Organic slow-release fertilizer with function of improving soil, and preparation method of organic slow-release fertilizer

A technology for improving soil and slow-release fertilizers, applied in the direction of organic fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of quality decline, low fertilizer utilization rate, soil degradation, etc., and achieve the effect of improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

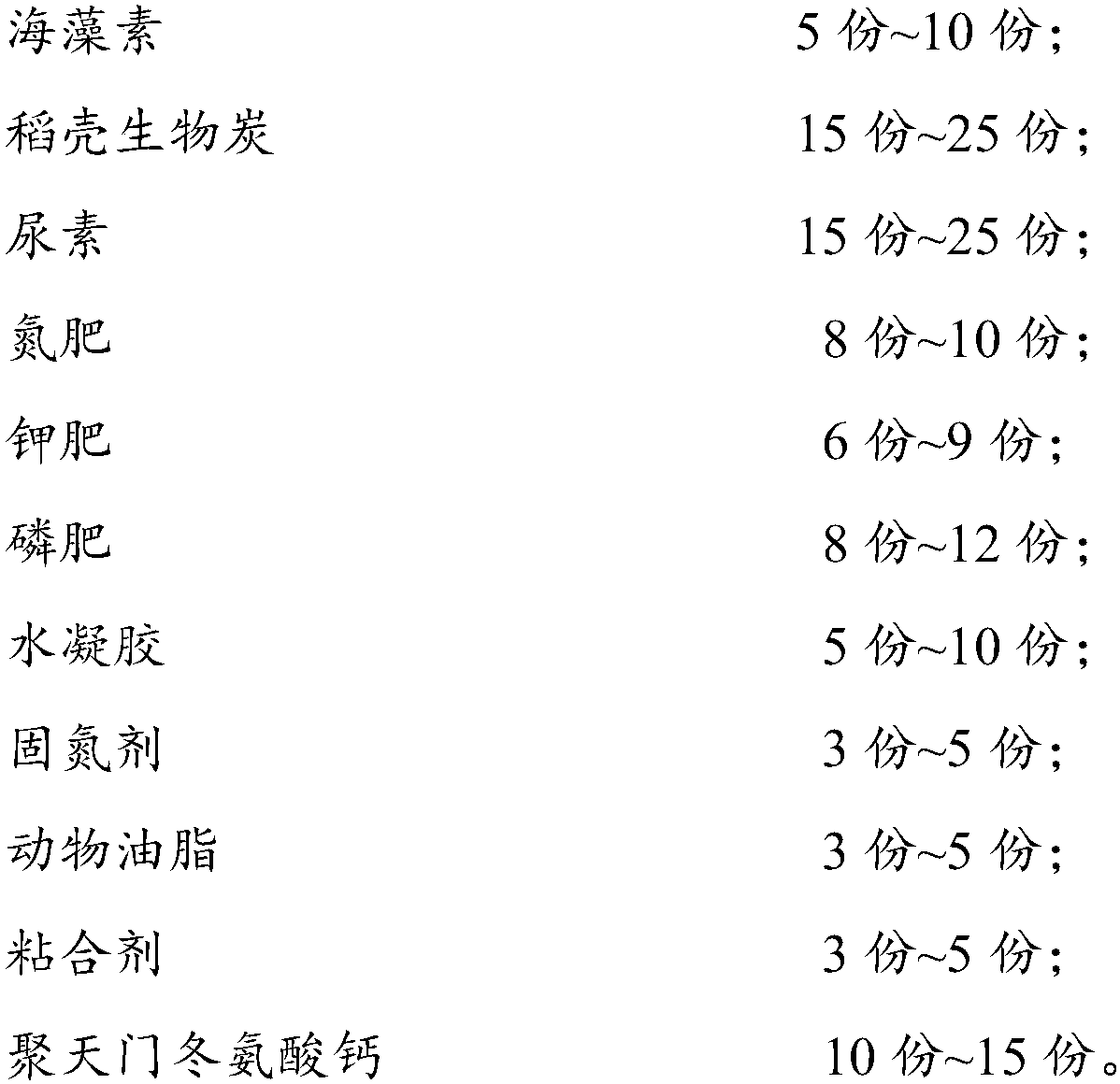

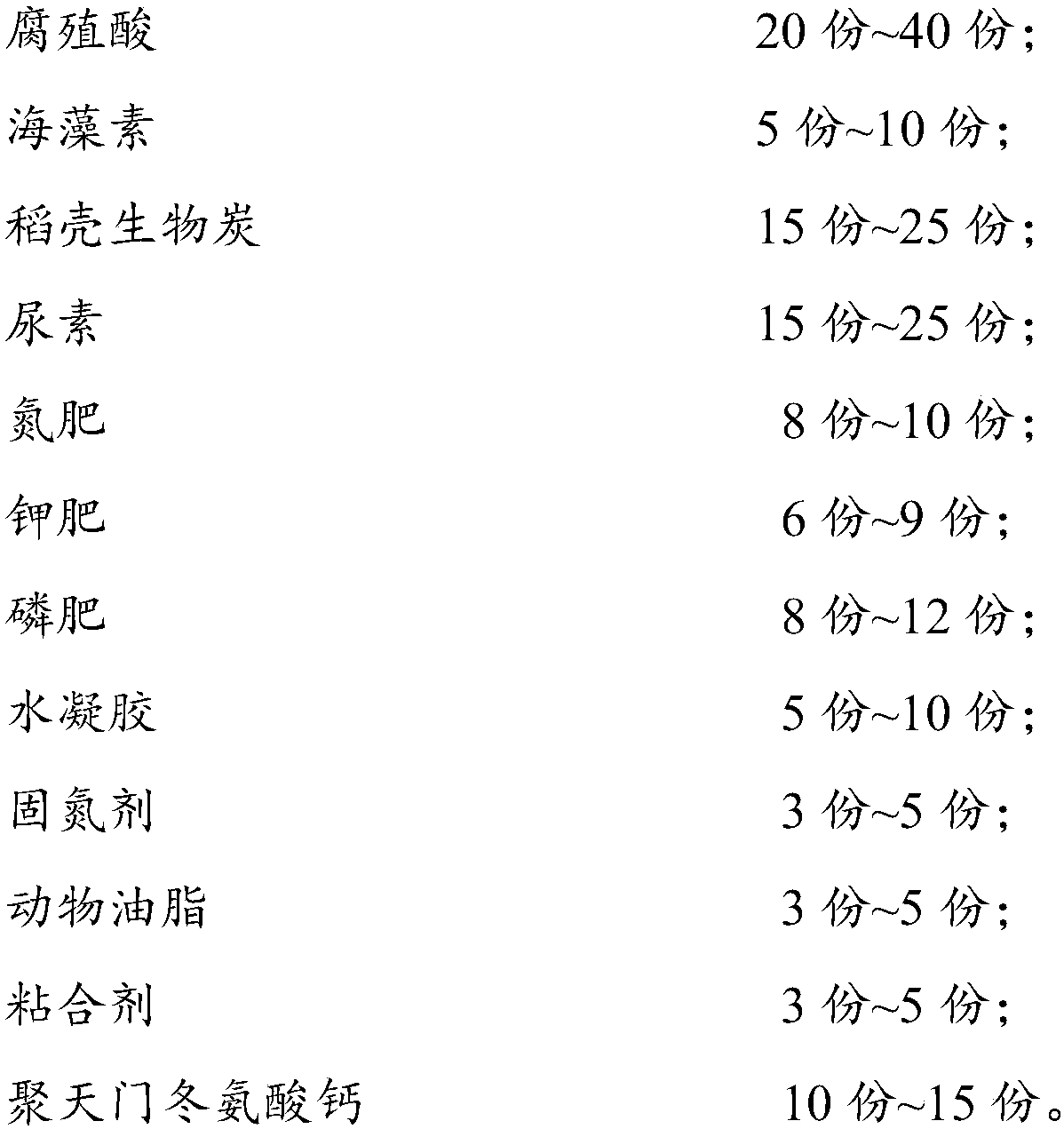

[0025] Embodiment 1, present embodiment provides a kind of organic slow release fertilizer of improving soil

[0026] First weigh 20kg of humic acid; 5kg of seaweed; 15kg of rice husk biochar; 15kg of urea; 8kg of nitrogen fertilizer; 6kg of potassium fertilizer; Calcium aspartate 10kg, then, after mixing humic acid, seaweed, rice husk biochar, urea, nitrogen fertilizer, potassium fertilizer, phosphate fertilizer and polyaspartate calcium, add brown sugar water, stir well, and stir into a viscous It can be thickened, granulated, and the mother nucleus is obtained for use. The ratio of brown sugar and water in brown sugar water is 6:100. The purpose of choosing brown sugar water is mainly to provide a certain viscosity and bind the raw materials together. In this embodiment , the particle size is between 1mm and 1.5mm.

[0027] Then, the animal fat is indirectly heated and melted by steam, and then pumped into the coating drum by the metering oil pump, and the mother core is p...

Embodiment 2

[0030] Embodiment 2, present embodiment provides a kind of organic slow release fertilizer of improving soil

