Pavement structure of rubber powder modified cement stabilized macadam mixture base course and proposing method of pavement structure

A cement-stabilized crushed stone and pavement structure technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems that do not meet the requirements of simplicity and high efficiency of processing, operation and laying procedures, and are practical Poor performance and other problems, to achieve the effect of simple and practical method, improve anti-deformation ability and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

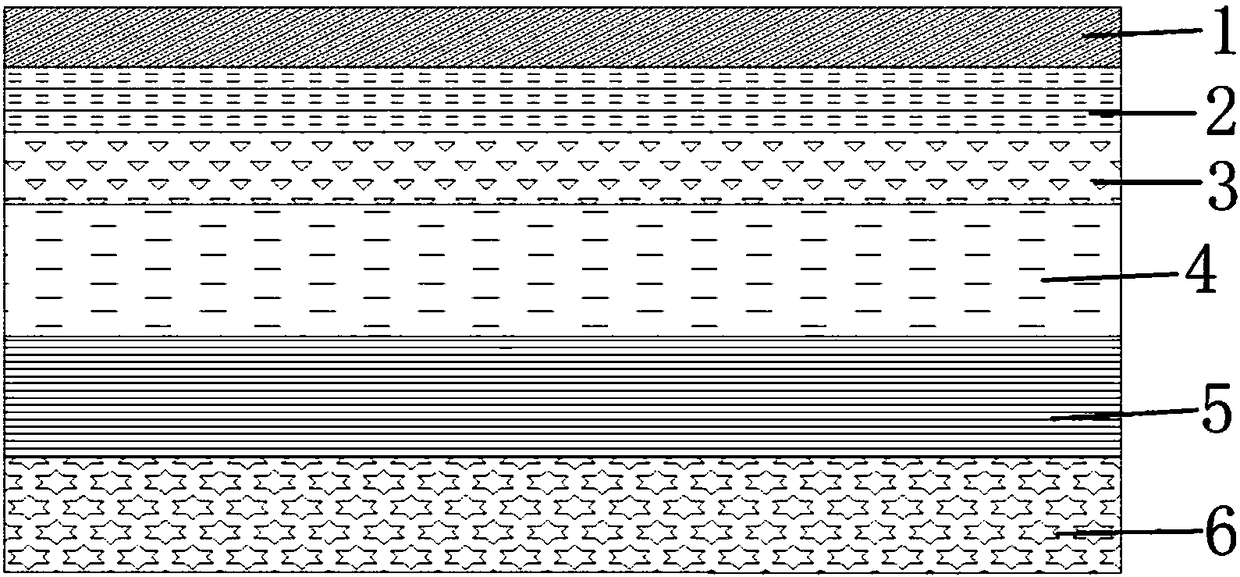

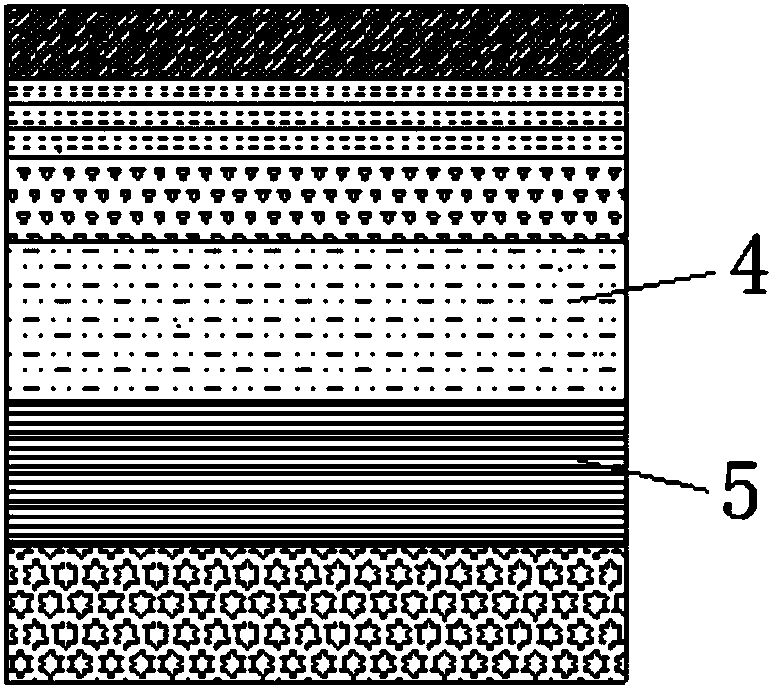

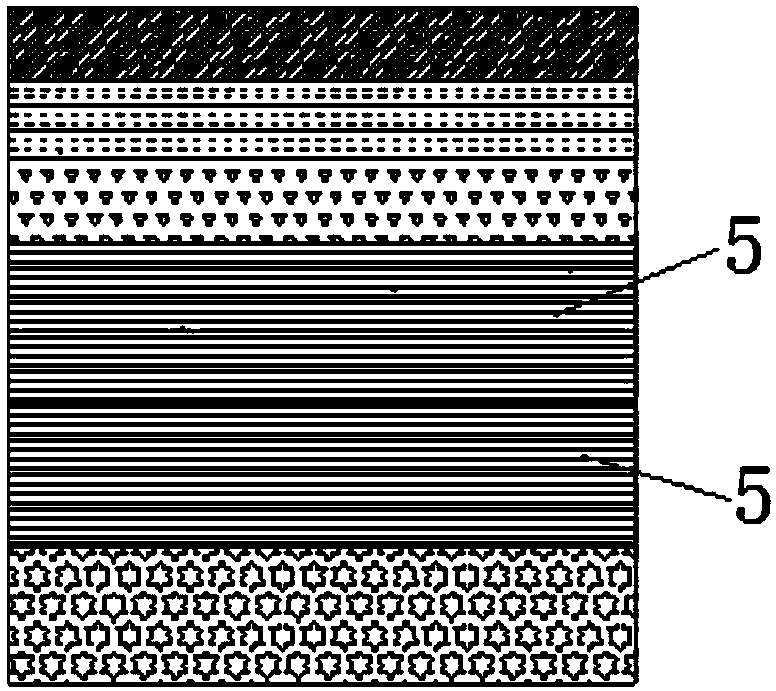

[0046] According to an embodiment of the rubber powder modified cement stabilized gravel mixture base pavement structure of the present invention, it comprises asphalt concrete pavement surface layer, rubber powder modified cement stabilized gravel mixture base, cement stabilized gravel mixture base, grade With gravel subbase and soil foundation. The thickness of the cement stabilized gravel mixture base layer in the rubber powder modified cement stabilized gravel mixture base pavement structure is 20 cm, and the compressive rebound modulus is 2000 MPa. The thickness of the base layer of the rubber powder modified cement stabilized gravel mixture is 20cm, and the compressive rebound modulus is 1000MPa.

[0047] The asphalt concrete pavement surface layer includes an upper layer, a middle layer, and a lower layer, and the thicknesses are 6, 8, and 10 cm respectively. The upper layer is the upper layer of fine-grained asphalt pavement (in this embodiment, it is the layer of fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com