Fiberglass/PP composite fiber cloth assisting resin transfer molding (RTM) process method and molding mold

A technology of composite fibers and process methods, applied in the field of molding process methods and molding molds, can solve problems such as low product qualification rate, uneven resin flow, and large environmental pollution, and achieve reduced processing costs, uniform resin flow, and environmental protection. The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

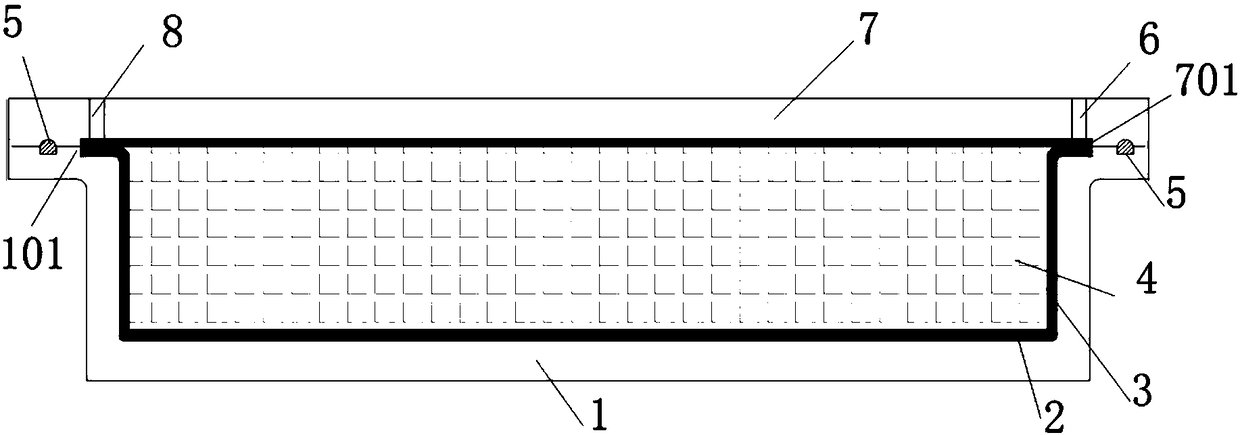

[0026] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0027] figure 1 It is an overall schematic diagram of the present invention, such as figure 1 As shown, a kind of process method of glass fiber / PP composite fiber cloth assisted RTM forming provided by the present invention, the process method of described glass fiber / PP composite fiber cloth assisted RTM forming comprises the following steps:

[0028] Step (1), first clean the foreign matter on the surface of the mold cavity, the mold cavity includes the upper mold 7 and the lower mold 1, and then use a dust-free cloth to evenly wipe the composite material release agent on the mold cavity of the lower mold 1 and the upper mold 7 The surface of the first layer of fiber cloth 2 needs to be placed in the groove to ensure that each position is evenly covered by the release agent;

[0029]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com