[0031] First weigh 40kg of humic acid; 10kg of seaweed; 25kg of rice husk biochar; 25kg of urea; 10kg of nitrogen fertilizer; 9kg of potassium fertilizer; Calcium aspartate 15kg, then, mix humic acid, seaweed, rice husk biochar, urea, nitrogen fertilizer, potassium fertilizer, phosphate fertilizer and calcium polyaspartate evenly, add brown sugar water, stir to become viscous Yes, stir evenly, granulate, and obtain the mother nucleus for use. The ratio of brown sugar and water in brown sugar water is 6:100. The purpose of choosing brown sugar water is mainly to provide a certain viscosity and bind the raw materials together. In this embodiment , the particle size is between 1mm and 1.5mm.

[0032] Then, the animal fat is indirectly heated and melted by steam, and then pumped into the coating drum by the metering oil pump, and the mother core is poured into the coatin...

Embodiment 3

[0034] Embodiment 3, present embodiment provides a kind of organic slow release fertilizer of improving soil

[0035]First weigh 30kg of humic acid; 8kg of seaweed; 22kg of rice husk biochar; 20kg of urea; 9kg of nitrogen fertilizer; 8kg of potassium fertilizer; Calcium aspartate 12kg, then, after mixing humic acid, seaweed, rice husk biochar, urea, nitrogen fertilizer, potassium fertilizer, phosphate fertilizer and polyaspartate calcium, add brown sugar water, stir well, and stir into a viscous Just thick. Granulate to obtain the mother nucleus for use. The ratio of brown sugar and water in brown sugar water is 6:100. The purpose of selecting brown sugar water is mainly to provide a certain viscosity and bind the raw materials together. In this embodiment, the particle size is 1mm ~1.5mm.

[0036] Then, the animal fat is indirectly heated and melted by steam, and then pumped into the coating drum by the metering oil pump, and the mother core is poured into the coating drum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com