A fluorescent type phosphorus-free scale inhibitor

A phosphorus-free scale inhibitor, fluorescent technology, used in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. Scaling, difficult agent concentration and other problems, to achieve excellent scale inhibition performance, solve the scaling problem, and avoid the effect of eutrophication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

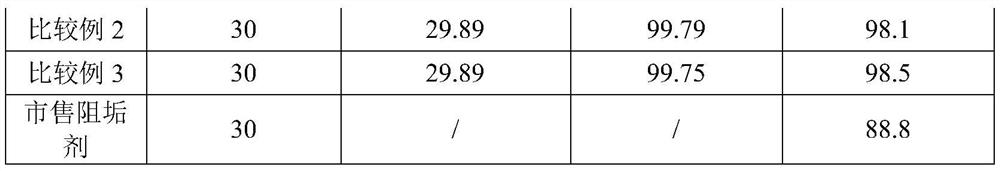

Examples

Embodiment 1

[0032] The specific preparation process of the fluorescent phosphorus-free scale inhibitor is as follows:

[0033] 1. Batching each raw material according to the following parts by mass:

[0034] 10 parts of maleic acid-acrylic acid copolymer, 25 parts of polyepoxysuccinic acid, 15 parts of acrylic acid-sulfonic acid-amide copolymer, 18 parts of acrylic acid-acrylate-sulfonate copolymer, 8 parts of polyaspartic acid , 0.15 parts of 1,3,6,8-pyrenetetrasulfonic acid tetrasodium salt and 10 parts of water;

[0035] 2. The above raw materials were prepared according to maleic acid-acrylic acid copolymer, polyepoxysuccinic acid, acrylic acid-sulfonic acid-amide copolymer, acrylic acid-acrylate-sulfonate copolymer, polyaspartic acid, 1,3 ,6,8-Pyrene tetrasodium salt and water are added to the stirring tank in sequence, and the mixing and stirring are started;

[0036] 3. The temperature of the stirring tank is set to 70℃, normal pressure, the stirring speed is 140rpm, and the stir...

Embodiment 2

[0039] The specific preparation process of the fluorescent phosphorus-free scale inhibitor is as follows:

[0040] 1. Batching each raw material according to the following parts by mass:

[0041] 15 parts of maleic acid-acrylic acid copolymer, 20 parts of polyepoxysuccinic acid, 20 parts of acrylic acid-sulfonic acid-amide copolymer, 12 parts of acrylic acid-acrylate-sulfonate copolymer, 12 parts of polyaspartic acid , 0.1 part of 1,3,6,8-pyrenetetrasulfonic acid tetrasodium salt and 15 parts of water;

[0042] 2. The above raw materials were prepared according to maleic acid-acrylic acid copolymer, polyepoxysuccinic acid, acrylic acid-sulfonic acid-amide copolymer, acrylic acid-acrylate-sulfonate copolymer, polyaspartic acid, 1,3 ,6,8-Pyrene tetrasodium salt and water are added to the stirring tank in sequence, and the mixing and stirring are started;

[0043] 3. The temperature of the stirring tank is set to 50℃, normal pressure, the stirring speed is 100rpm, and the stirr...

Embodiment 3

[0046] The specific preparation process of the fluorescent phosphorus-free scale inhibitor is as follows:

[0047] 1. Batching each raw material according to the following parts by mass:

[0048]11 parts of maleic acid-acrylic acid copolymer, 24 parts of polyepoxysuccinic acid, 17 parts of acrylic acid-sulfonic acid-amide copolymer, 17 parts of acrylic acid-acrylate-sulfonate copolymer, 9 parts of polyaspartic acid , 0.15 parts of 1,3,6-naphthalene trisulfonic acid trisodium salt and 11 parts of water;

[0049] 2. The above raw materials were prepared according to maleic acid-acrylic acid copolymer, polyepoxysuccinic acid, acrylic acid-sulfonic acid-amide copolymer, acrylic acid-acrylate-sulfonate copolymer, polyaspartic acid, 1,3 , The order of 6-naphthalene trisulfonic acid trisodium salt and water is successively added in the stirring tank, and the mixing and stirring are started;

[0050] 3. The temperature of the stirring tank is set to 60℃, normal pressure, the stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com