Rotary-wing micro-porous filter

A technology of rotary wing and filter, which is applied in the direction of filtration separation, membrane filter, filtration treatment, etc. It can solve the problems of low resistance to pollutant impact load, low filtration accuracy, and failure to work normally, achieving long service life, The effect of high filtration precision and high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

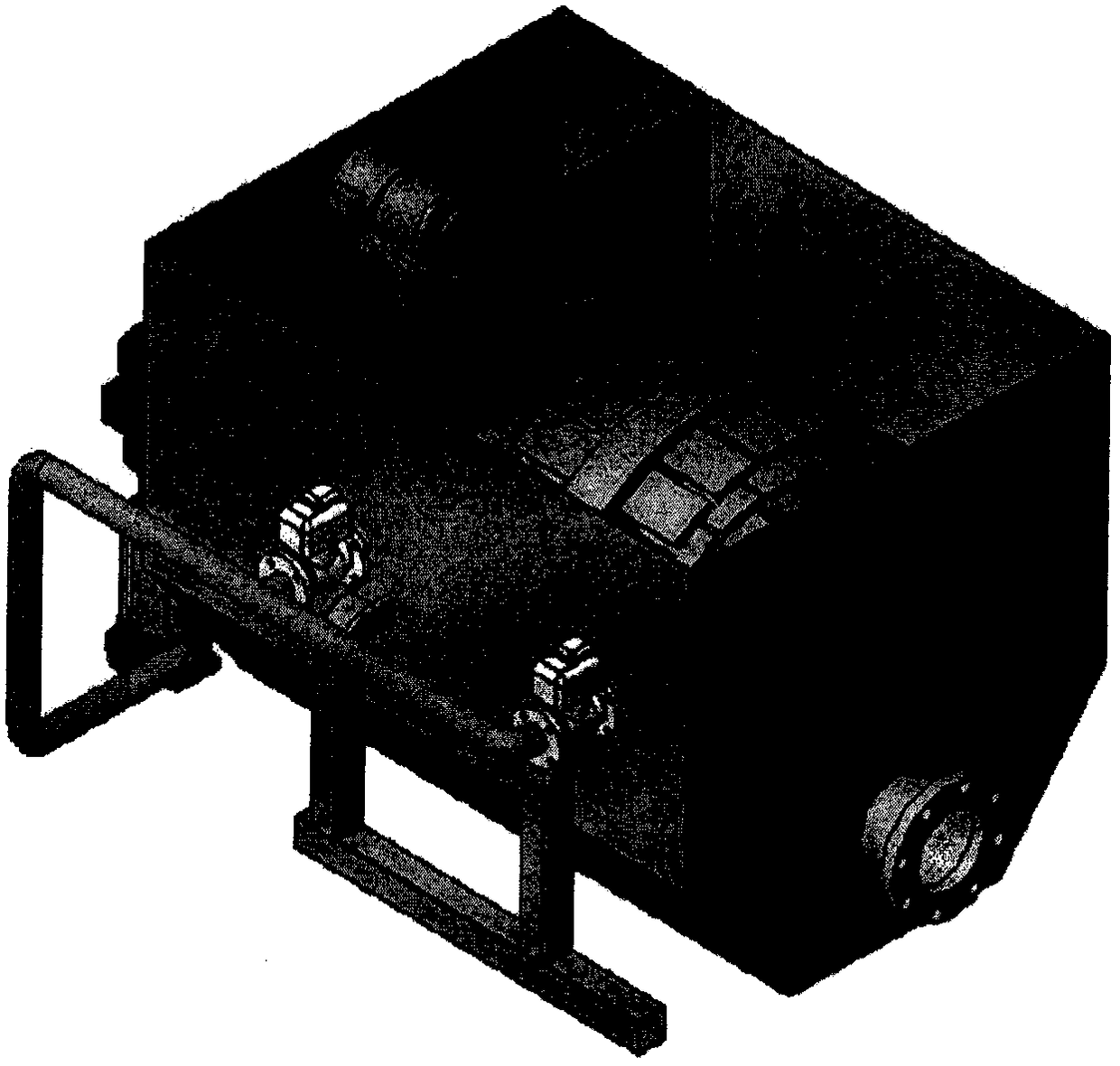

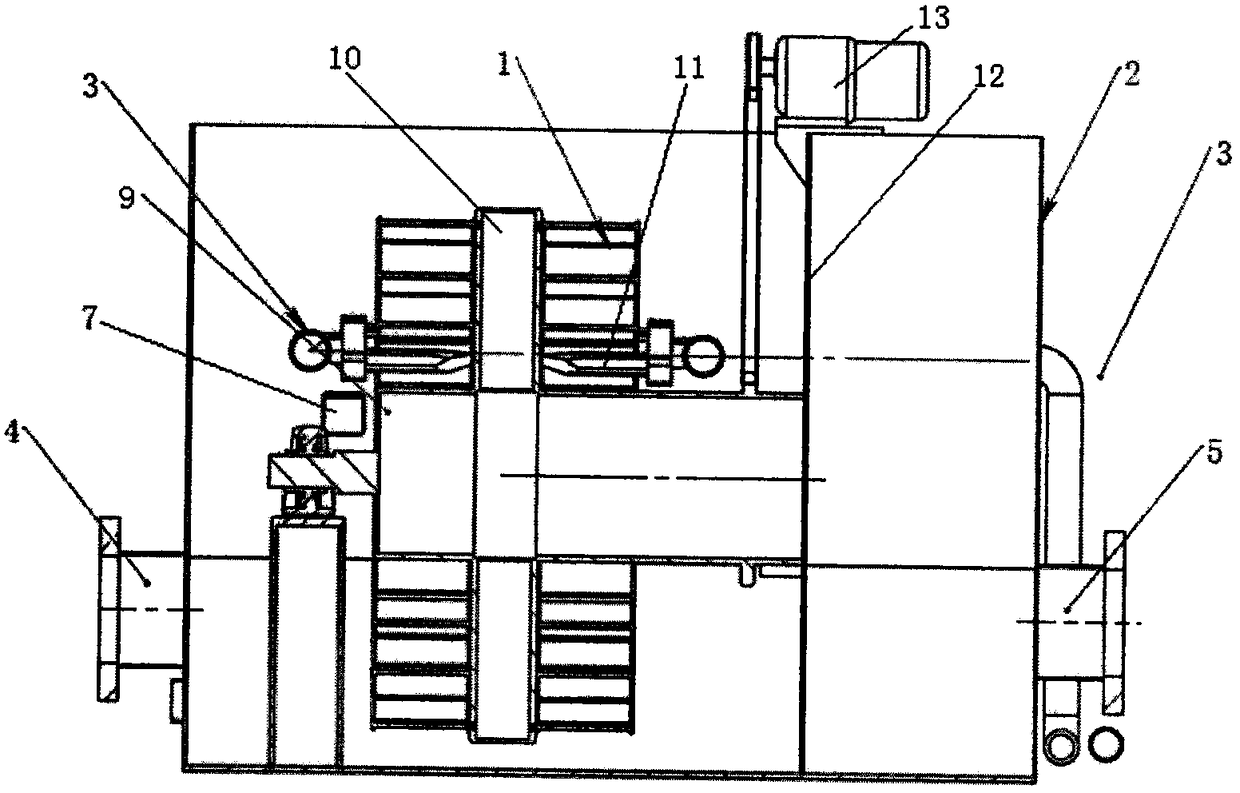

