Fitting large field of view optical pod structure and working method based on flat glass

A large field of view and pod technology, which is applied to the structure and work field of large field of view optical pods based on flat glass fitting, and can solve problems such as the limitation of the forward field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

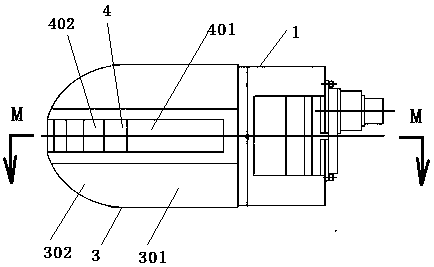

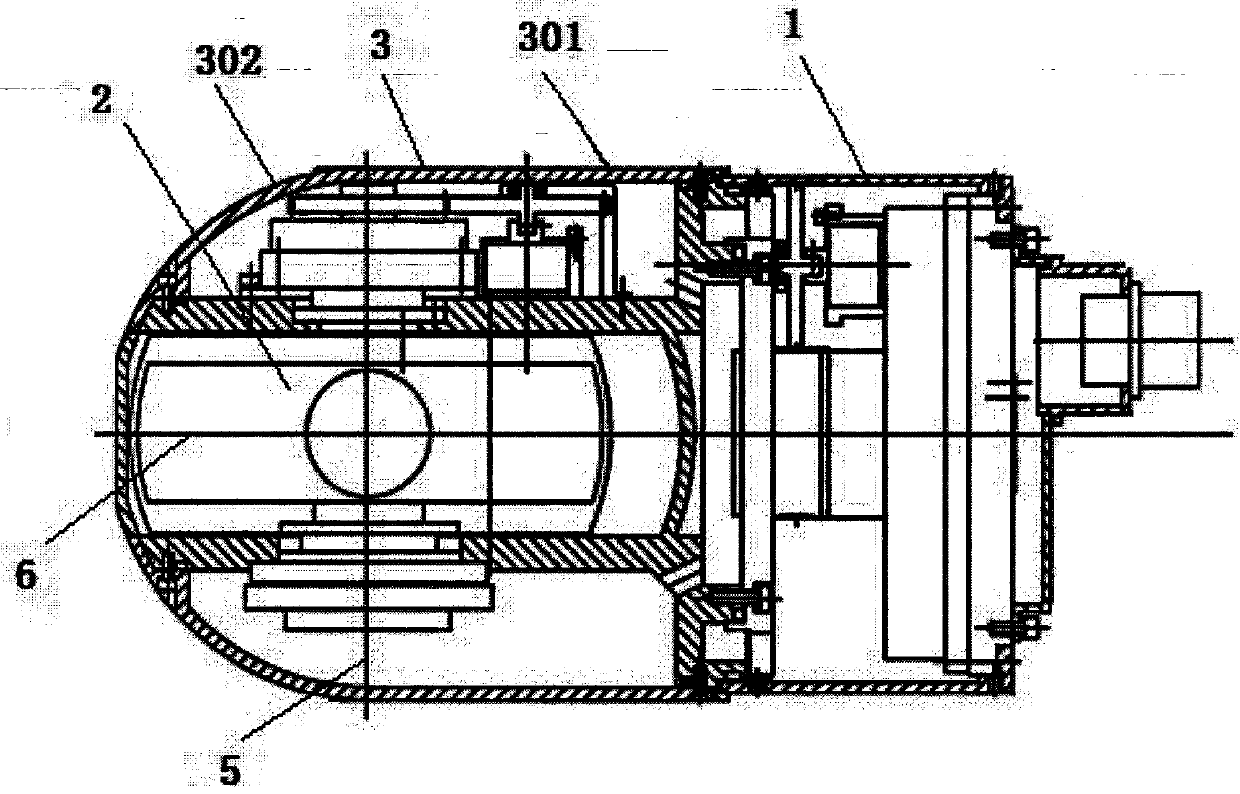

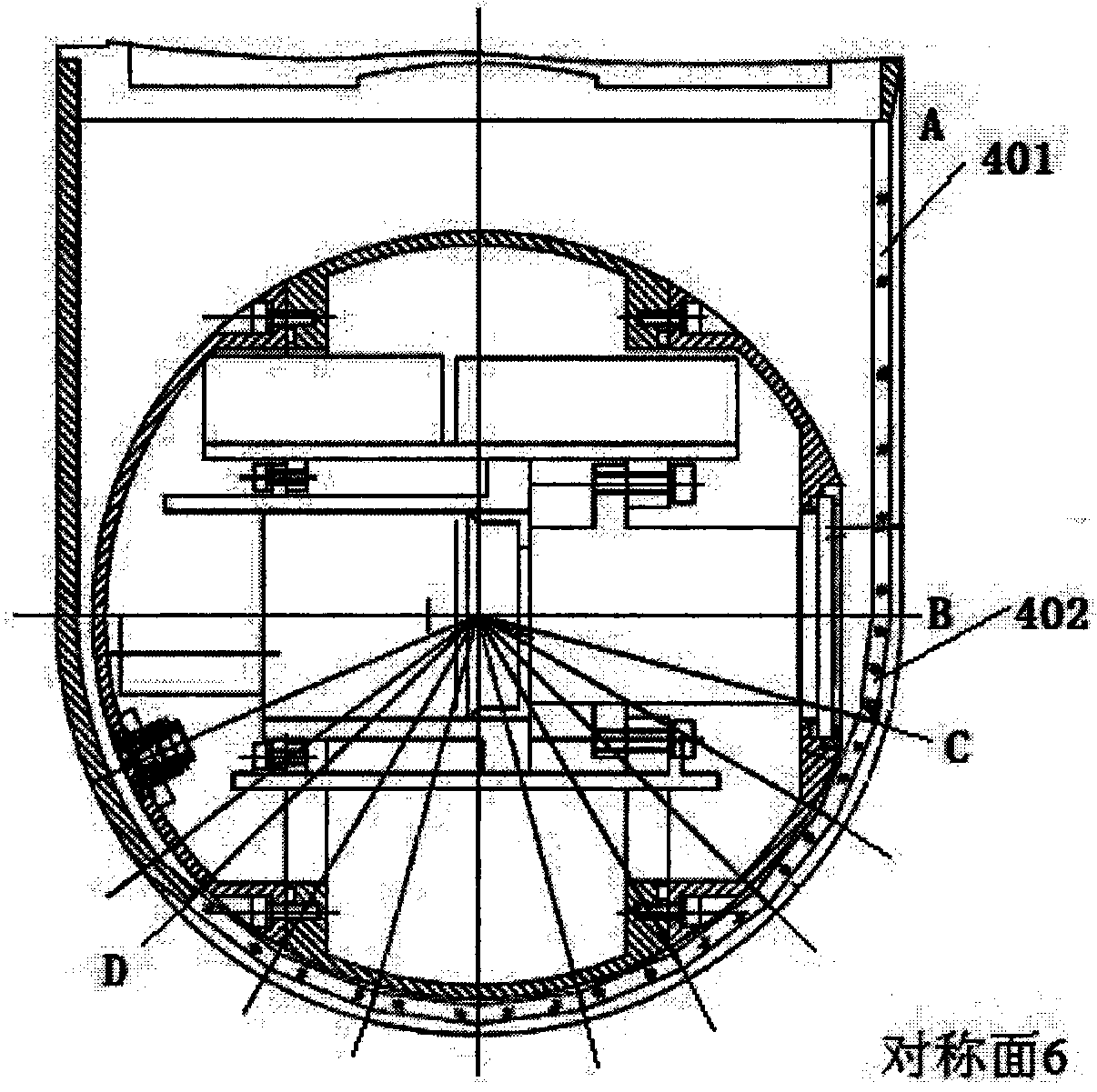

[0021] The present invention is based on the planar glass fitting large field of view optical pod structure, which includes a pod 1 and an optical camera device 2 inside the pod. The strip-shaped visible window 4 , the lens end 5 of the optical camera device 2 is facing the narrow strip-shaped visible window 4 . When the optical imaging device of the present invention moves in pitch, the movement of the optical axis forms a strip, and when the azimuth rotates, the virtual strip formed by the pitch movement moves synchronously with the lens and is relatively static. Theoretically, it can The optical rectification effect is realized by using such a narrow strip protection method.

[0022] Further, in order to design rationally, the end of the pod includes a cylindrical section 301 and a hemispherical section 302, and the partial sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com