Numerically-controlled vertical drilling device

A drilling device, digitally controlled vertical technology, applied in the field of numerically controlled vertical drilling devices, can solve the problems of cumbersome operation, low efficiency, lack of waste collection, etc., and achieve the effect of improving accuracy and efficiency and strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

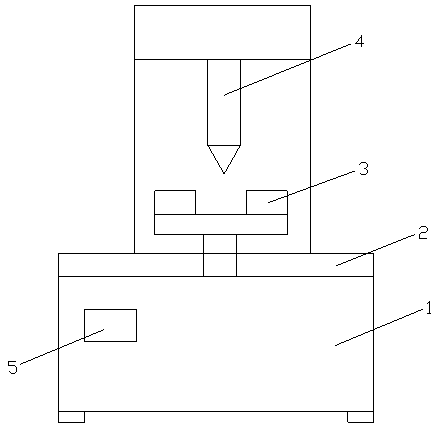

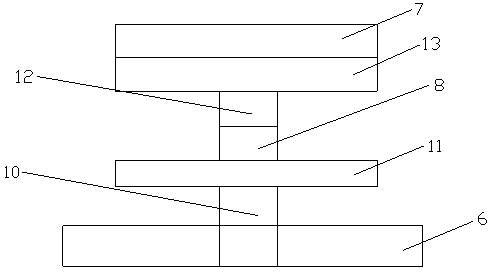

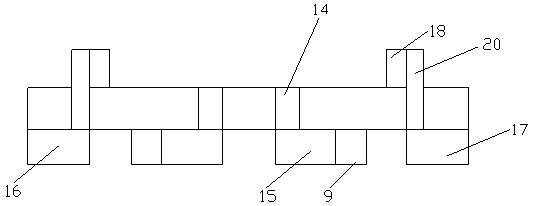

[0043] like Figure 1-6 As shown, a numerical control vertical drilling device includes a mechanical support 1, a positioning mechanism 2, a clamping mechanism 3, a drilling mechanism 4 and a control device 5, and the positioning mechanism 2, the drilling mechanism 4 and the control device 5 are all Installed on the mechanical support 1, the positioning mechanism 2 includes an electric guide rail 6, a rotating disk 7, a rotating motor 8 and a negative pressure fan 9, and the slider of the electric guide rail 6 is provided with a connecting rod 10, and the connecting rod 10 A fixed disk 11 is arranged on the fixed disk 11, and a rotary motor 8 is installed on the fixed disk 11. A speed reducer 12 is arranged on the transmission shaft of the rotary motor 8, and a speed reducer 13 is arranged on the output shaft of the speed reducer 12. A rotary disc 7 is installed on the deceleration disc 13, and the rotary disc 7 is provided with a waste material hole 14, and more than one wast...

Embodiment 2

[0051] like Figure 1-6 As shown, a numerical control vertical drilling device includes a mechanical support 1, a positioning mechanism 2, a clamping mechanism 3, a drilling mechanism 4 and a control device 5, and the positioning mechanism 2, the drilling mechanism 4 and the control device 5 are all Installed on the mechanical support 1, the positioning mechanism 2 includes an electric guide rail 6, a rotating disk 7, a rotating motor 8 and a negative pressure fan 9, and the slider of the electric guide rail 6 is provided with a connecting rod 10, and the connecting rod 10 A fixed disk 11 is arranged on the fixed disk 11, and a rotary motor 8 is installed on the fixed disk 11. A speed reducer 12 is arranged on the transmission shaft of the rotary motor 8, and a speed reducer 13 is arranged on the output shaft of the speed reducer 12. A rotary disc 7 is installed on the deceleration disc 13, and the rotary disc 7 is provided with a waste material hole 14, and more than one wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com