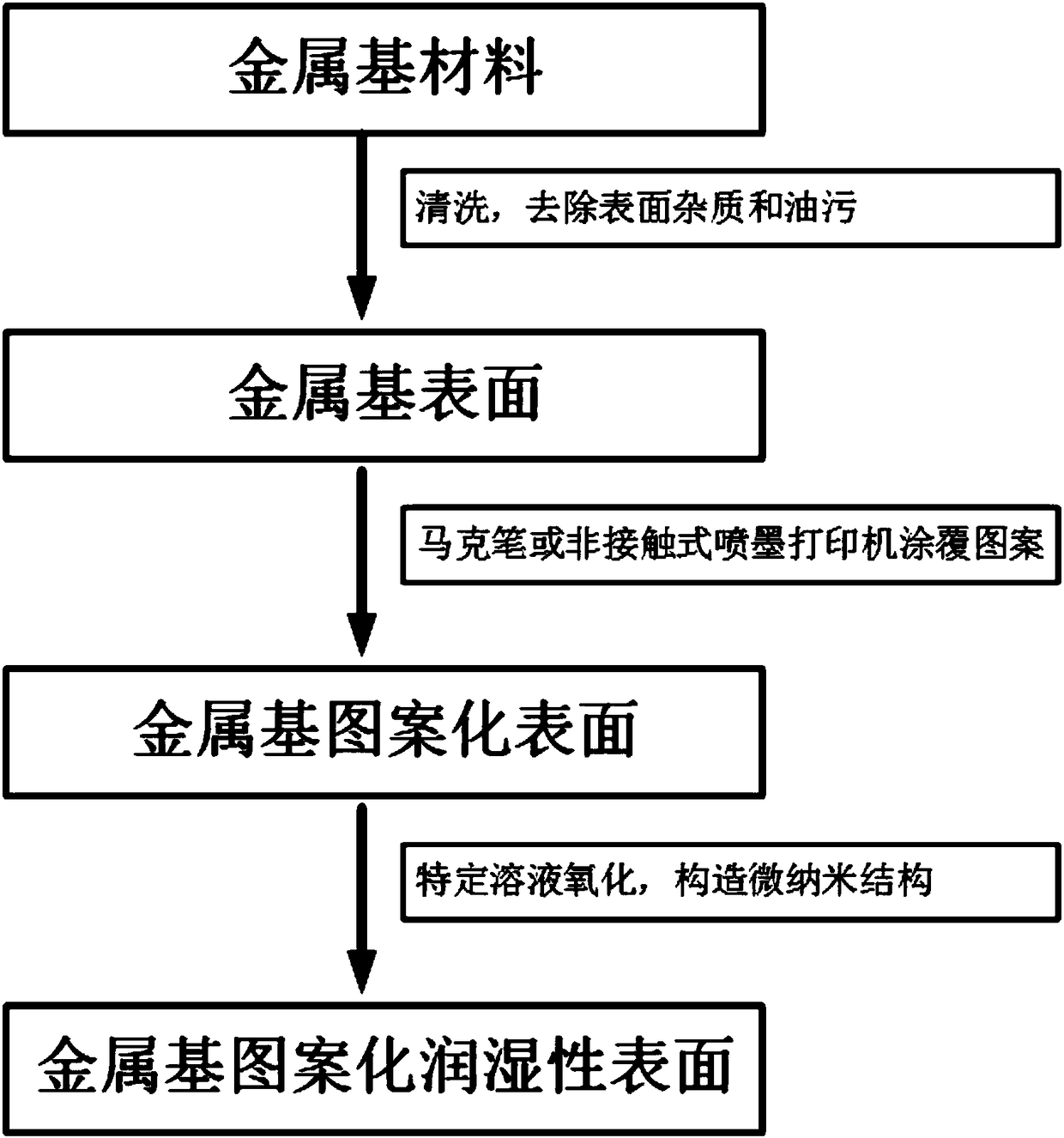

[0025] Using the method of the present invention to perform wettable patterned surface processing on the copper substrate, the process of the present invention is as follows figure 1 shown, the specific steps are as follows:

[0026] (1) Surface pretreatment of copper plate: Put the copper plate into 1M acetic acid solution to corrode for 1 minute, take it out and dry it with nitrogen to remove the dirt and oxide layer on the surface of the copper plate.

[0027] (2) Coating the desired pattern: Use a marker or a non-contact inkjet printer to coat the actual desired pattern on the surface of the copper plate obtained in step (1).

[0028] (3) Selective oxidative corrosion: The copper plate with the pattern obtained in step (2) is put into a mixed solution of 0.1M ammonium persulfate and 0.1M sodium bicarbonate to react for 24h.

[0029] (4) Surface cleaning and drying: put the copper sheet treated in step (3) into an acetone solution for cleaning, and then dry it in the air. ...

Embodiment 2

[0031] Using the method of the present invention to perform wettable patterned surface processing on the aluminum substrate, the process of the present invention is as follows figure 1 shown, the specific steps are as follows:

[0032] (1) Surface pretreatment of aluminum plate: Use 600# and 1000# sandpaper to polish the aluminum plate, and then place it in deionized water for ultrasonic vibration cleaning to remove grease and impurities on the surface of the aluminum substrate.

[0033] (2) Coating the desired pattern: Use a marker or a non-contact inkjet printer to coat the actual desired pattern on the surface of the aluminum plate obtained in step (1).

[0034] (3) Selective oxidative corrosion: The aluminum plate with the pattern obtained in step (2) is put into a copper chloride solution with a concentration of 1M for reaction for 5s.

[0035] (4) Surface cleaning and drying: put the aluminum plate treated in step (3) into deionized water for ultrasonic cleaning, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com