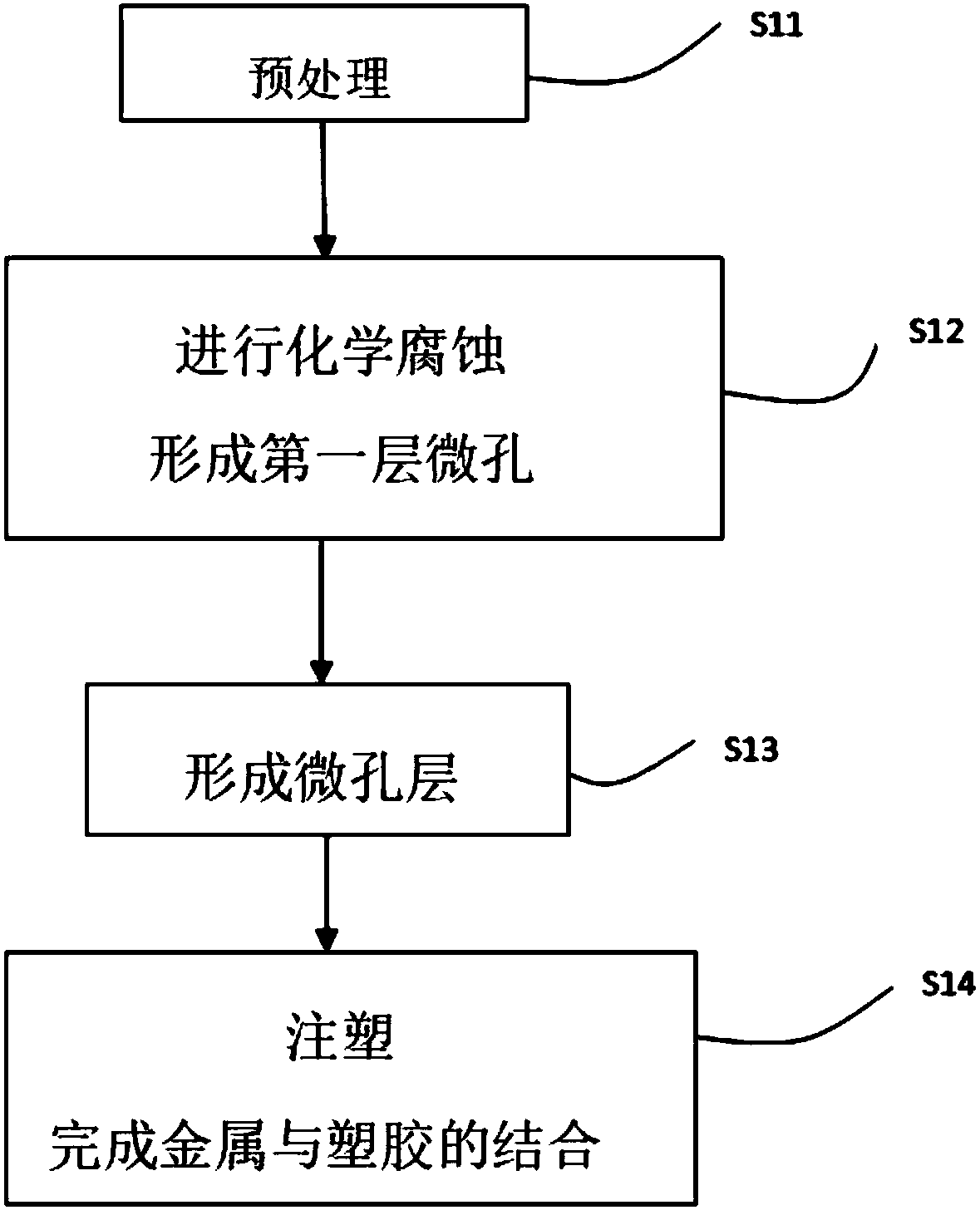

Metal and plastic binding method

A plastic and metal technology, applied in the direction of coating, can solve the problems of instability, different characteristics, unable to obtain the same results, etc., to achieve the effect of increasing stability and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

