Method for combined remediation of heavy metal in soil through biomass charcoal-plant-microorganism

A technology of biochar and joint repair, applied in the restoration of polluted soil, etc., can solve the problems of low removal efficiency of heavy metals, increase soil fertility, etc., and achieve the effect of simple implementation, good application prospects, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The collected peanut shells are passed through sieving soil and transferred into a downdraft biomass carbonization furnace, where they are pyrolyzed at 600°C under anaerobic conditions for 1.5 hours to make biomass charcoal, and then ground to 80 meshes for use.

[0021] Bacillus subtilis was cultured in a nutrient solution at a ratio of 0.01 g / L, and the nutrient solution ratio used was shown in Table 1, and the mixture was bottled for use.

[0022] Table 1 The ratio of nutrient solution

[0023] Nutrient solution composition

Peptone

NaCl

glucose

water

pH

Ingredient content

3g

10g

5g

10g

1L

7.4-7.6

[0024] Dilute the prepared bacterial suspension with distilled water, with a dilution ratio of 1:3, for use

[0025] Soak the Paspalum notatum seeds in warm water for 24 hours and set aside.

Embodiment 2

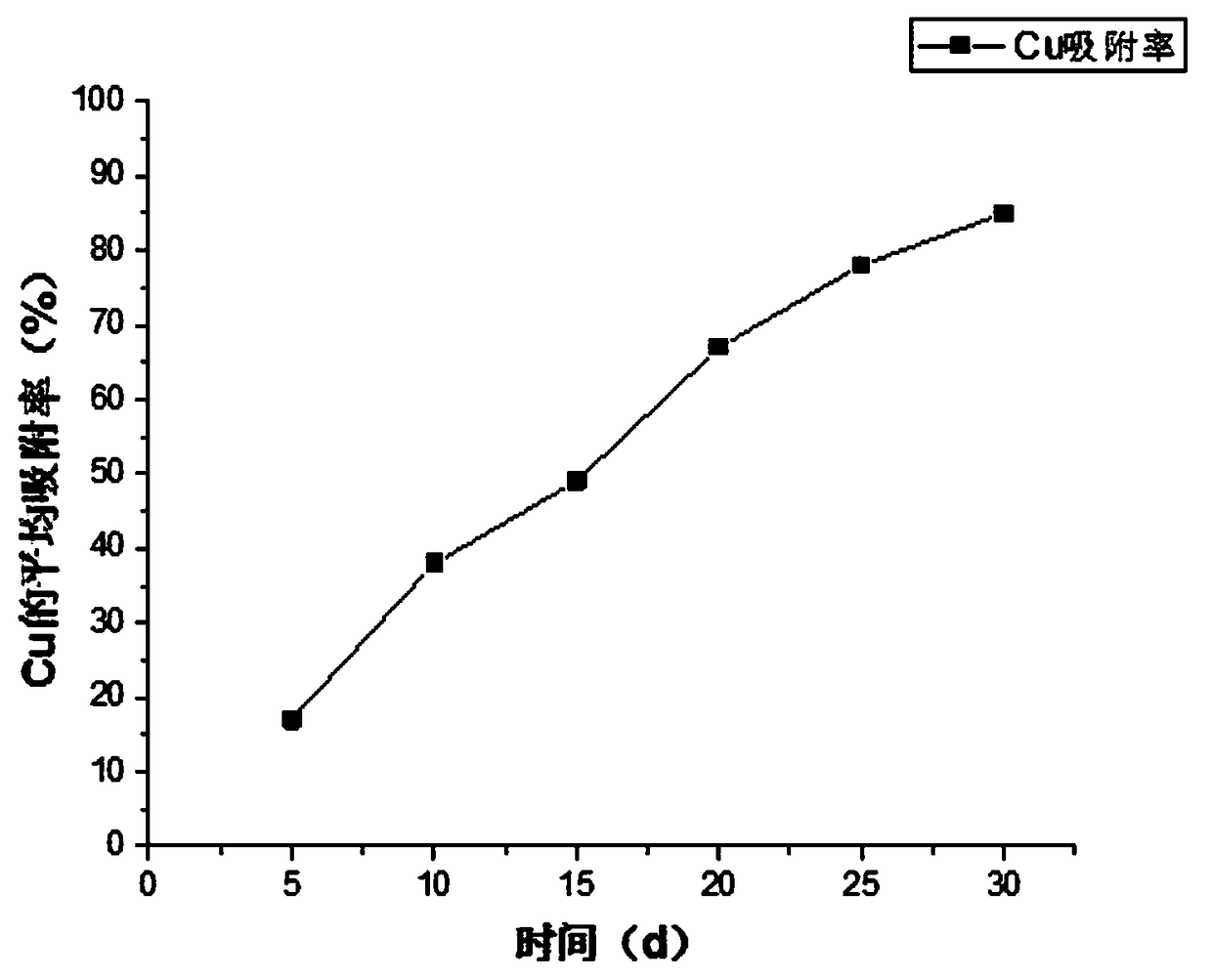

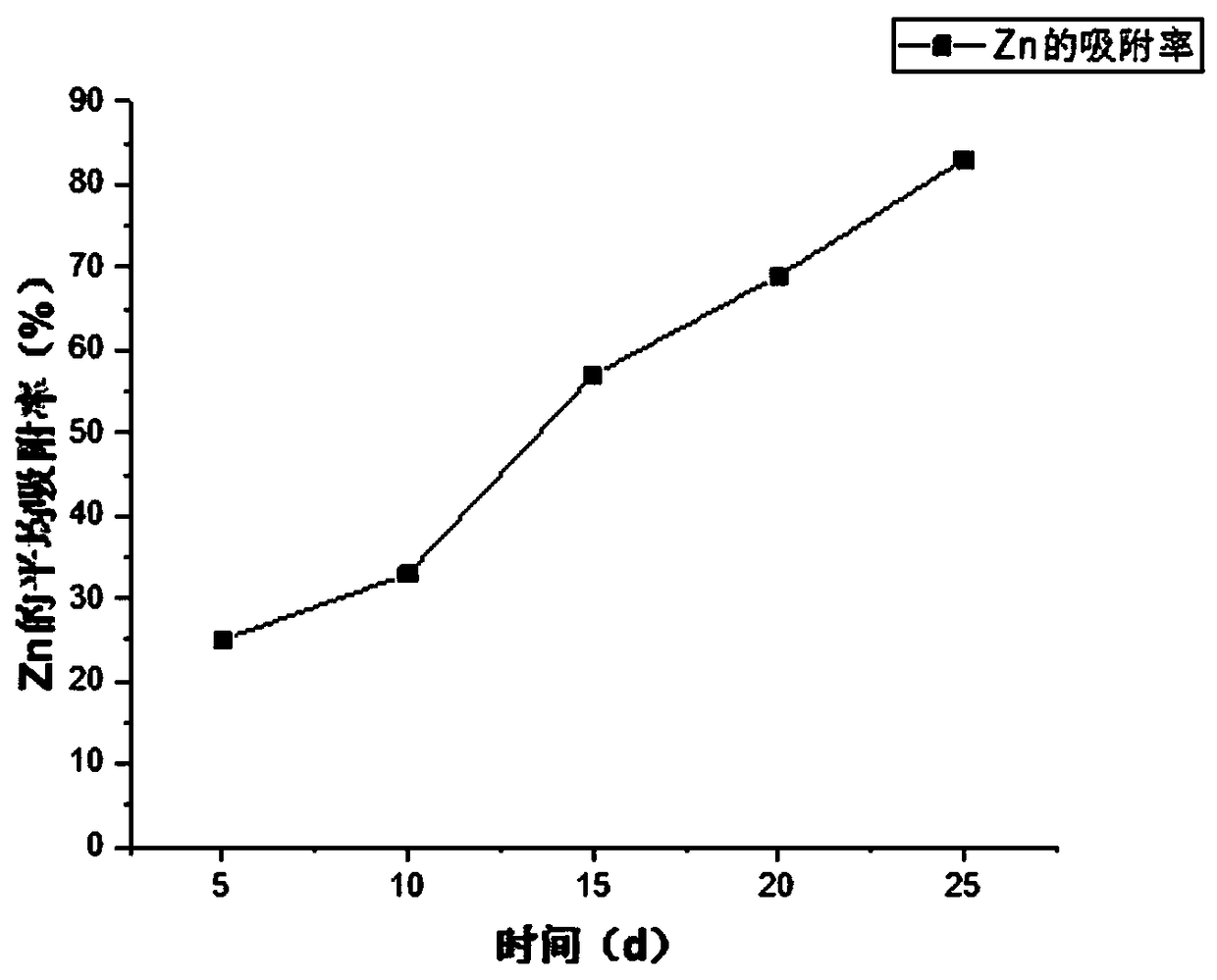

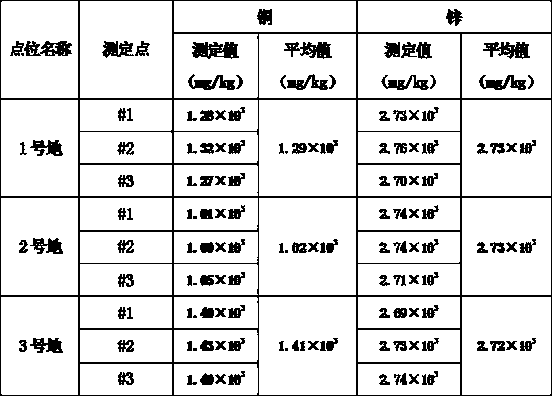

[0027] Taking the land where the production workshop of a copper smelting plant in Tieling City is located as the pre-repair area, three plots are selected as test plots, and three points are selected for each plot for determination. The soil test results before treatment are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com