Self-priming pump

A self-priming pump and pump body technology, applied in the direction of pump, pump control, driving pump, etc., can solve the problems of poor steam-water separation effect, damage to vacuum pump, inconvenience of changing the direction of input and output of self-priming pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

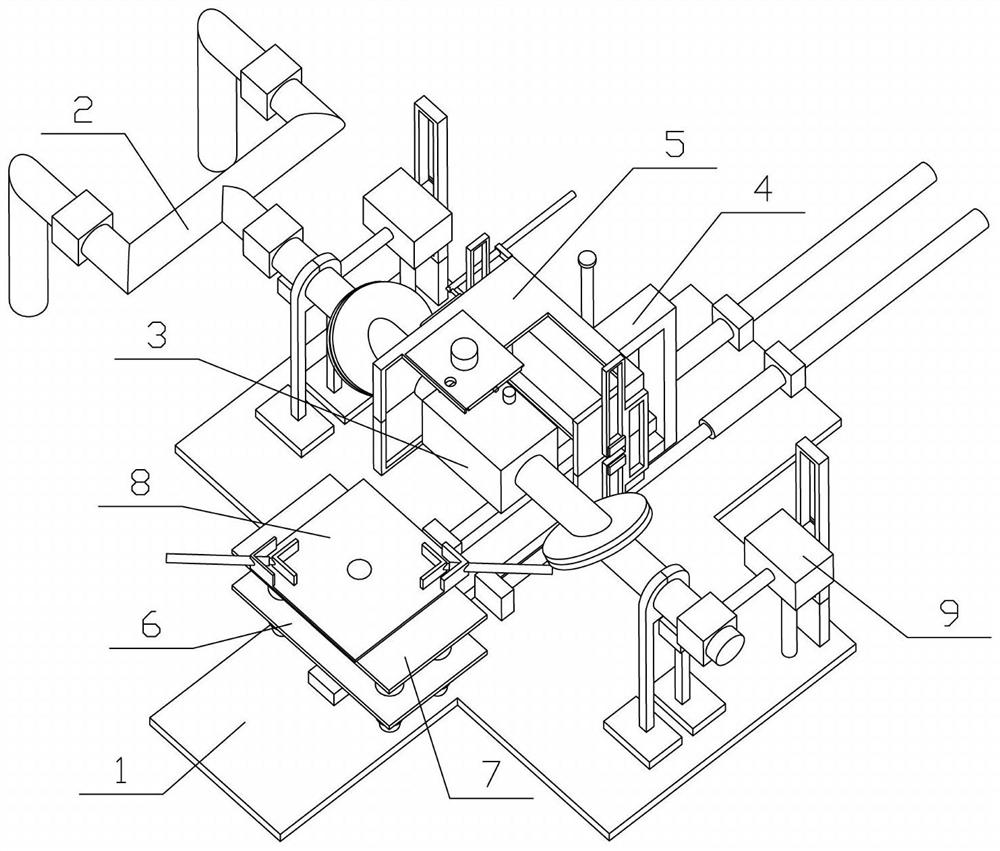

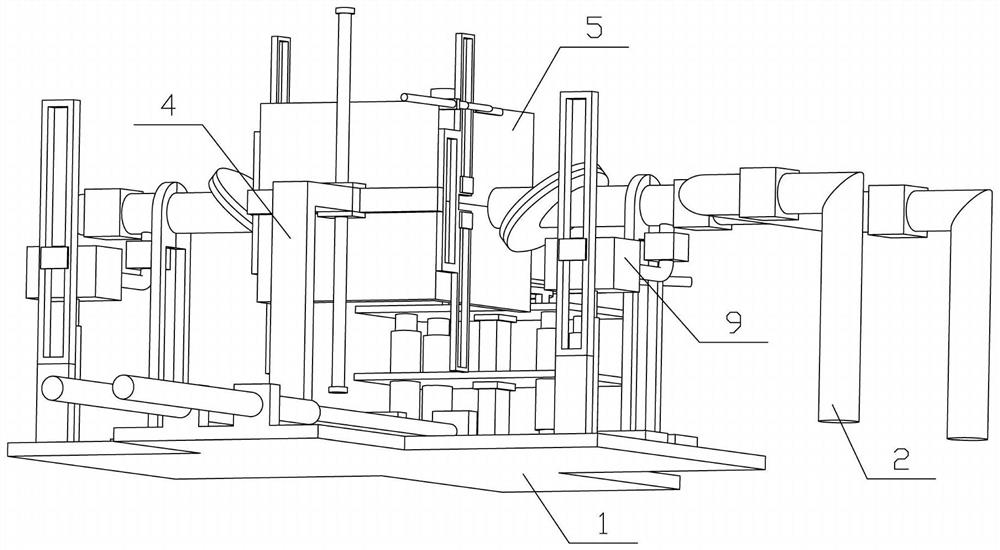

[0032] Combine below Figure 1-11 Describe this embodiment, the present invention relates to the technical field of self-priming pumps, more specifically self-priming pumps, including a chassis 1, a conveying device 2, a self-priming pump 3, a lifting device 4, a cooling device 5, a lifting device 6, and a rotating device 7 , clamping device 8 and liquid storage device 9, the present invention is convenient to change the input and output direction of the self-priming pump.

[0033]The bottom frame 1 is fixedly connected with a conveying device 2, the conveying device 2 communicates with the self-priming pump 3, the lifting device 4 is slidably connected with the bottom frame 1, the cooling device 5 is slidably connected with the lifting device 4, and the cooling device 5 is connected with the conveying device 2 Cooperate, the lifting device 6 is slidably connected on the chassis 1, the lifting device 6 is fixedly connected with the lifting device 4, the rotating device 7 is fi...

specific Embodiment approach 2

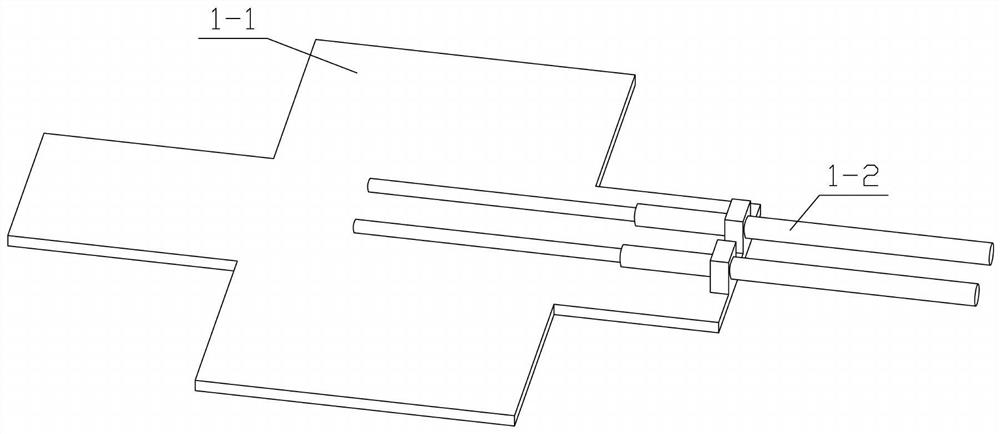

