Cylindrical graphite machining method and machining device

A processing device, a cylindrical technology, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems that graphite electrodes with special structures cannot be produced, and achieve the effect of low cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

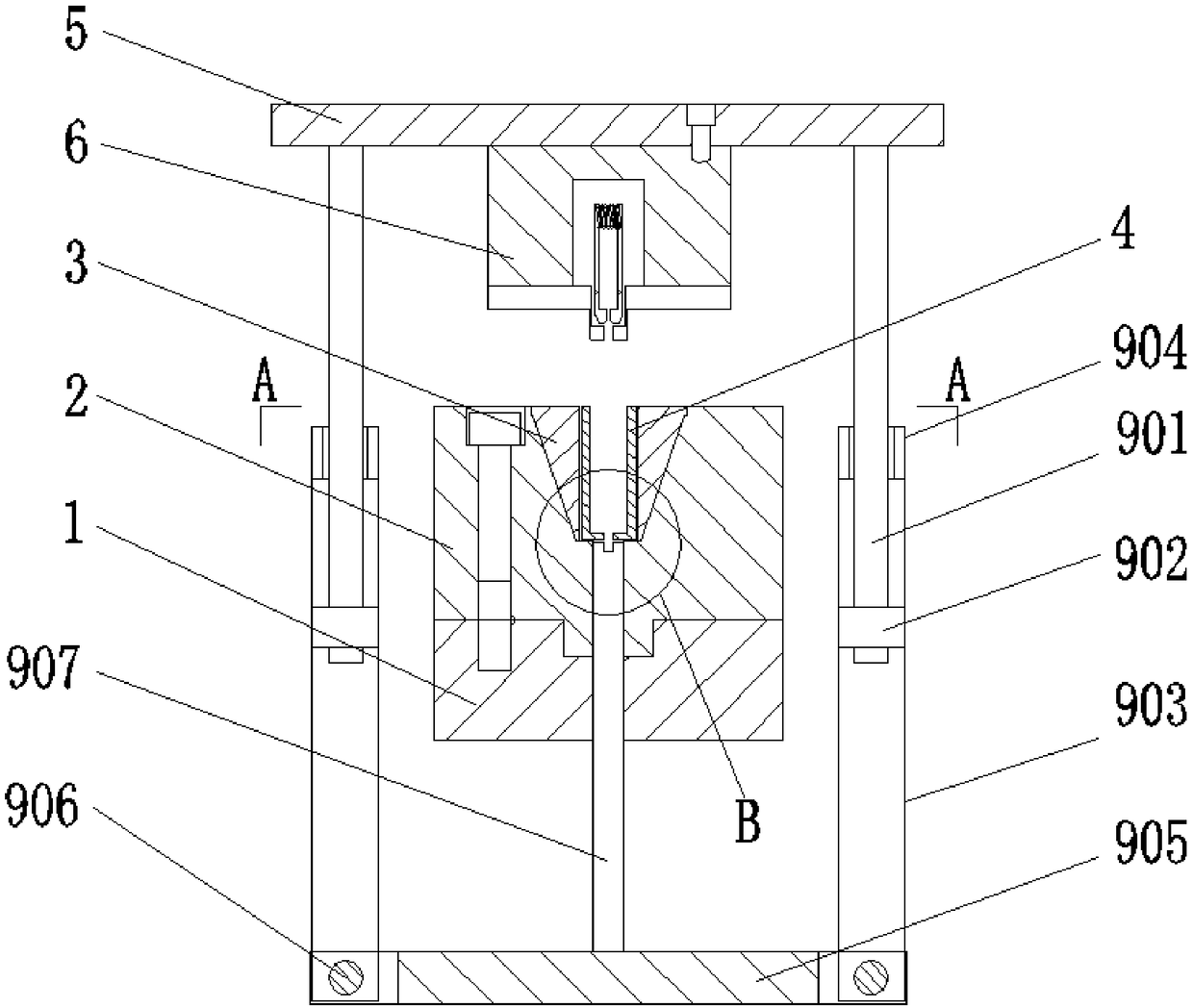

[0038] Specific implementation mode 1, such as figure 1 As shown, a processing device for cylindrical graphite according to the present invention includes a base 1, a die holder 2, a die 3, a die cover 4, a connecting plate 5, a punch assembly 6, an ejection mechanism and Ring resistance wire 9,

