Low-temperature-resisting storage battery electrolyte and preparation method thereof

A storage battery and low-temperature-resistant technology, applied in lead-acid batteries, acid electrolytes, aqueous electrolytes, etc., can solve the problems of poor low-temperature performance and short service life of batteries, prevent crystallization, avoid sulfation, and improve low-temperature performance and life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

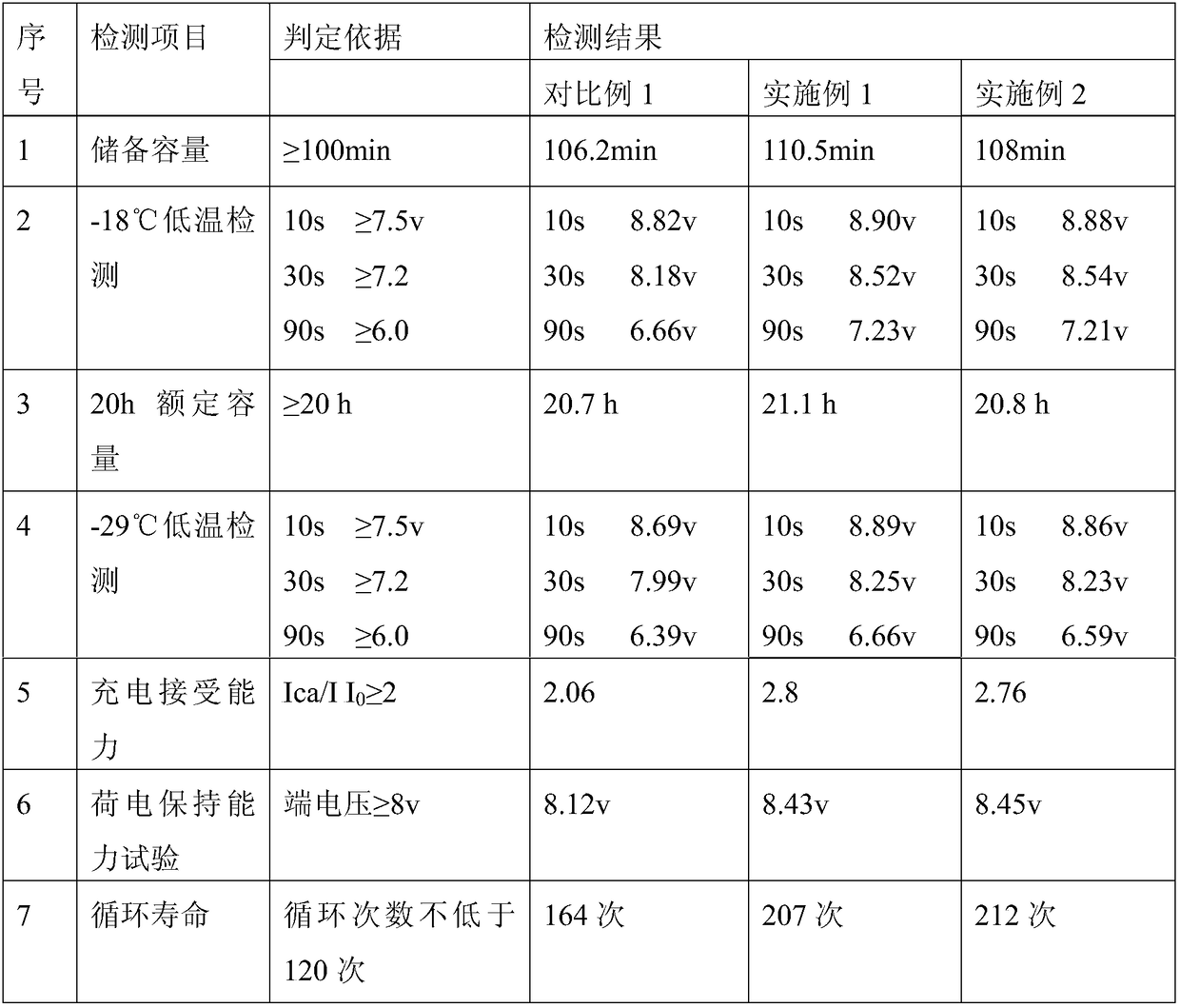

Examples

Embodiment 1

[0042] 1. Battery electrolyte formula: pure water (conductivity less than 0.3μS / cm) 63kg, sulfuric acid (analytical pure) 32kg, tannin (for battery) 0.3kg, magnesium lignosulfonate 0.2kg, lithium sulfite 0.08kg, Stannous sulfate 0.06kg, polyepoxysuccinic acid 4kg, hydroxymethylcellulose 0.7kg.

[0043] 2. Preparation method

[0044] (1) Heat 6.4kg of formula water, keep it at 80°C, then add tannin, stir at 400r / min for 30 minutes to ensure that the tannin is evenly mixed in the water, lower the temperature of the solution to 60°C, and then add lignosulfonic acid Magnesium was stirred at a speed of 200r / min for 20 minutes to ensure that the magnesium lignosulfonate was evenly mixed in the solution, and left to stand at room temperature for use.

[0045] (2) Heat 20% of the formula water, keep it at 50°C, then add polyepoxysuccinic acid, stir at a speed of 200r / min for 20 minutes, ensure that the polyepoxysuccinic acid is evenly mixed in the solution, keep the temperature and t...

Embodiment 2

[0048] 1. Battery electrolyte formula: pure water (conductivity less than 0.3μS / cm) 66kg, sulfuric acid (analytical pure) 34kg, tannin (for battery) 0.4kg, magnesium lignosulfonate 0.15kg, lithium sulfite 0.07kg, Stannous sulfate 0.08kg, polyepoxysuccinic acid 6kg, hydroxymethylcellulose 0.2kg.

[0049] 2. Preparation method

[0050] (1) Heat 6.4kg of formula water, keep it at 90°C, then add tannin, stir at a speed of 300r / min for 20 minutes to ensure that the tannin is evenly mixed in the water, lower the temperature of the solution to 70°C, and then add lignosulfonic acid Magnesium was stirred at a speed of 100 r / min for 10 minutes to ensure that the magnesium lignosulfonate was evenly mixed in the solution, and left to stand at room temperature for use.

[0051] (2) Heat 20% of the formula water, keep it at 60°C, then add polyepoxysuccinic acid, stir at a speed of 100r / min for 10 minutes, ensure that the polyepoxysuccinic acid is evenly mixed in the solution, keep the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com