Energy-saving-type heating device and work method thereof

A heating device and energy-saving technology, applied in the field of machinery, can solve the problems of reducing water flow, reducing the inner diameter of iron pipes, wasting energy, etc., and achieving the effects of convenient removal and cleaning, reducing water waste, and improving heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

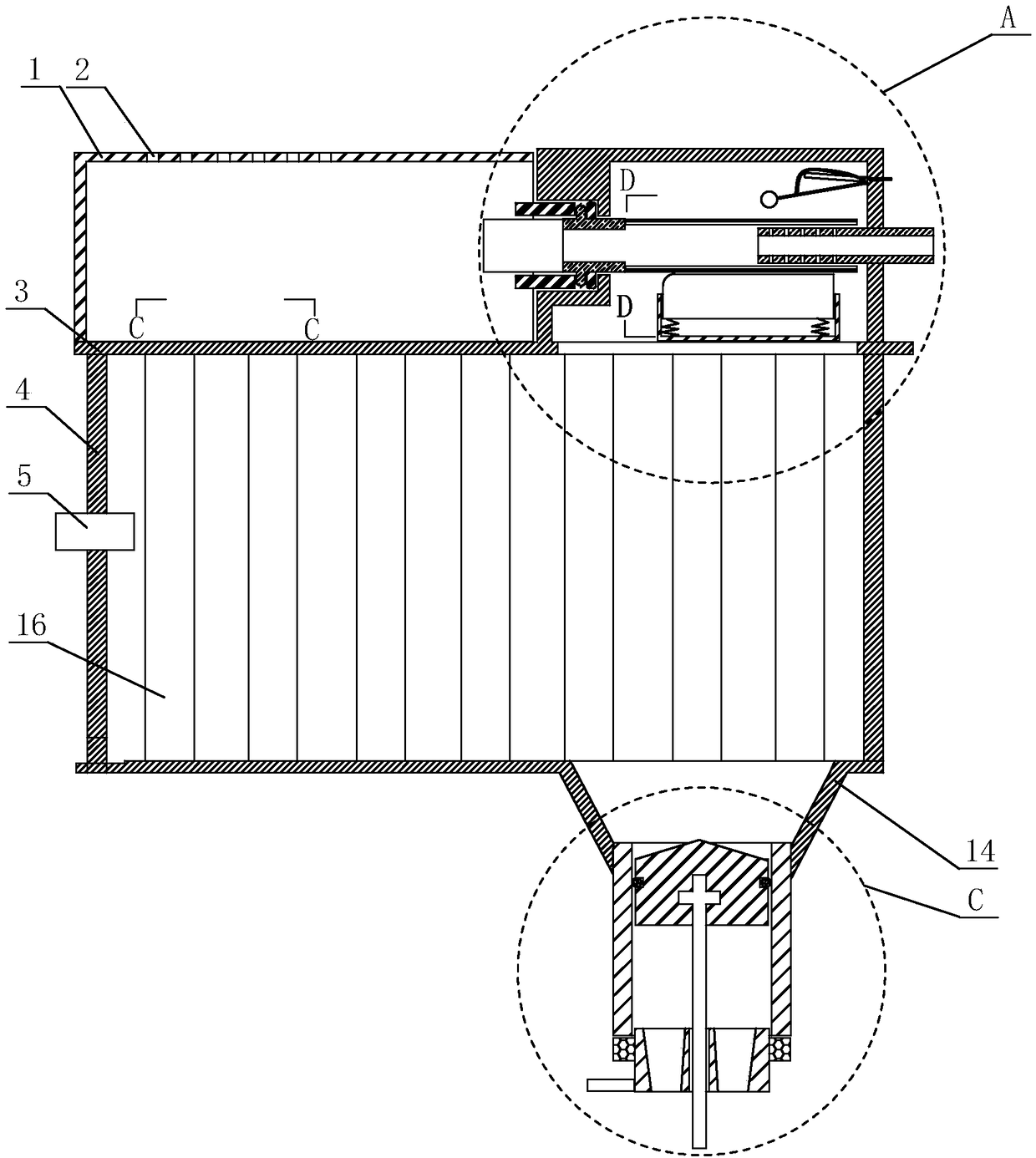

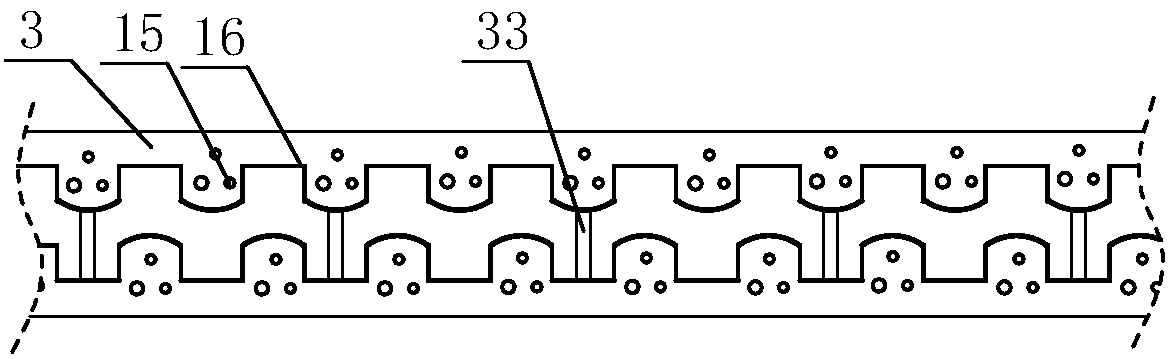

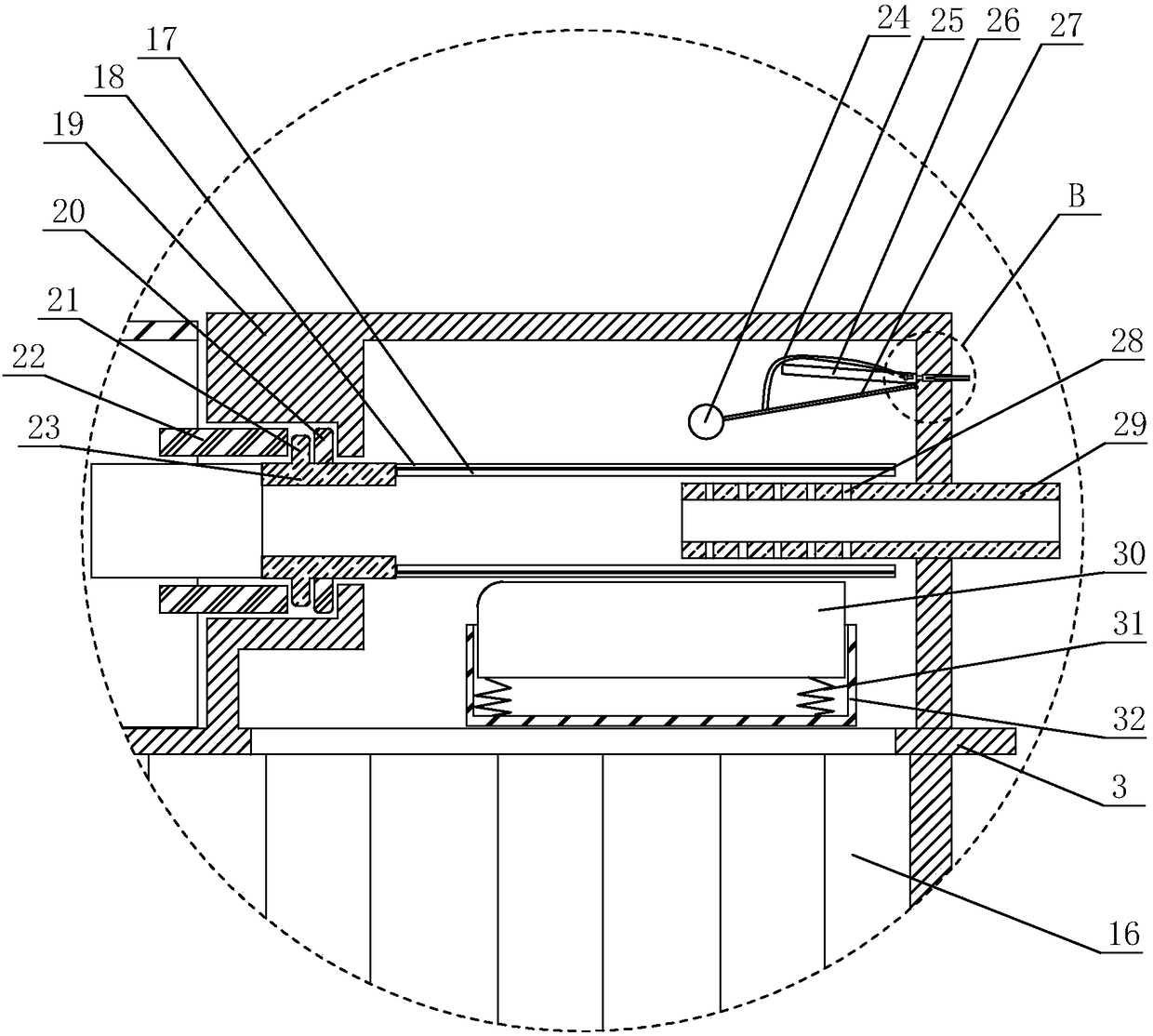

[0028] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0029] Such as Figure 1-Figure 9 As shown, the energy-saving heating device of the present invention includes two heat sinks 16 with the same specification, the two sides of the heat sink 16 are fixedly connected to two connecting plates 4, the upper and lower sides of the heat sink 16 are fixedly connected to the sealing plate 3, and the sealing plate 3. The heat sink 16 and the connecting plate 4 form a closed space. The connecting plate 4 on the left is provided with a water inlet pipe. A small stepped hole, the inner wall of the stepped hole is provided with threads, the stepped hole is matched with a threaded cylinder 22, the outer wall of the threaded cylinder 22 is threaded, the threaded cylinder 22 is matched with the portion facing the stepped hole, and the threaded cylinder 22 is provided with a filter cylinder 23 , the filter cartridge 23 side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com