[0035] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the chassis 1 includes a bottom plate 1-1 and an electric push rod I1-2, and two electric push rods I1-2 are fixedly connected to the bottom plate 1-1 ; By starting the telescopic movement of the electric push rod I1-2, the lifting device 4 and the lifting device 6 can be moved along the front and rear directions, and then the cooling device 5 and the clamping device 8 can be driven to move along the front and rear directions.

specific Embodiment approach 3

[0037] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the delivery device 2 includes a branch pipe 2-1, a main pipe 2-2, a bracket 2-3, an on-off valve I2-4 and an on-off valve II2-5, There are two branch pipes 2-1, the two branch pipes 2-1 and the main pipe 2-2 are connected by a tee, the support 2-3 is composed of two and a half supports, and the support 2-3 is provided with two, two supports The lower part of 2-3 is fixedly connected with the bottom plate 1-1, the two brackets 2-3 are installed on the main pipe 2-2, the two branch pipes 2-1 are equipped with on-off valve I2-4, the main pipe 2-2 On-off valve II 2-5 is installed at the left and right ends, two sets of flanges are set on the main pipe 2-2, each set of flanges are fixed by studs; on-off valve I 2-4 has a control valve 2-1 for liquid circulation or cut-off function, the on-off valve II 2-5 plays the function of facilitating the disassembly and as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com