Monocrystalline silicon crucible

A monocrystalline silicon and crucible technology, which is applied in the field of semiconductor and solar crystal growth equipment, can solve the problems of poor radial thermal conductivity, high oxygen content of monocrystalline silicon, and large energy consumption, so as to increase volume, improve heat transfer, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

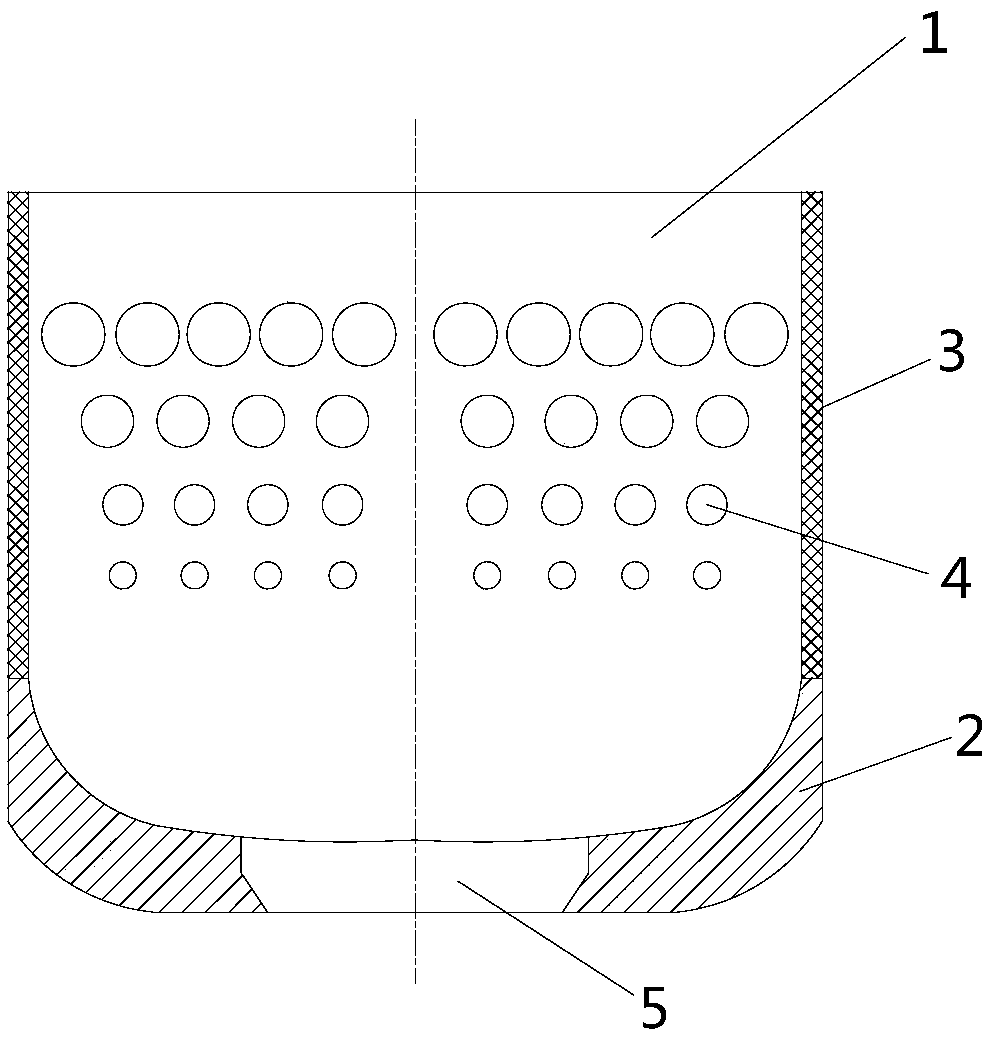

[0044] Such as figure 1 and figure 2 As shown, a Czochralski monocrystalline silicon crucible described in this embodiment includes a crucible part 1 body configured to hold a quartz crucible; the crucible part 1 includes a hole unit 4 arranged on the side wall of the crucible part 1 body , communicates with the inner and outer spaces of the crucible part 1; the proportion of the hole unit 4 in the circumferential direction of the second crucible unit 3 gradually increases from one side to the other side of the bottom of the crucible part 1, because in the process of refining single crystal silicon , through the setting of the hole unit 4 to better control the transfer of heat, control the temperature distribution of the molten liquid up and down, and at the same time save more energy in the process of growing the crystal, by setting the hole on the side wall of the crucible part 1 The unit 4 increases the gas permeability of the crucible part 1. During the heating process, ...

