Glass fiber reinforced polypropylene composite material, engine intake manifold and automobile

A glass fiber and composite material technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of high material density, complex reinforcement and modification processes, and high nylon prices, to simplify the processing process and shorten the processing. Time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

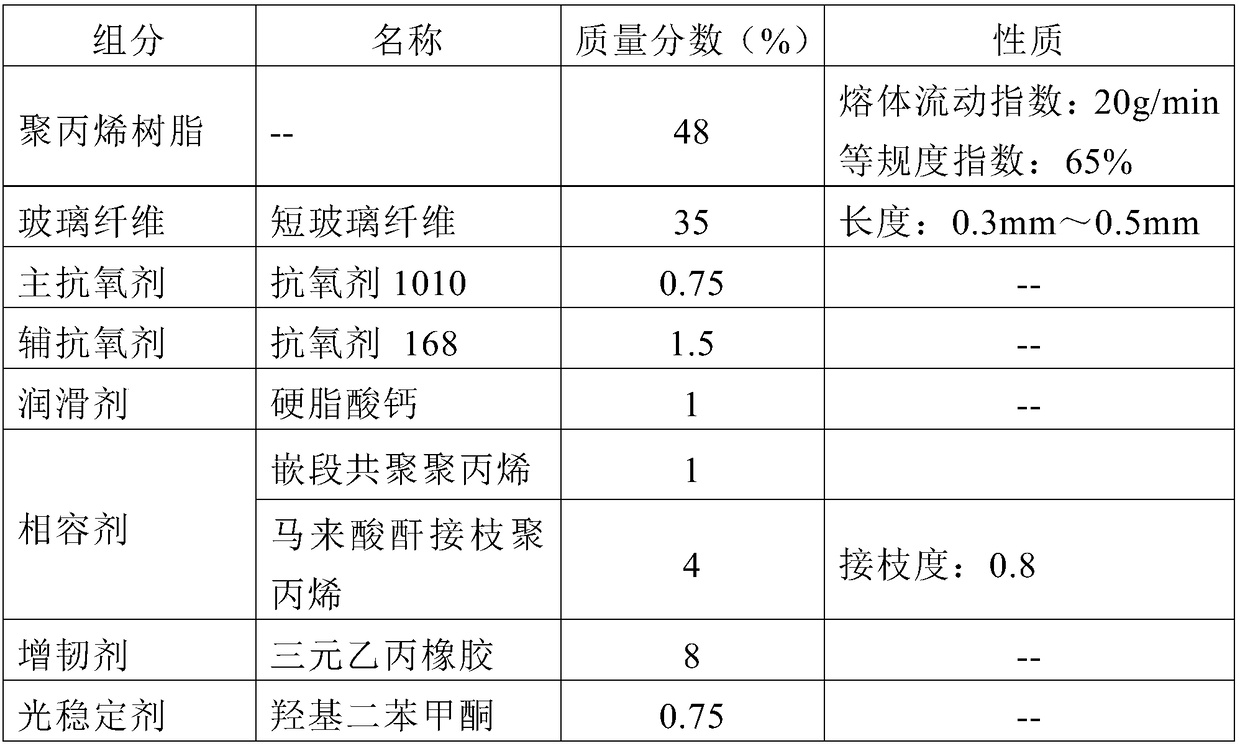

[0049] This example provides a glass fiber reinforced polypropylene composite material (referred to as PP-GF35), the components of which are shown in Table 1.

[0050] The group distribution ratio of table 1PP-GF35

[0051]

[0052] The preparation method of the above-mentioned glass fiber reinforced polypropylene composite material includes: firstly adding the components other than glass fiber into the mixer according to the ratio requirements in Table 1 and fully mixing, then adding the obtained mixture to the screw extruder Heating and melting in the machine, the temperature is about 170°C; then adding glass fiber to the screw extruder for melting and mixing, the extrusion temperature of each section (from the barrel to the machine head) is about 200°C, and the barrel temperature of the first section is relatively high. The low temperature is 150°C, and the temperature of the machine head is 190°C. Finally, the black granular glass fiber reinforced polypropylene composit...