[0039] The ejector mechanism includes a pull rod 901, a slide block 902, a slideway 903, a limit block 904, a supporting plate 905 and a push rod 907,

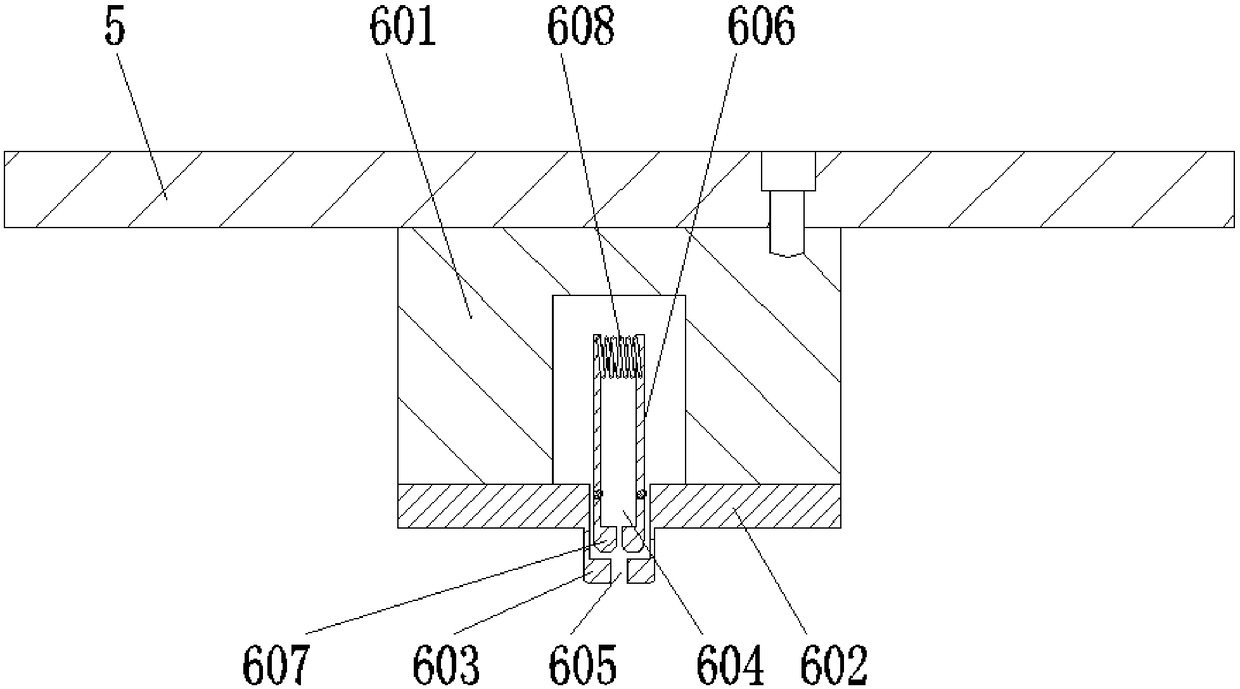

[0040] The punch assembly 6 includes a punch holder 601, a punch 602, a boss 603, a first mounting groove 604, a first through hole 605, a pole 606, a collet 607 and a compression spring 608;

[0041] The base 1 is fixed on the press console, the base 1 is fixed with a die holder 2, the upper end surface of the die holder 2 is inlaid with a die 3, and the die holder 2 and the die 3 are connected by a screw , the die 3 is rounded truncated and has a through hole in the center, the die cover 4 is installed in the through hole, and th...