Embodiment 2

[0046] Such as figure 1 and figure 2 As shown, this embodiment is a further limitation of the first embodiment above. A single crystal silicon crucible described in this embodiment, the material of the crucible part 1 is set as a carbon-carbon composite material, due to the particularity of the carbon-carbon composite material , its structure is interwoven distribution, and its heat transfer effect is poor. Therefore, a number of hole units 4 are arranged on its surface to increase the air permeability and light transmittance of the crucible part 1. During the heating process, heat is transferred from the hole units 4 In the hot crucible part 1, the transfer of heat is increased, and the distribution of the hole units 4 is arranged on the side wall of the crucible part 1, which facilitates the convection control inside the crucible part 1 during the heating process, thereby reducing the temperature of the single crystal silicon oxygen content.

[0047] In addition, due to t...

Embodiment 3

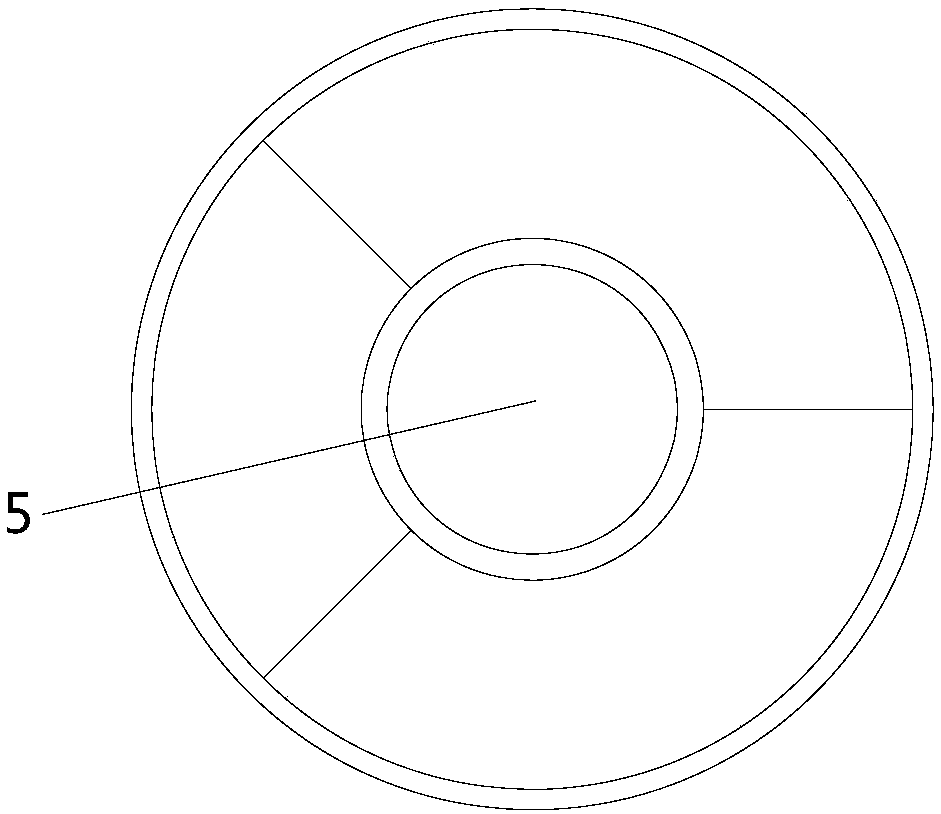

[0049] Such as figure 1 and figure 2 As shown, this embodiment is a further limitation of the first embodiment above. A single crystal silicon crucible described in this embodiment includes a crucible part 1 body configured to hold a quartz crucible; the crucible part 1 includes a first crucible The unit 2 is configured as the bottom of the crucible part 1 and is surrounded by at least two petals. The center of the first crucible unit 2 is provided with a through hole 5; the second crucible unit 3 is connected with the first crucible unit 2 to form a crucible The side wall of the part 1; the hole unit 4 is arranged on the second crucible unit 3 and communicates with the inner and outer spaces of the crucible part 1; the area of the crucible part 1 that contacts the external space through the hole unit 4 is from one side of the bottom of the crucible part 1 to the other gradually increase on one side.

[0050] In the present invention, the crucible is arranged in a two-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com