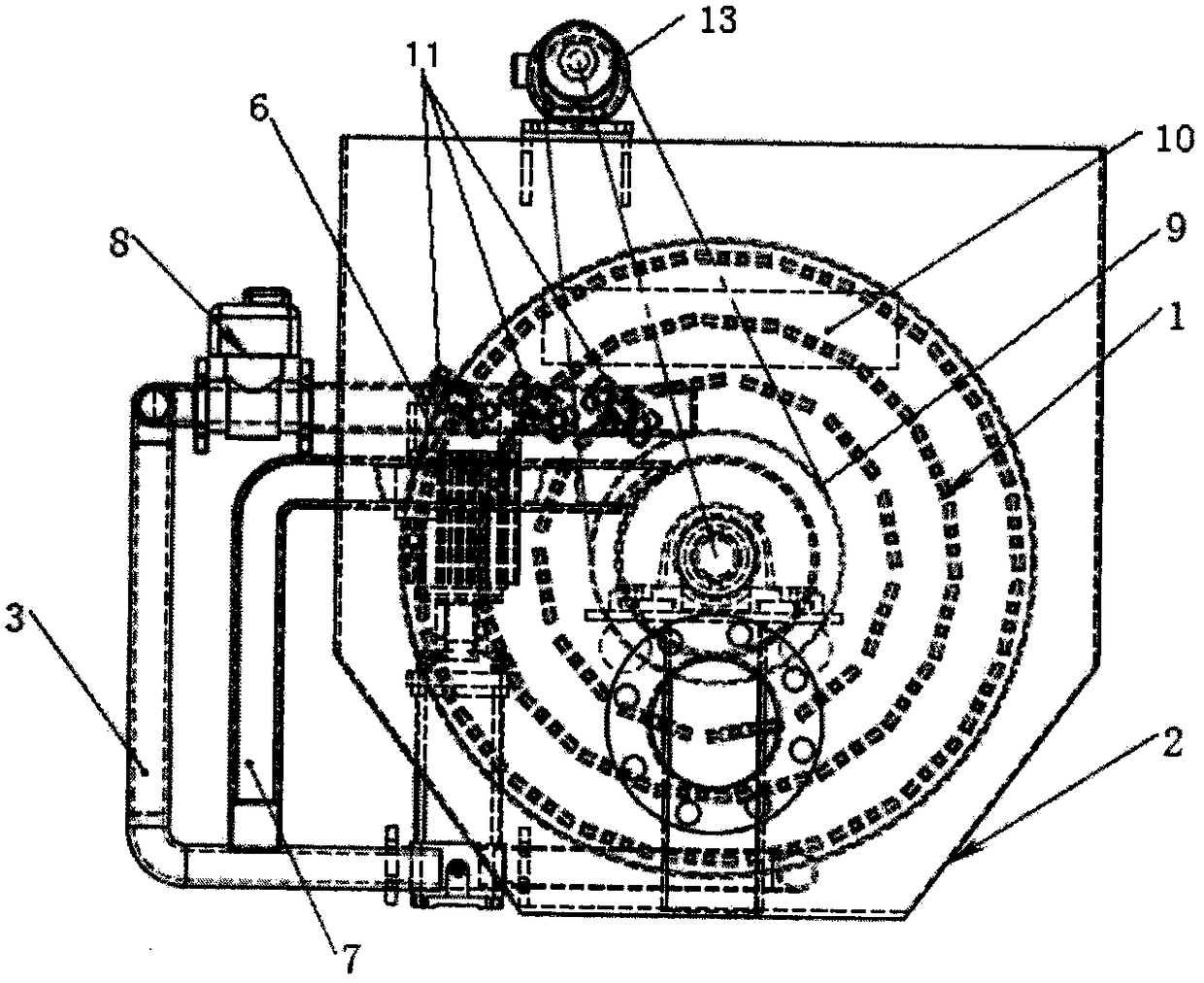

[0013] The rotary wing microporous filter machine proposed by the present invention for water or air filtration, such as figure 1 , figure 2 and image 3 As shown, it includes filter flap 1, pool body 2, backwash pipeline 3, water inlet 4, water outlet 5, backwash water pump 6, sewage pipeline 7, electric valve 8, center drum 9, circular turntable 10 , backwashing nozzle 11 , outlet weir 12 , drive system 13 . There is a water inlet 4 at one end of the pool body 2 of the rotary wing microporous filter, and a water outlet 5 at the other end; the central drum 9 is installed in the pool body 2, and one end is supported by a bearing, and the other end is supported by a chain sprocket ; Several hollow circular turntables 10 are installed vertically on the central drum 9, and several filter wings 1 take the central drum 9 as the center of a circle and are fixed on both sides of the circular turntable 10 in a ring shape. , keep a reasonable gap between each ring of filter wings 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com