Embodiment 2

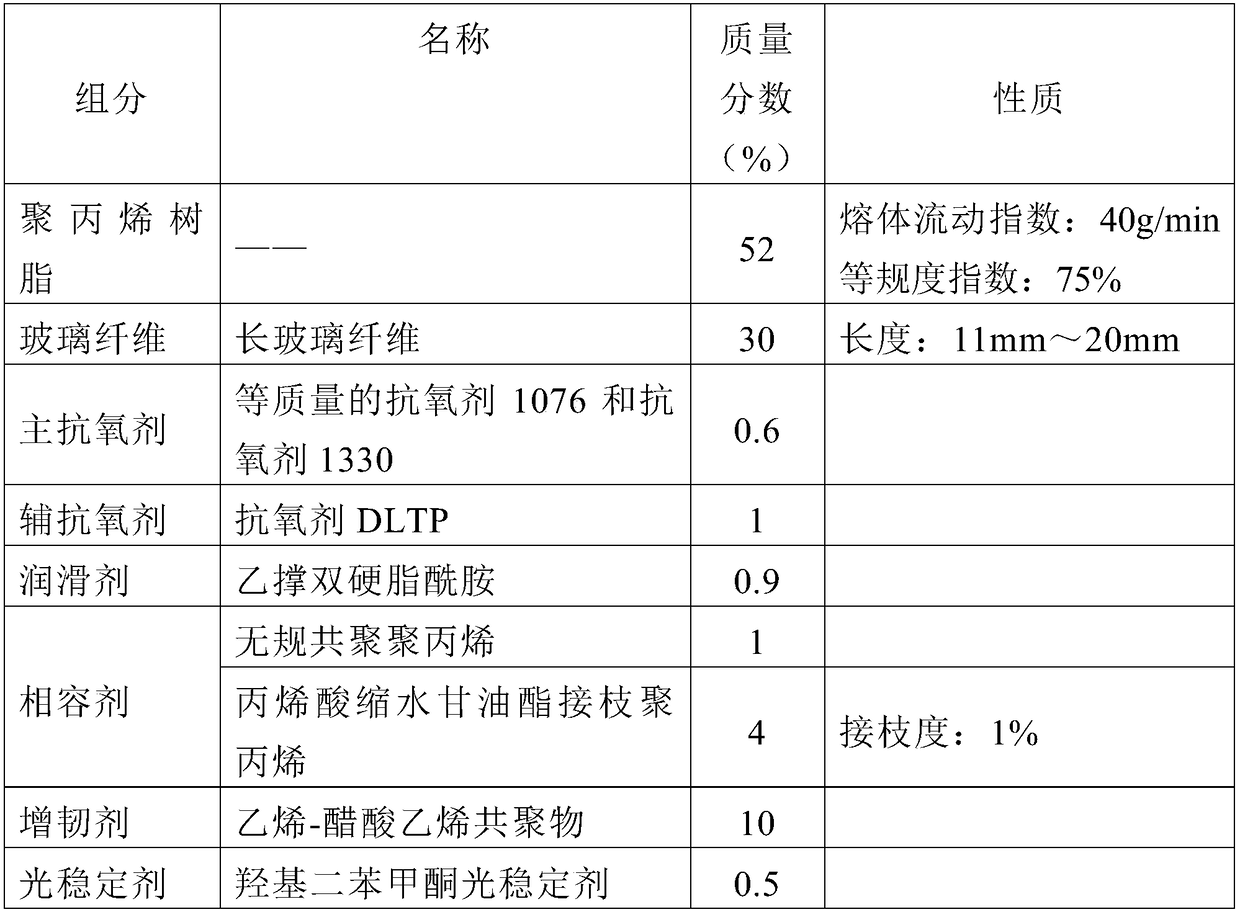

[0054] This example provides a glass fiber reinforced polypropylene composite material (referred to as PP-LGF30), the components of which are shown in Table 2.

[0055] Table 2 Component distribution ratio of PP-LGF30

[0056]

[0057] The preparation method of the above-mentioned glass fiber reinforced polypropylene composite material includes: first, adding the components other than glass fibers into the mixer according to the ratio requirements in Table 2 and fully mixing, and adding the obtained mixture to the screw extruder Heating and melting in the machine, the temperature is about 175°C; then adding glass fiber to the screw extruder for melting and mixing, the extrusion temperature of each section (from the barrel to the head) is about 205°C, and the barrel temperature of the first section is relatively high. The low temperature is 160°C, and the temperature of the machine head is 200°C. Finally, the black granular glass fiber reinforced polypropylene composite mate...

Embodiment 3

[0068] With the glass fiber reinforced polypropylene composite material (PP-GF35) in embodiment 1 as raw material, manufacture engine intake manifold, specifically comprise the steps:

[0069] (1) The black granular raw material is directly inhaled into the screw of the injection molding machine for heat treatment without being dried, and after the raw material is gradually softened into a liquid state, it is sprayed into the mold for injection molding, and the injection molding can be completed to obtain the intake manifold Fragmentation, where:

[0070] The injection molding temperature is 210°C-230°C, the pressure is about 70bar-80bar (7.0MPa-8.0MPa), and the holding time is 5S. Specifically, the corresponding temperature data at the four sensing zones and nozzles of the injection molding machine can be found in Table 5.

[0071] (2) After the injection molding is completed, open the mold, take out the prepared intake manifold segments from the mold, and cool to about 25°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Burst strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com