Preparation method of theaflavins-rich black tea

A technology of theaflavins in black tea and theaflavins, which is applied in tea treatment before extraction, etc., can solve the problems of low theaflavins content, difficulty in increasing theaflavins in black tea, and high extraction cost, and achieve high nutritional value and effective Good for accumulation, high content of theaflavins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of high theaflavin black tea of the present invention comprises the following steps:

[0024] (1) Picking leaves: select one bud, two leaves and three leaves of the detached fresh tea leaves picked from the tea tree on the same day as raw materials.

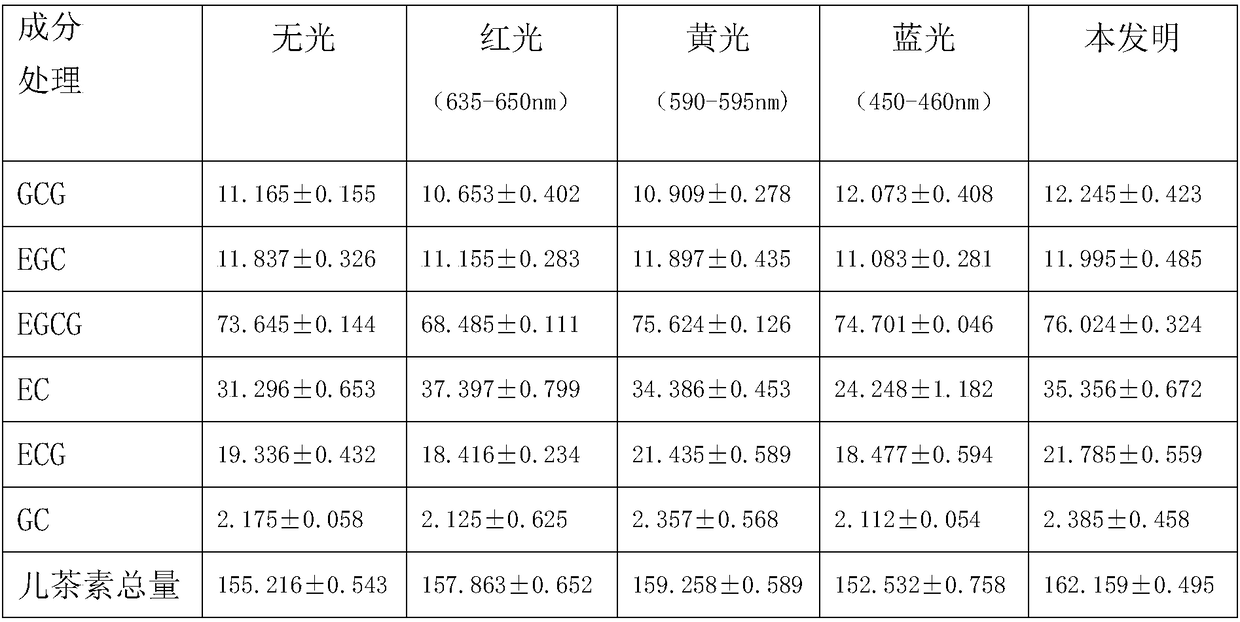

[0025] (2) Withering: Spread the picked raw materials evenly on the leaf curtain of the withering trough, spread 4-6 kg of leaves per square meter, and the thickness of the spread leaves is 18-20 cm, and carry out natural wind blowing withering. Light~blue light~yellow light are irradiated alternately, the wavelength of red light is 635~650nm; the wavelength of blue light is 450~460nm; the wavelength of yellow light is 595~600nm; The total time of light-changing withering is 6-8 hours, and the light intensity is 2100-2500 lux. After the light compensation treatment, the traditional no-light compensation withering is carried out, and the total time is 2-3 hours; during the whole withering proc...

Embodiment 1

[0031] A kind of preparation method of high theaflavin black tea of the present invention comprises the following steps:

[0032] (1) Picking leaves: select one bud, two leaves and three leaves of the detached fresh tea leaves picked from the tea tree on the same day as raw materials.

[0033] (2) Withering: Spread the picked raw materials evenly on the leaf curtain of the withering trough, spread out 4kg of leaves per square meter, and the thickness of the spread leaves is 18-20cm. Blue light~yellow light is irradiated alternately, the wavelength of red light is 635~640nm; the wavelength of blue light is 450~453nm; the wavelength of yellow light is 595~596nm; The duration is 6 hours, and the light intensity is 2100-2200 lux. After the light compensation treatment, the traditional no-light compensation withering is carried out. Until the water content of the leaves is 70-72%, the withered leaves are obtained.

[0034] (3) Kneading: Put the withered leaves into the kneading m...

Embodiment 2

[0039] A kind of preparation method of high theaflavin black tea of the present invention comprises the following steps:

[0040] (1) Picking leaves: select one bud, two leaves and three leaves of the detached fresh tea leaves picked from the tea tree on the same day as raw materials.

[0041] (2) Withering: spread the picked raw materials evenly on the leaf curtain of the withering trough, spread the leaves 5kg per square meter, and the thickness of the spread leaves is 18-20cm, carry out natural wind blowing and wither, and use red light in turn during the withering process. Blue light~yellow light is irradiated alternately, the wavelength of red light is 640~645nm; the wavelength of blue light is 453~456nm; the wavelength of yellow light is 596~598nm; The duration is 7 hours, and the light intensity is 2200-2350 lux. After the light compensation treatment, the traditional no-light compensation withering is carried out, and the total time is 2.5 hours. During the whole wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com