Full-membrane separation method for producing lithium extraction mother liquor from salt lake brine multistage nanofiltration

A technology for salt lake brine and lithium extraction mother liquor, which is applied in the field of membrane separation, can solve the problems of limited magnesium and lithium separation capacity, poor brine treatment effect, and failure to obtain local materials, achieves wide water quality, is conducive to popularization and application, and has flexible design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

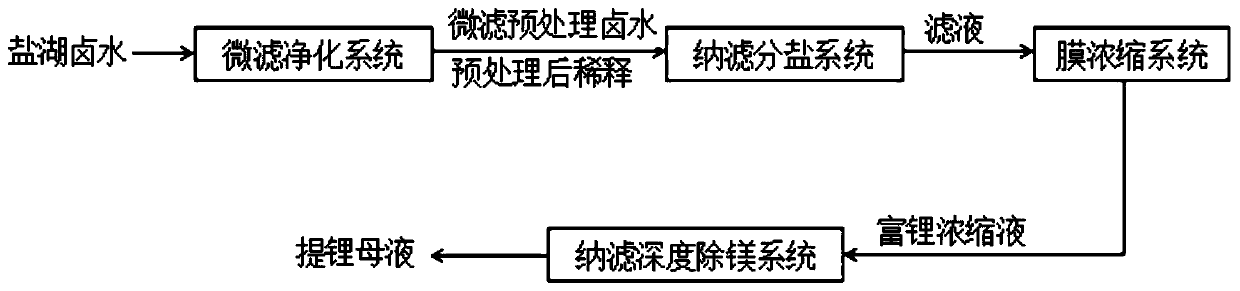

[0035] figure 1 A flow chart of the method of the present invention is given. In the present invention, the full-membrane separation process for producing lithium-extracting mother liquor by multi-stage nanofiltration and salt separation of salt lake brine has multiple implementation modes, including the following steps:

[0036] (1) Use a microfiltration purification system to pretreat salt lake brine to remove suspended solids, colloids and other impurities, and then dilute it with fresh water 2 to 5 times to obtain microfiltration pretreated brine.

[0037] Among them, the magnesium-lithium ratio of salt lake brine is (10-1000):1 by mass ratio, the mass concentration of lithium ions is 0.1-5 g / L, and the pH value is 5-7.5.

[0038]The number of stages of the microfiltration purification system is 1 to 2, which is composed of one or two of the filtration precisions of 1 to 5 μm, 0.45 to 1 μm or 0.1 to 0.45 μm according to the pore size; The material of the filter membrane ...

Embodiment 1

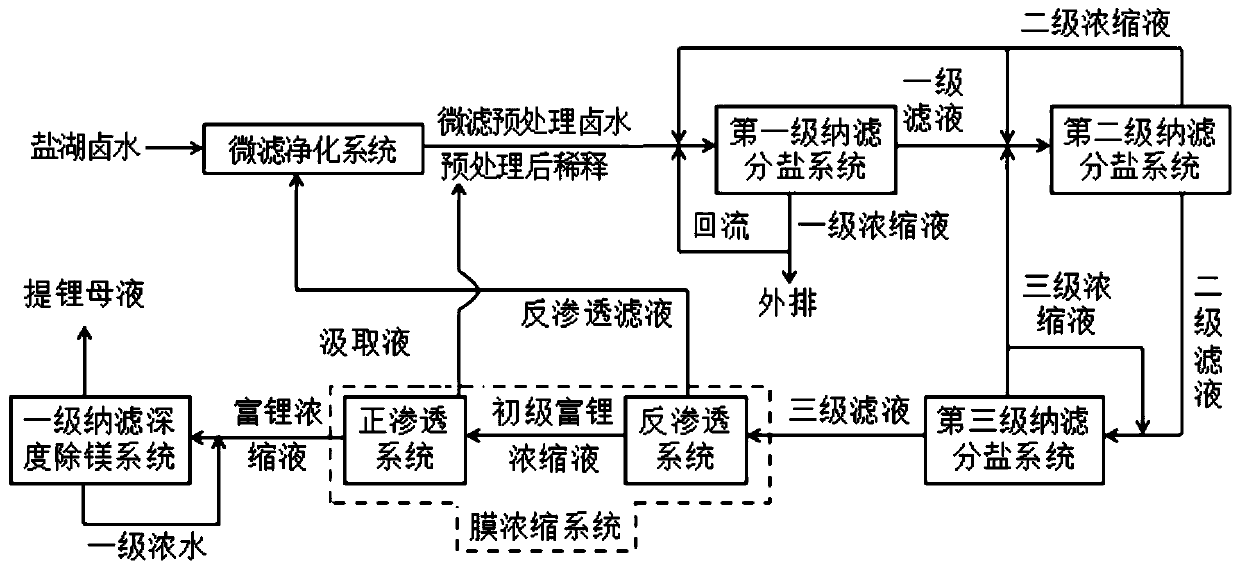

[0053] Such as figure 2 As shown, in this embodiment, a three-stage nanofiltration salt separation system, a forward osmosis and reverse osmosis system, and a nanofiltration deep magnesium removal system are selected. Include the following steps:

[0054] (1) Use the microfiltration purification system to treat salt lake brine with pH=5, the mass concentration of magnesium ions is 115.10g / L, the mass concentration of lithium ions is 0.384g / L, and the ratio of magnesium to lithium (by mass ratio) is 300:1 Pretreatment is carried out to remove suspended solids, colloids and other impurities, and then diluted 2.5 times with fresh water to obtain microfiltration pretreated brine.

[0055] Among them, the microfiltration purification system is composed of two microfiltration systems with a filtration precision of 3 μm and 0.22 μm in sequence, and the materials of the microfiltration membrane are polycarbonate and polysulfone in sequence.

[0056] (2) Send the microfiltration pre...

Embodiment 2

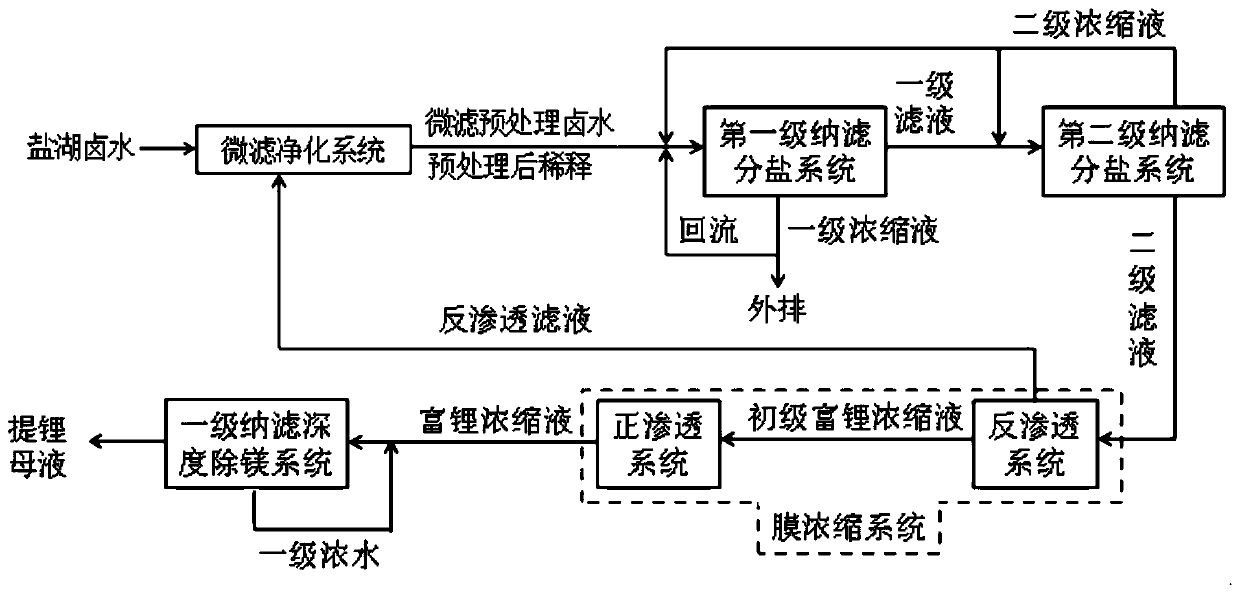

[0070] Such as image 3 As shown, the present embodiment selects a two-stage nanofiltration salt separation system, which is one level less than the nanofiltration salt separation system in Example 1. Except for the following differences, other parts are the same as in Example 1. In this example:

[0071] (1) The pH of salt lake brine is 6.4, the mass concentration of magnesium ions is 51.75g / L, the mass concentration of lithium ions is 0.535g / L, the ratio of magnesium to lithium (by mass ratio) is 100:1, and the salt lake brine is diluted 5 times, The microfiltration purification system is composed of two microfiltration systems with a filtration precision of 1 μm and 0.1 μm in sequence. The materials of the microfiltration membrane are polypropylene and polyvinylidene fluoride in sequence.

[0072] (2) present embodiment selects two-stage nanofiltration salt separation system for use, and the first stage nanofiltration salt separation system uses DT nanofiltration membrane,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com