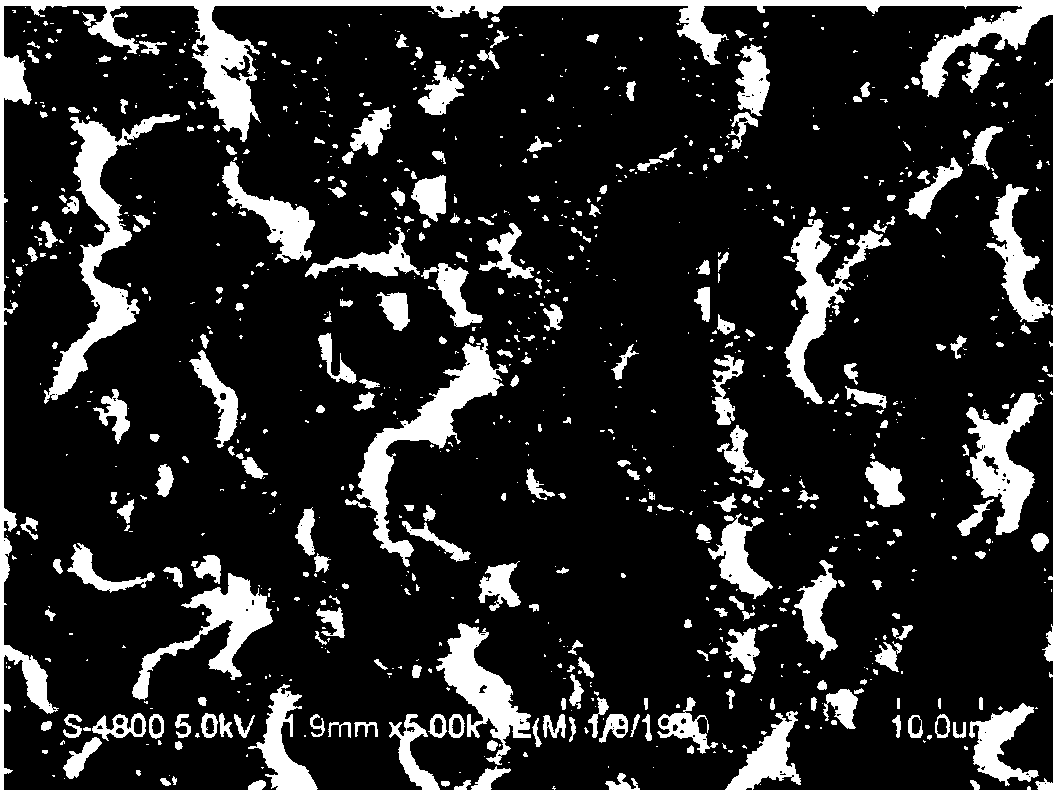

Image

Examples

Embodiment 1

[0077] The metal sample used in this embodiment is an AZ91D magnesium alloy, and the specific steps are:

[0078] – Degreasing the metal sample, using a weak alkaline degreasing agent, the temperature is 40-65 degrees, in the specific experiment, choose 55 ° C, soak for 1 to 5 minutes, choose 3 minutes in the specific experiment;

[0079] –Put the product after degreasing and cleaning into pickling. The main components of the pickling solution include nitric acid, thiourea, etc., the concentration is 100g / L, pH 1-3, the time is 1 minute, the temperature is normal temperature, the surface of the product after pickling There will be a layer of black ash;

[0080] – Put the pickled and cleaned products into neutralization. Neutralization can remove impurities and surface black ash generated during the pickling process of magnesium alloys. Neutralization uses a neutralizer with a concentration of 100g / L, and the treatment time is 60 seconds. Normal temperature treatment;

[0081...

Embodiment 2

[0088] The test method and related parameters of this embodiment are the same as those of the first embodiment, except that the injection molding rubber is replaced by PPS, and the product is cooled for 4 hours after injection molding, and the pulling force test is carried out, and the obtained bonding force value is 30-40 MPa. It can be seen that the change of injection molding material can further improve the bonding force.

Embodiment 3

[0090] The test method and relevant parameters of this embodiment are the same as those of the first embodiment, except that the metal sample is replaced by AZ91D magnesium alloy to AZ31B magnesium alloy. After being injected with PBT and cooled for 4 hours, the pulling force test is carried out to obtain the binding force value. At 27-34MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com