Energy-absorbing method based on hybrid dynamic polymer

A polymeric, dynamic technology for energy-absorbing applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

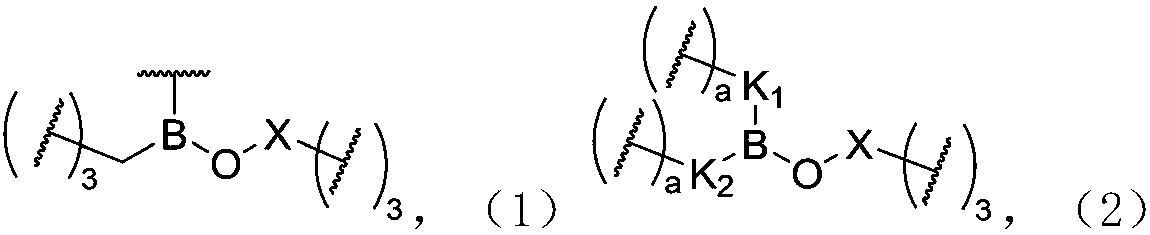

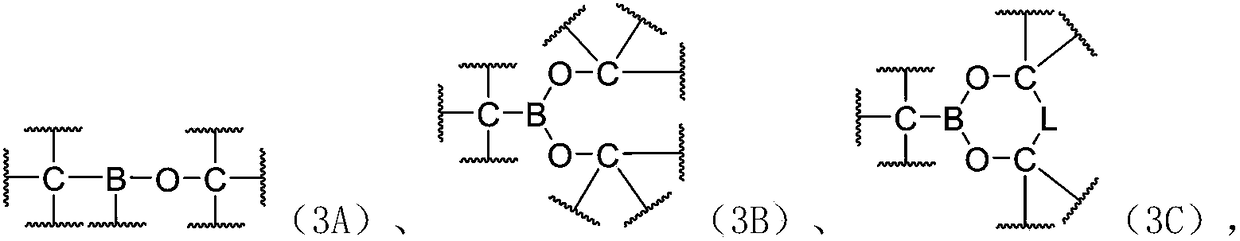

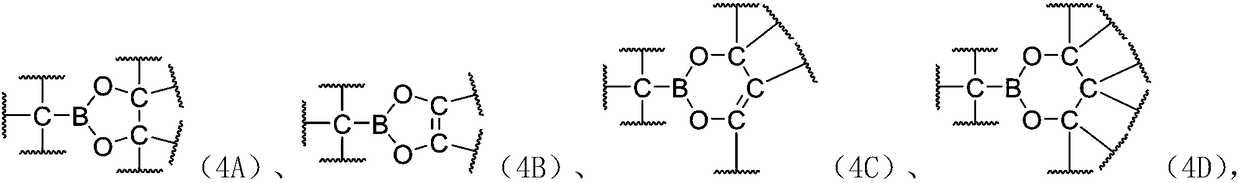

preparation example Construction

[0232] In the preparation process of hybrid dynamic polymers, after the compounds used as raw materials participate in the reaction with each other, the raw material components can be polymerized with boron-containing dynamic covalent bonds or ordinary covalent bonds as link points to obtain higher molecular weight Hybrid Dynamic Polymers. The composition selection and formula ratio of various raw materials used in the preparation of hybrid dynamic polymers can be flexibly controlled, but reasonable design and combination should be carried out according to the properties of the target material, the structure of the selected compound, the number of reactive groups contained, and the molecular weight . The various raw material components added should ensure that the molar equivalent ratio of the functional groups and / or other reactive groups in the reactant system is in an appropriate range. The functional groups contained in the raw material components can be fully reacted or ...

Embodiment 1

[0290] Dissolve 1 molar equivalent of polyethylene glycol (average molecular weight about 2000 Da) terminated by alkenyl groups at both ends and 2 molar equivalents of 3-mercapto-1,2-propanediol in dimethylformamide (DMF), at 0.1 molar equivalent In the presence of photocatalyst benzoin dimethyl ether (BDK), react at room temperature under ultraviolet light to obtain polyethylene glycol terminated with diol.

[0291] Under the protection of nitrogen, disperse 1 molar equivalent of 2-formylphenylboronic acid and anhydrous magnesium sulfate in anhydrous methanol, drop into a methanol solution containing 4 molar equivalents of ethylenediamine at 0 ° C, stir for 30 minutes, and then rise to Stirring was continued at room temperature for 3 hours. The temperature of the reaction solution was lowered to 0°C again, 3 molar equivalents of sodium borohydride was added, and then raised to room temperature to continue stirring for 1 hour. Concentrate the reaction solution, add deionized ...

Embodiment 2

[0295] 2 molar equivalents of compound 2-aminomethylphenylboronic acid and 1 molar equivalent of 1,6-hexamethylene diisocyanate were fully reacted in dichloromethane to obtain compound 2a.

[0296] Dissolve 3 molar equivalents of compound 2a and 2 molar equivalents of boric acid in toluene, slowly add tetrahydrofuran solvent containing 6 molar equivalents of tetraethylene glycol, and react under reflux with water separation to obtain the corresponding hybrid dynamic polymer.

[0297] The hybrid dynamic polymer has a "shear thickening" effect and can be used for shock absorption and shock resistance.

[0298]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com