specific Embodiment approach 2

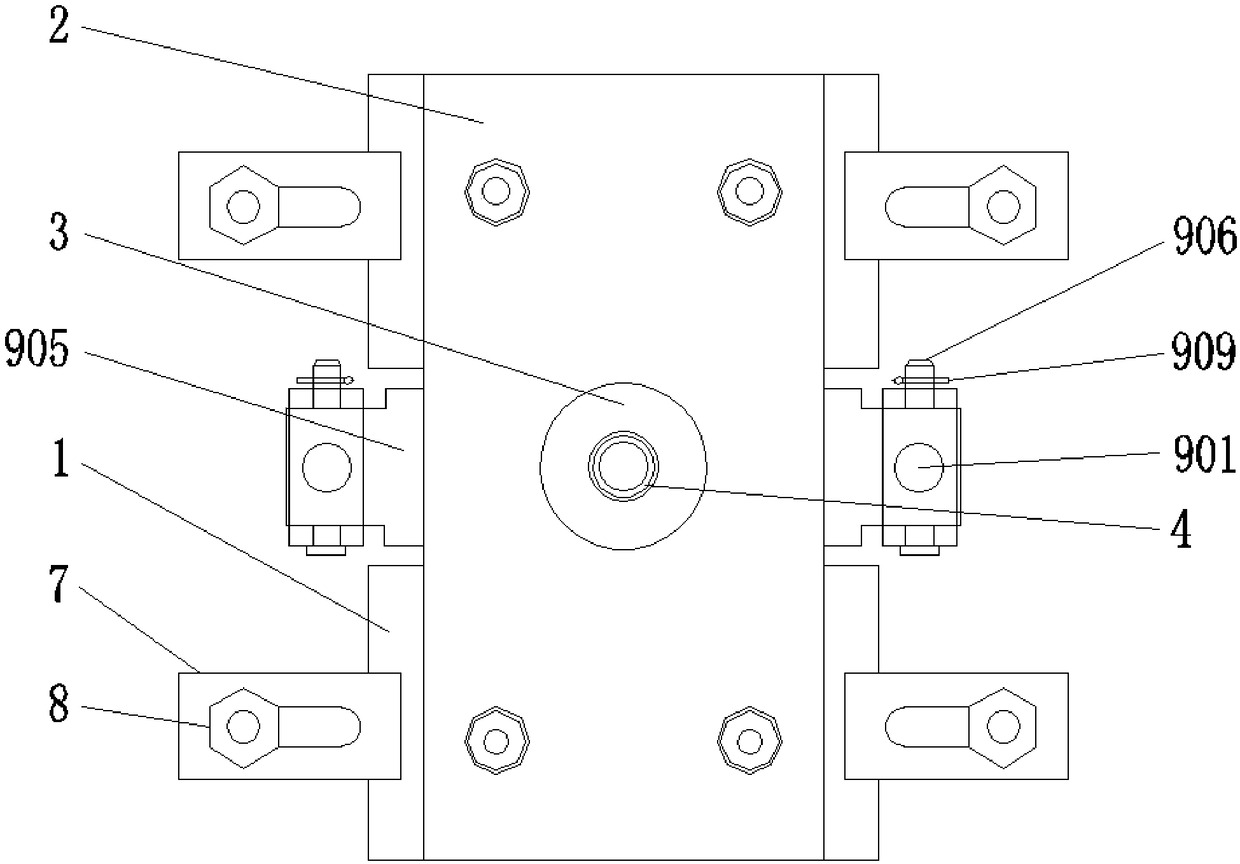

[0043]Specific implementation mode 2, such as figure 2 As shown, the difference between this embodiment and the specific embodiment 1 is that the base 1 is fixed on the press console through the pressing plate 7 and bolts 8 installed on the press console.

specific Embodiment approach 3

[0044] Specific implementation mode 3: as figure 1 and figure 2 As shown, the difference between this embodiment and specific embodiments 1 and 2 is that the lower end of the slideway 903 is connected to the supporting plate 905 through a pin 906 , and a snap spring 909 is installed on the pin 906 .

[0045] A kind of processing method of the processing device of cylindrical graphite, is characterized in that, comprises the following steps:

[0046] Step 1: Prepare graphite core; mix natural graphite powder and needle coke powder, add coal tar pitch and ferric oxide powder, heat and mix thoroughly;

[0047] Step 2: Knead the paste obtained in Step 1, and use a press to press the material into a cylindrical shape, so that it can just pass through the second through hole 401 and be placed in the second installation groove 910. The top of the cylinder and the die sleeve 4 is flush with the top surface;

[0048] Step 3: Weigh 80 parts of graphite powder, 15 parts of high wear-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com