Beneficiation method for barite rich in calcite and witherite

A beneficiation method and barite technology, applied in flotation, solid separation and other directions, to achieve the effects of low beneficiation cost, good beneficiation index and enhanced collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The barite ore studied in the embodiment contains 76.30% of barite, 5.64% of witherite and 7.36% of calcite.

[0019] The barite ore with a particle size of -200 mesh accounting for 85% is made into a slurry with a concentration of 30%, and put into a flotation tank, and the temperature of the slurry is 28°C. The barite and witherite are flotationed with one roughing and five refining processes. Add acidified water glass 1500g / t to suppress and disperse during roughing, and stir for 5 minutes. Collect barite and witherite by using combined collectors. The combined collectors are sodium oleate 550g / t, sodium lauryl sulfate 50g / t, foaming agent terpineol oil 35g / t, and stirred for 5 minutes. When selecting, add acidic water glass to suppress and disperse, the dosage is 200g / t, 200g / t, 200g / t, 100g / t, 100g / t respectively. The grade of barium oxide in the flotation concentrate is 63.66%, and the recovery rate of barium oxide is 81.13%. Flotation concentrate density 4.23g...

Embodiment 2

[0021] The barite ore studied in the embodiment contains 76.30% of barite, 5.64% of witherite and 7.36% of calcite.

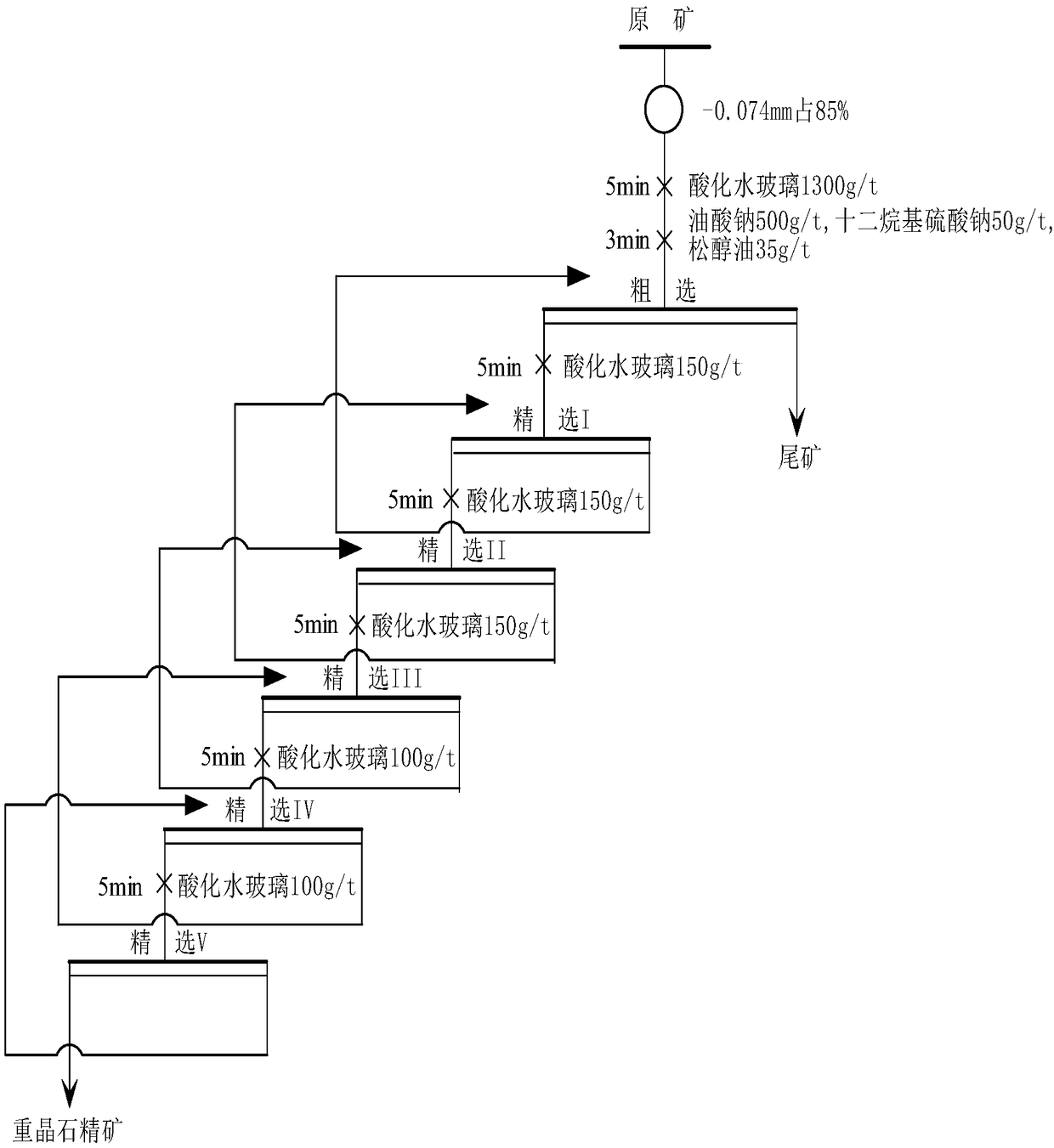

[0022] The barite ore with a particle size of -200 mesh accounting for 85% is made into a slurry with a concentration of 30%, and put into a flotation tank, and the temperature of the slurry is 28°C. The flotation operation adopts a closed-circuit test process of one rough selection and five selections. Add acidified water glass 1300g / t to suppress and disperse during roughing, and stir for 5 minutes. Add combined collectors sodium oleate 500g / t, sodium lauryl sulfate 50g / t, add terpineol oil 40g / t, and stir for 5 minutes. Add acidic water glass to inhibit and disperse during selection, the dosage is 150g / t, 150g / t, 150g / t, 100g / t, 100g / t respectively. The five selected products in the tank return to the previous process in sequence. The results of the closed-circuit test show that the yield of barite concentrate is 73.19%, the grade of barium oxide is 64.36...

Embodiment 3

[0026] A mineral processing method rich in calcite and witherite barite, comprising the following steps:

[0027] S1: Ore crushing: crush barite ore to -2mm;

[0028] S2: Grinding: Grinding the crushed barite ore, and grinding the ore to -200 mesh accounts for 60%;

[0029] S3: Preparation of flotation pulp: Put the pulp treated by S2 into the flotation machine, adjust the pulp concentration to 10%, and the pulp temperature to 25°C;

[0030] S4: Inhibition and dispersion: Add gangue mineral inhibitors to the pulp, the dosage is 500-3000g / t; fully stir evenly, the stirring speed is 500r / min, and the stirring time is 3min;

[0031] S5: Flotation of barite: add barite collector sodium oleate, dosage is 300g / t, foaming agent terpineol oil 35g / t; fully stir evenly, stirring speed is 500r / min, stirring time is 1min , Before the aerated flotation, let the barite minerals and the collector fully act, after stirring evenly, open the intake valve of the flotation machine, let the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com