Photo frame testing device for evaluating in-plane shearing deformation of flexible fabrics and testing method thereof

A flexible fabric and testing device technology, which is applied to measuring devices and uses a stable shear force to test material strength, strength characteristics, etc., can solve the problems of inability to obtain shear stress and shear strain, and reduce frictional force. loss, reduce friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

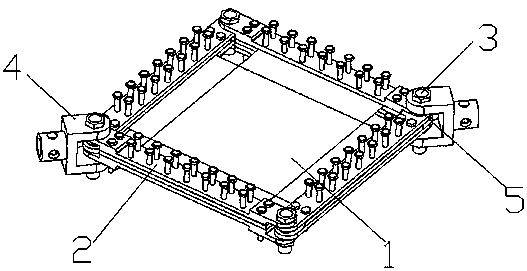

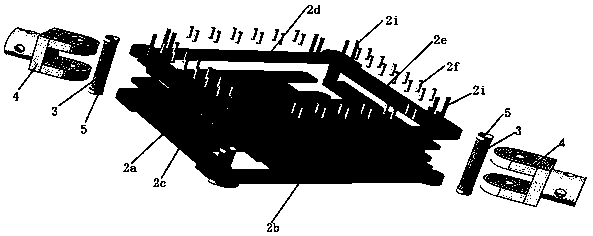

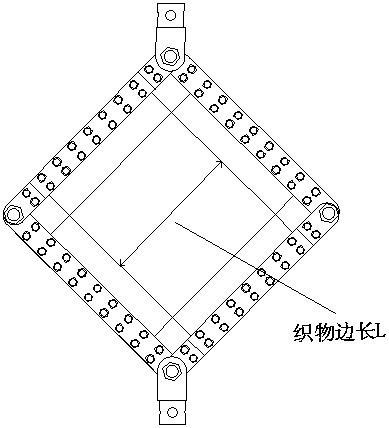

[0036] The flexible fabric in-plane shearing photo frame experiment test device consists of round head ears, pins, bearings, bottom pressing pieces, internal pressing pieces, upper pressing pieces, bolts and other parts. The flexible fabric specimen 1 is clamped 2 by the clamping fixture, and the round head and double ears 4 are connected by the pin 3, and then fixed on the working table of the testing machine by the cylindrical plug structure on the upper part of the round head and double ears. The rolling bearing 5 is fixed on the interface of the round hole where the pin contacts, so that the two clamping sides of the clamping fixture can freely rotate around the pin, and the loss of frictional force is minimized. The clamping fixture itself is divided into four parts: the bottom pressure plate 2a, the inner pressure plate 2b, the upper pressure plate 2c and the pressure bolt 2d. The edge of the fabric specimen is clamped between the bottom pressure plate and the inner press...

Embodiment 2

[0044] Embodiment 2 test method

[0045] A test method for a picture frame test apparatus for the evaluation of in-plane shear deformation of flexible fabrics, comprising the following steps:

[0046] 1) First, carry out the tensile test of the photo frame fixture device. After the installation of the photo frame fixture device is completed, the whole photo frame fixture device is fixedly installed on the testing machine platform by using the round head double-ear plug devices on the upper and lower sides of the device. Set the loading rate of the testing machine to 100mm / min to carry out the tensile test, and record the load-displacement curve of the photo frame device in real time. When the deformation of the photo frame device exceeds the shear deformation of ordinary fabrics, the experiment ends and the experimental data is saved.

[0047] 2) Convert the shear stress-shear strain relationship curve of the photo frame device. Use a specific conversion relationship to conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com