A kind of silk making device that reduces broken wire

A technology for making and breaking silk, which is applied in the production, transportation and packaging of silk fibers, and the transportation of filamentous materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below.

[0027] Unless otherwise specified, the raw materials used in the present invention can be purchased from the market or commonly used in the field. If not specified, the methods in the following examples are all conventional methods in the field.

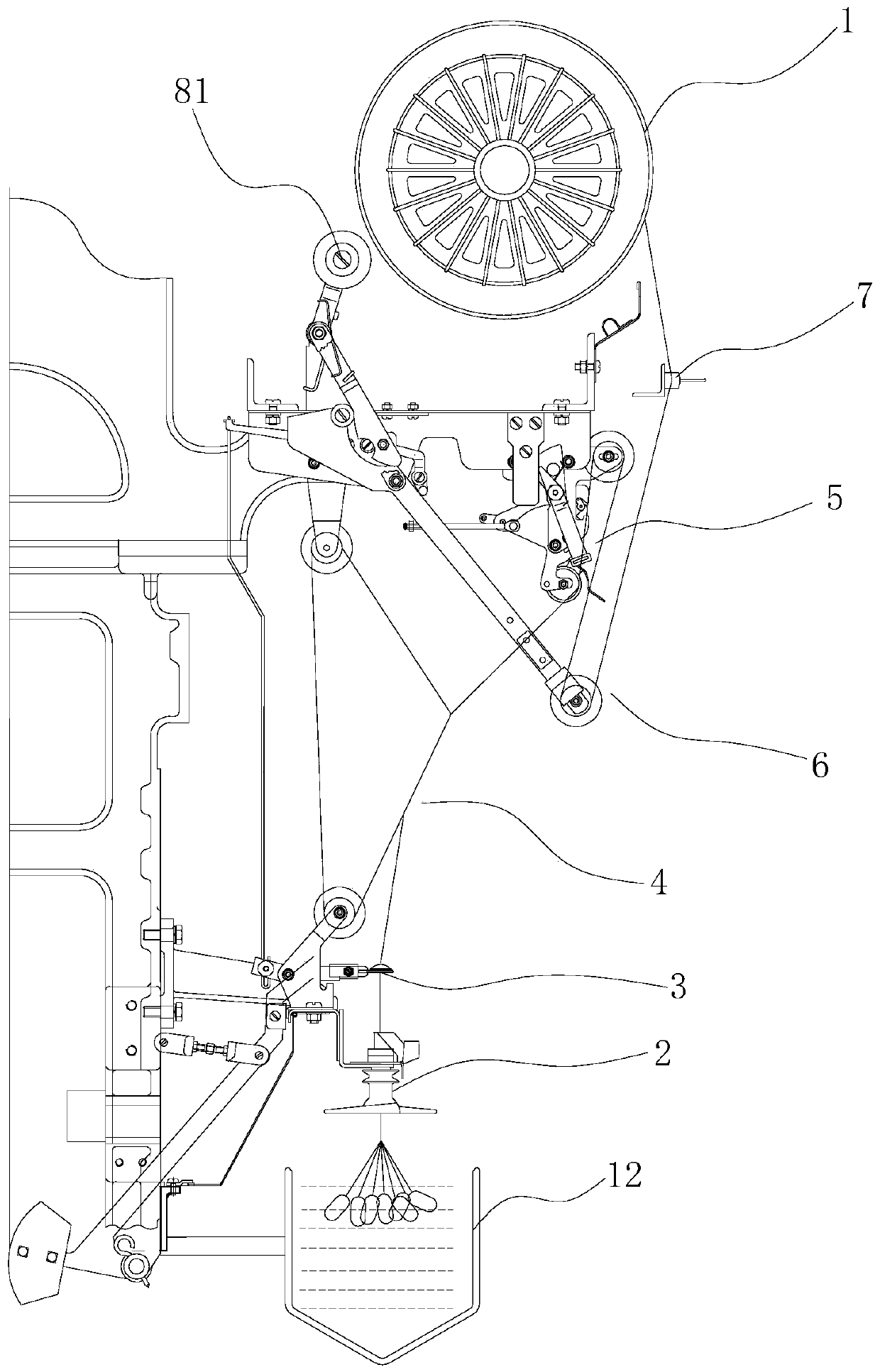

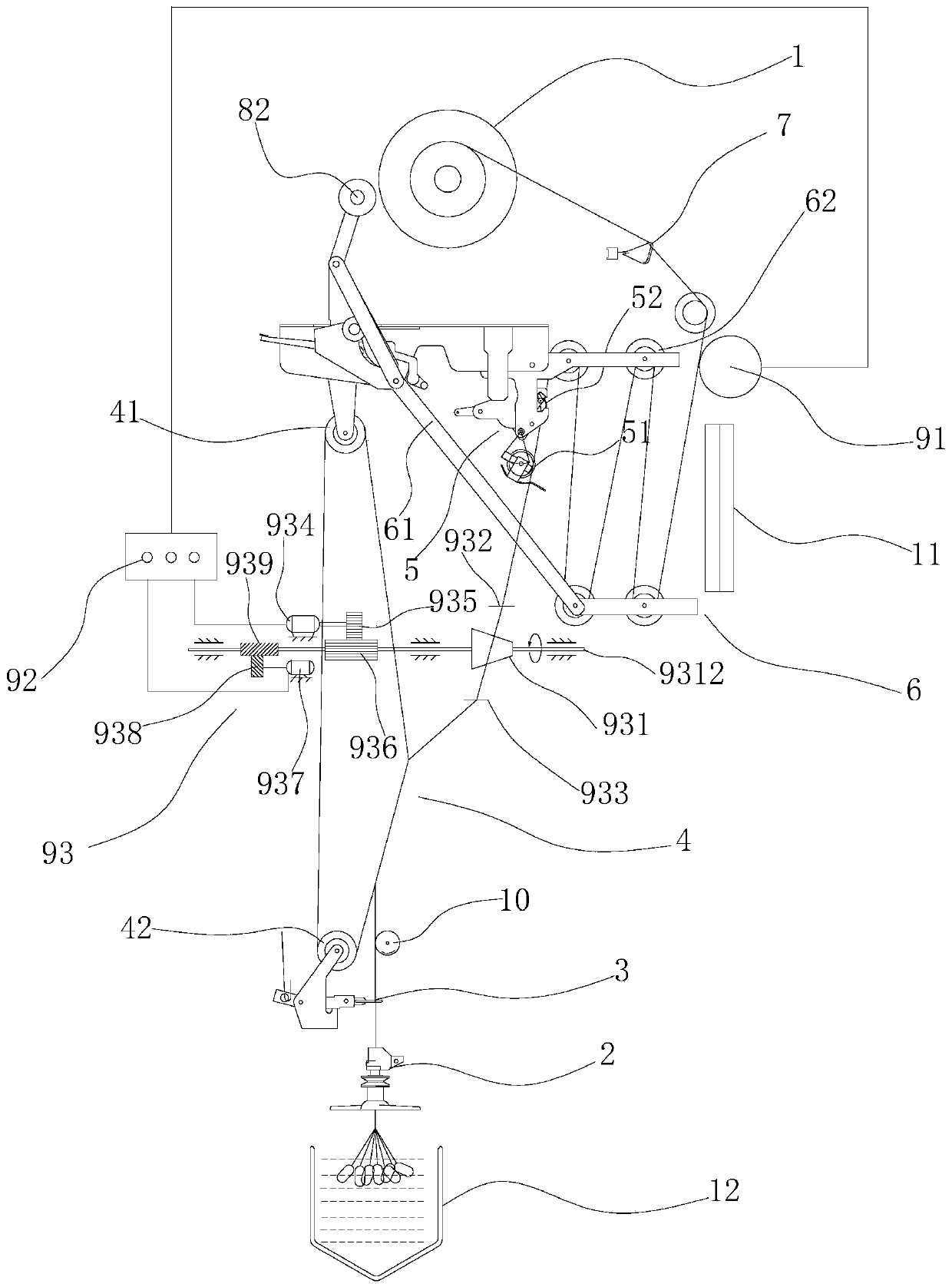

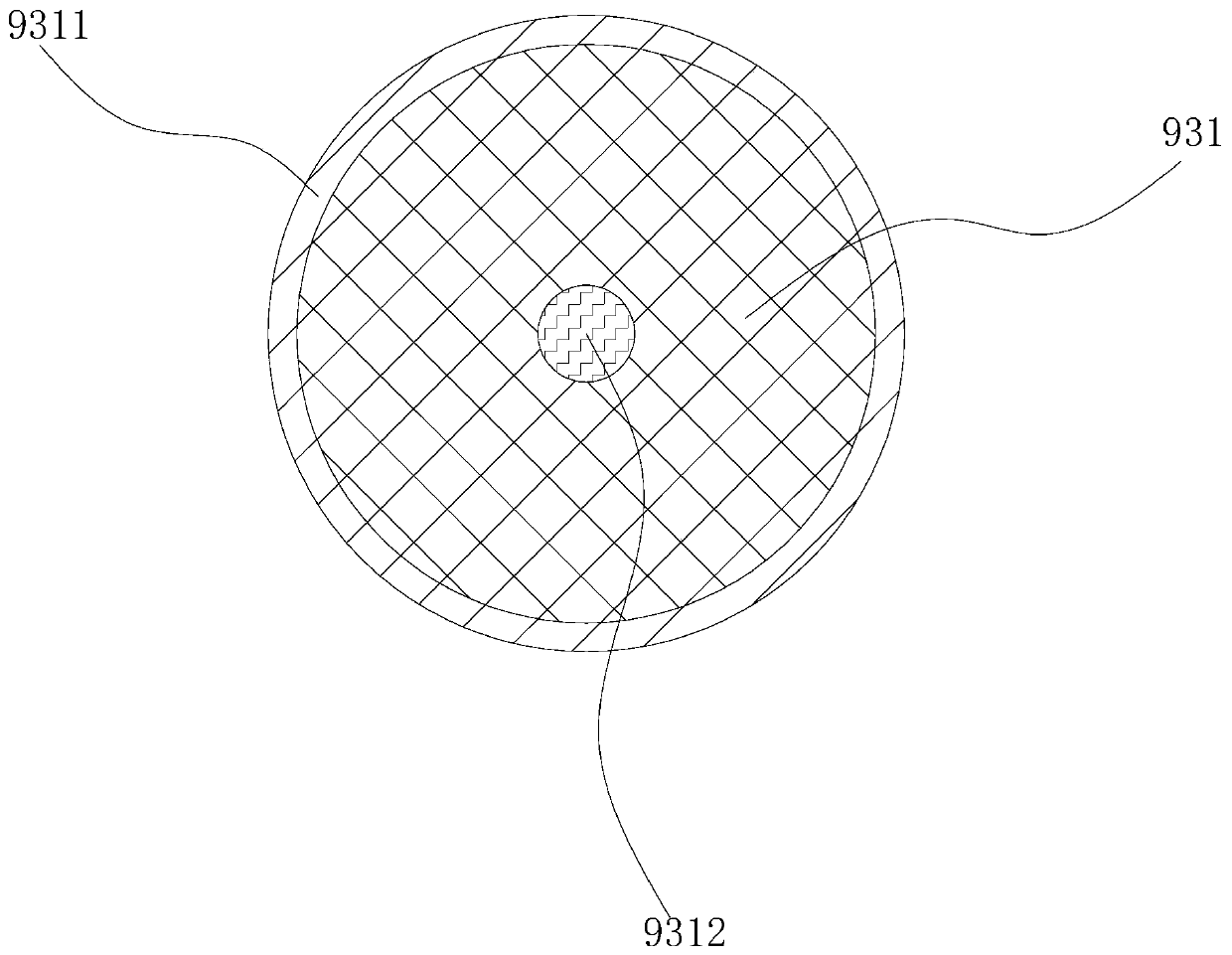

[0028] Such as figure 2 As shown, a silk-making device for reducing broken wires includes a winding group 1 and several thread-making units. The winding group is composed of several bobbins, and these bobbins are sequentially connected in the axial direction so as to share the same winding motor 14. Each bobbin corresponds to a silk-making unit. The end of the bobbin is provided with an outer circular friction surface, and a bobbin stop wheel 82 is arranged on the side of the bobbin, and the bobbin stopping wheel rubs against the outer circular friction surface of the end of the bobbin to make the bobbin gradually stop rotating. The silk-ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com