Fiber grating temperature and humidity sensor and temperature and humidity measurement system

A temperature and humidity sensor, temperature and humidity measurement technology, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, measuring devices, etc., can solve the problems of low sensitivity and measurement accuracy, and achieve high measurement accuracy and good heat resistance. and low hygroscopicity, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

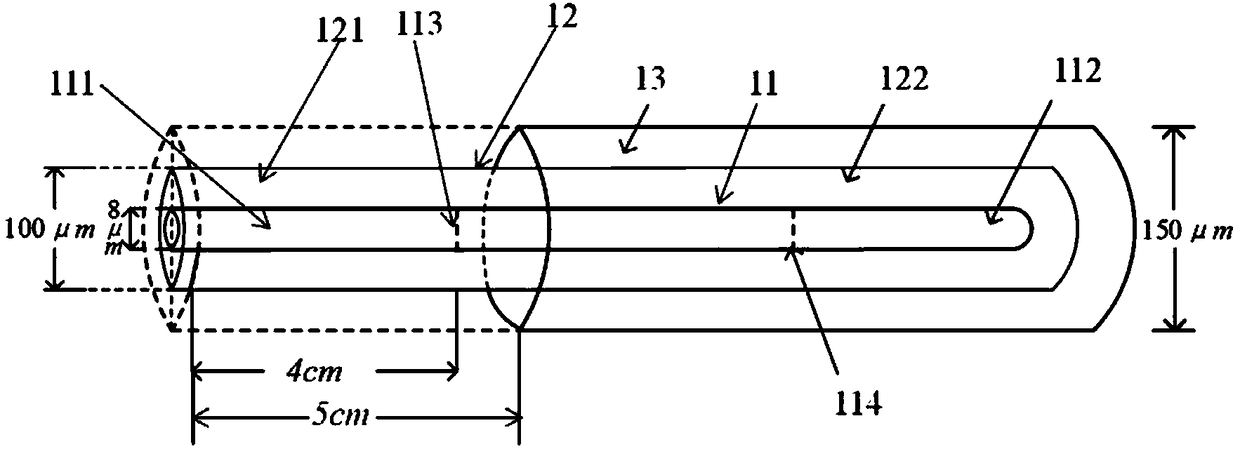

[0046] Such as figure 1As shown, the embodiment of the present application provides a fiber grating temperature and humidity sensor, including: a core 11, a cladding 12 and a protective sleeve 13, the cladding 12 is set outside the core 11, and the core 11 includes a first fiber The core segment 111 and the second core segment 112, the cladding 12 includes a first layer segment 121 and a second layer segment 122, the first layer segment 121 corresponds to the first core segment 111, and the second layer segment 122 corresponds to the second fiber segment The core segment 112 corresponds to;

[0047] The protective sleeve 13 is sleeved on the outside of the second layer section 122, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com