Single-circulation two-stage LNG cold energy power generation and ice making method and system

A single cycle, cold energy technology, applied in the direction of ice making, ice making, fluid circulation arrangement, etc., can solve the problems of poor economic benefits, high investment costs, low single-stage utilization efficiency, etc., to simplify the process and equipment composition, reduce Effects of investment and floor area, saving heat and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The LNG components (mole fraction) provided by the LNG receiving station are: methane 99.78%, ethane 0.1%, nitrogen 0.12%; the flow rate is 200t / h, and the organic working fluid used in the Rankine cycle power generation system is ethane.

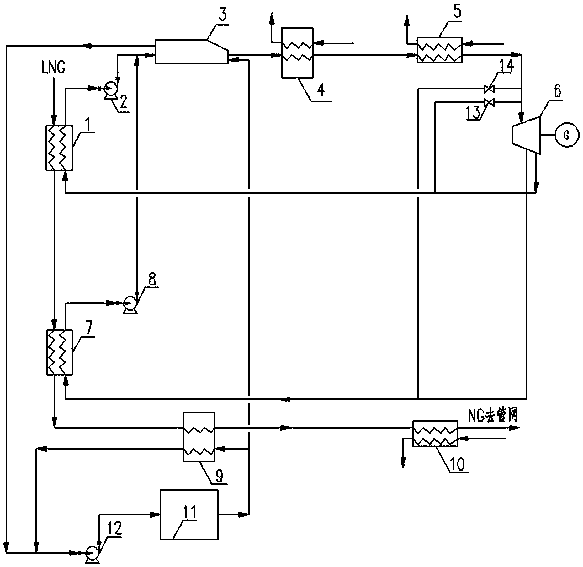

[0035] Such as figure 1 As shown, a single-cycle two-stage LNG cold energy power generation and ice-making method: LNG at -155 ° C is pressurized to 9.8 MPa by a booster pump, and the first condenser 1 and the turbine power generation unit 6 come out Low-pressure organic working medium steam heat exchange, recycling LNG cold energy in the low-temperature section (-155°C ~ -102°C) to obtain low-pressure organic working medium liquid; The working medium steam is heat-exchanged in the second condenser 7, and the LNG temperature cold energy in the medium temperature section (-102°C ~ -47°C) is recovered to obtain medium-pressure organic working medium liquid; after heat exchange with LNG, the low-pressure organic working medium is conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com