Sagittaria sagittifolia Linn polysaccharide composition capable of enhancing immunologic function and preparation method of sagittaria sagittifolia Linn polysaccharide

A technology for enhancing immunity and composition, which can be used in pharmaceutical combinations, medical preparations containing active ingredients, food science, etc., can solve the problem that the immunomodulatory activity has not yet been reported, and achieve easy industrialization and amplification, no environmental pollution, and simple methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

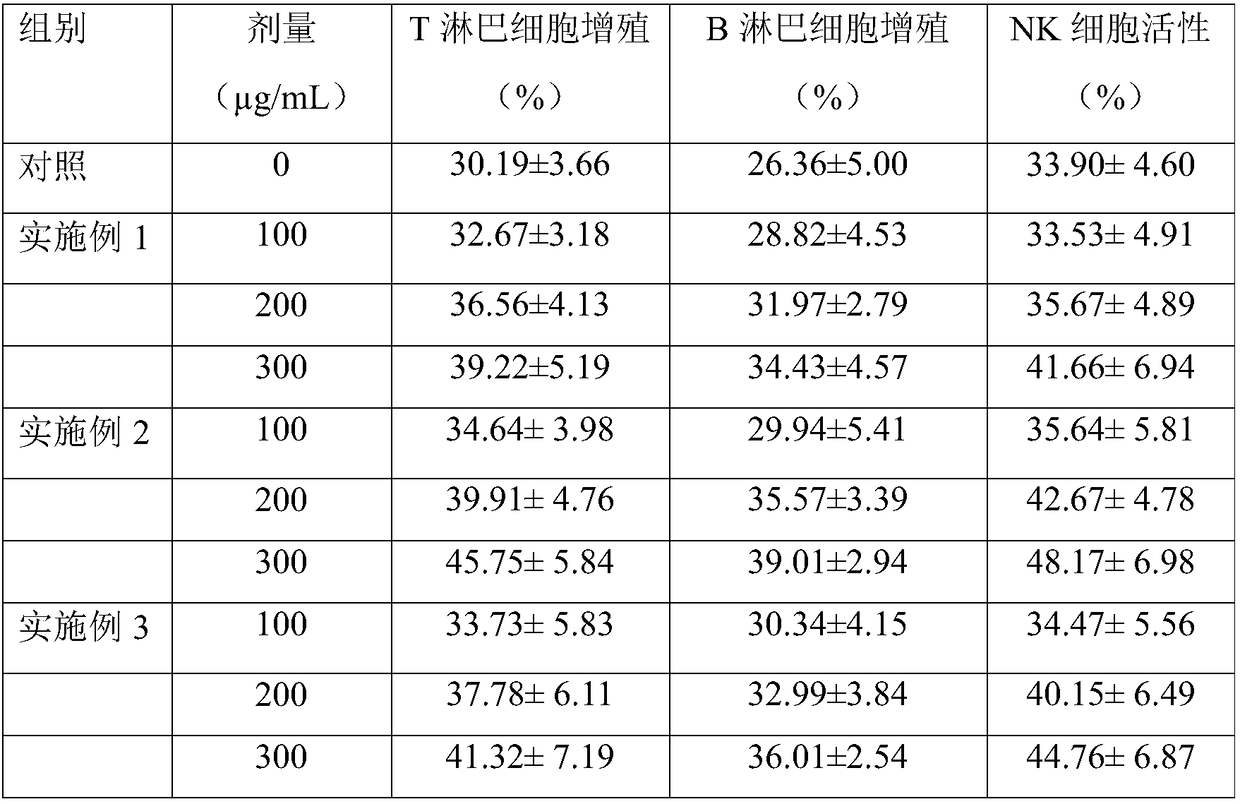

Examples

Embodiment 1

[0031] Preparation of Cigu polysaccharide: After removing impurities, washing and slicing fresh Cigu, immediately add water with a mass-to-volume ratio of 1:10 (g:mL) to make a slurry. The slurry is passed through a 60 mesh industrial filter cloth to obtain a filtrate. The filtrate is subjected to pressure The pump is injected into the subcritical extraction kettle, the magnetic coupling stirrer is controlled to 300 revolutions / min, the extraction pressure is 1MPa, the temperature is 100 ℃, and the extraction is 10 minutes. After the end, centrifuge and collect the supernatant; concentrate the supernatant to 1 / 2 of the original volume ; Add 4 times its volume of 95% ethanol to the concentrated solution, leave it for 24 hours, and centrifuge to separate the precipitate; after the precipitate is reconstituted, the DEAE-52 cellulose that has been balanced on it, first eluted with deionized water, and then It is eluted with 0.1% NaCl solution with mass fraction, and the salt eluate ...

Embodiment 2

[0034] Preparation of Cigu polysaccharide: After removing impurities, washing and slicing fresh Cigu, immediately add water with a mass-to-volume ratio of 1:10 (g:mL) to make a slurry. The slurry is passed through a 60 mesh industrial filter cloth to obtain a filtrate. The filtrate is subjected to pressure The pump is injected into the subcritical extraction kettle, the magnetic coupling stirrer is controlled at 450 rpm, the extraction pressure is 6 MPa, the temperature is 140 ℃, and the extraction is 10-30 min. After the end, centrifuge and collect the supernatant; the supernatant is concentrated to 1 of the original volume / 2; Add 4 times its volume of 95% ethanol to the concentrated solution, leave it to stand for 24 hours, and centrifuge to separate the precipitate; after the precipitate is re-dissolved, the DEAE-52 cellulose that has been balanced on it, first eluted with deionized water , And then eluted with 0.1% NaCl solution with mass fraction, collected the salt eluate...

Embodiment 3

[0037] Preparation of Cigu polysaccharide: After removing impurities, cleaning and slicing fresh Cigu, immediately add water with a mass-to-volume ratio of 1:10 (g:mL) to make a slurry. The slurry is passed through a 60 mesh industrial filter cloth to obtain a filtrate. The filtrate is passed through a pressure pump Inject into the subcritical extraction kettle, control the magnetic coupling stirrer at 600 rpm, the extraction pressure is 12MPa, the temperature is 180°C, and the extraction is 30min. After the end, centrifuge and collect the supernatant; concentrate the supernatant to 1 / 2 of the original volume; Add 4 times the volume of 95% ethanol to the concentrated solution. After standing for 24 hours, the precipitate is separated by centrifugation; after the precipitate is re-dissolved, the DEAE-52 cellulose that has been balanced is loaded, first eluted with deionized water, and then used The mass fraction of 0.1% NaCl solution is eluted, and the salt eluate is collected an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com