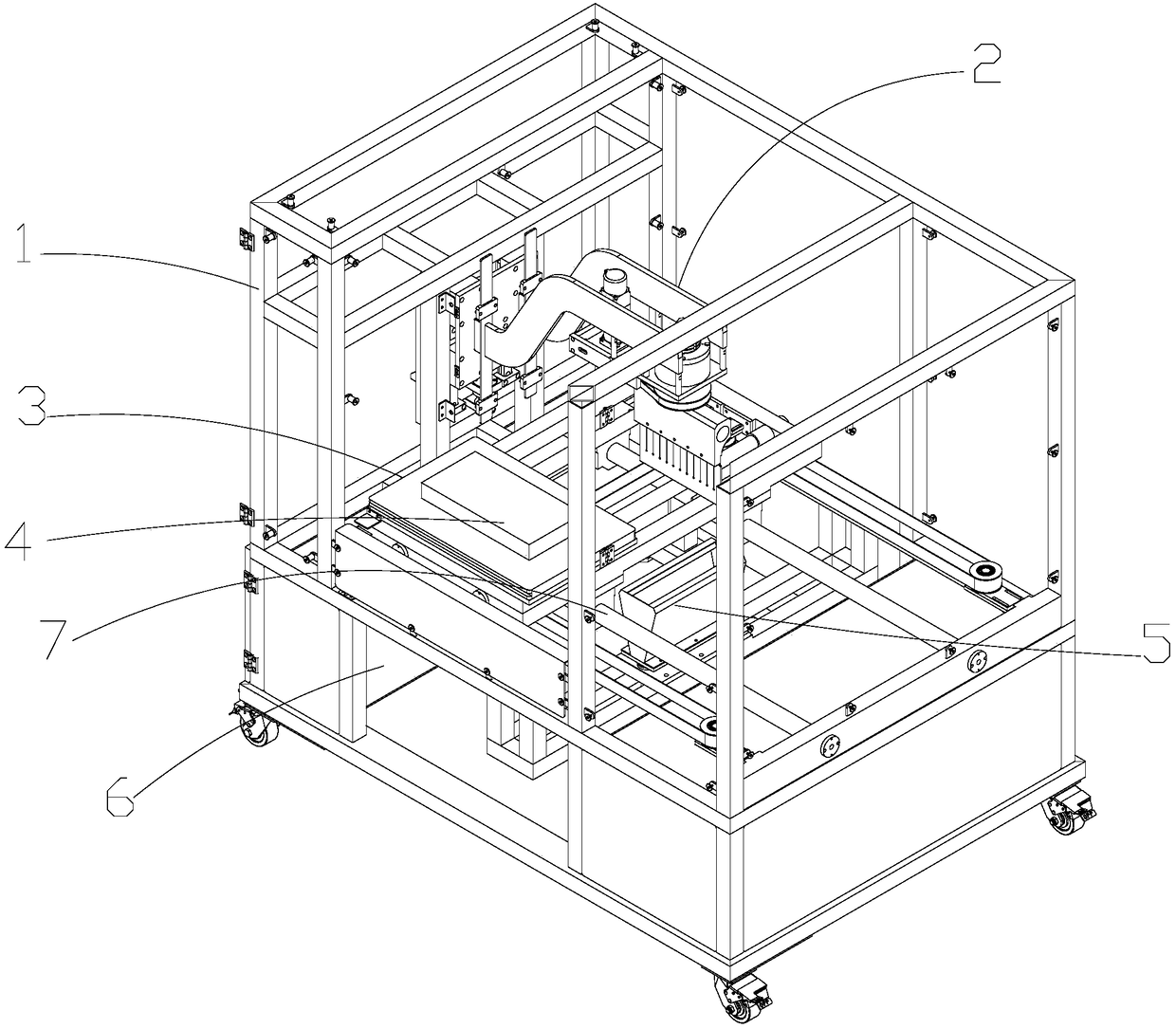

Ultrasonic cake cutting machine

An ultrasonic and cutting machine technology, which is applied in the field of cake preparation, can solve the problem of difficulty in ensuring the neatness and beauty of the cutting surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

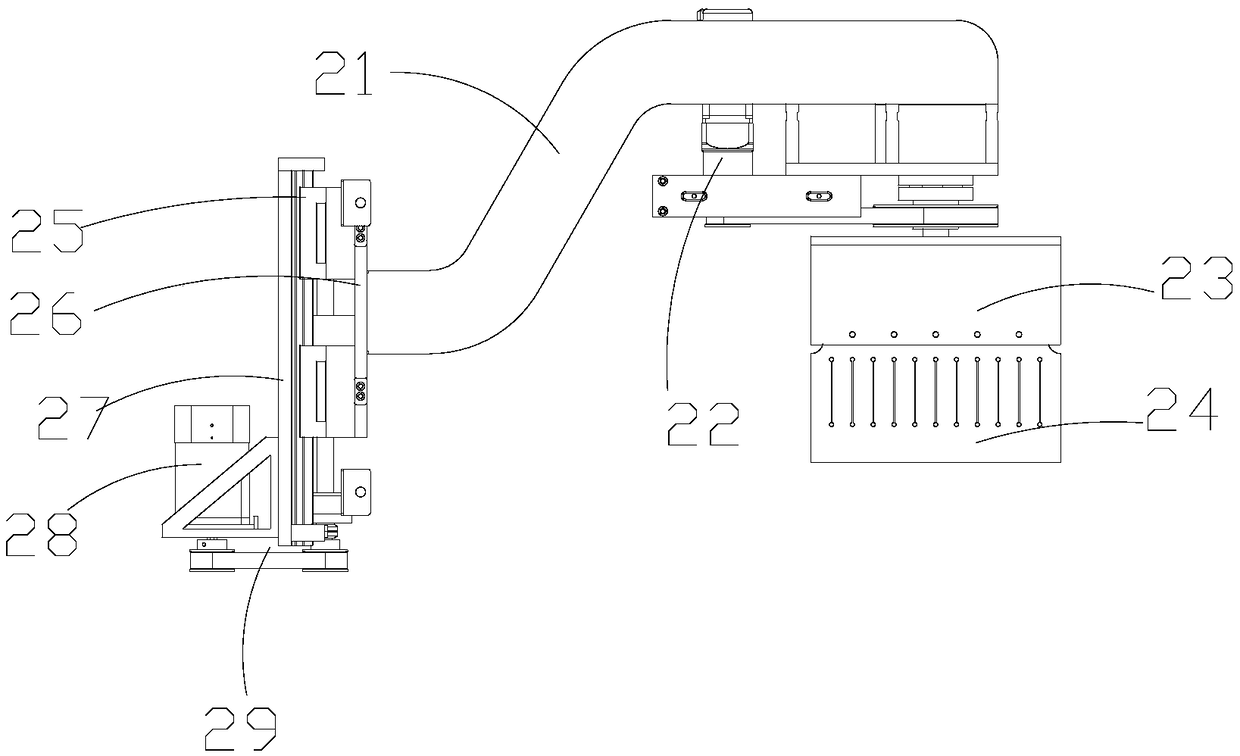

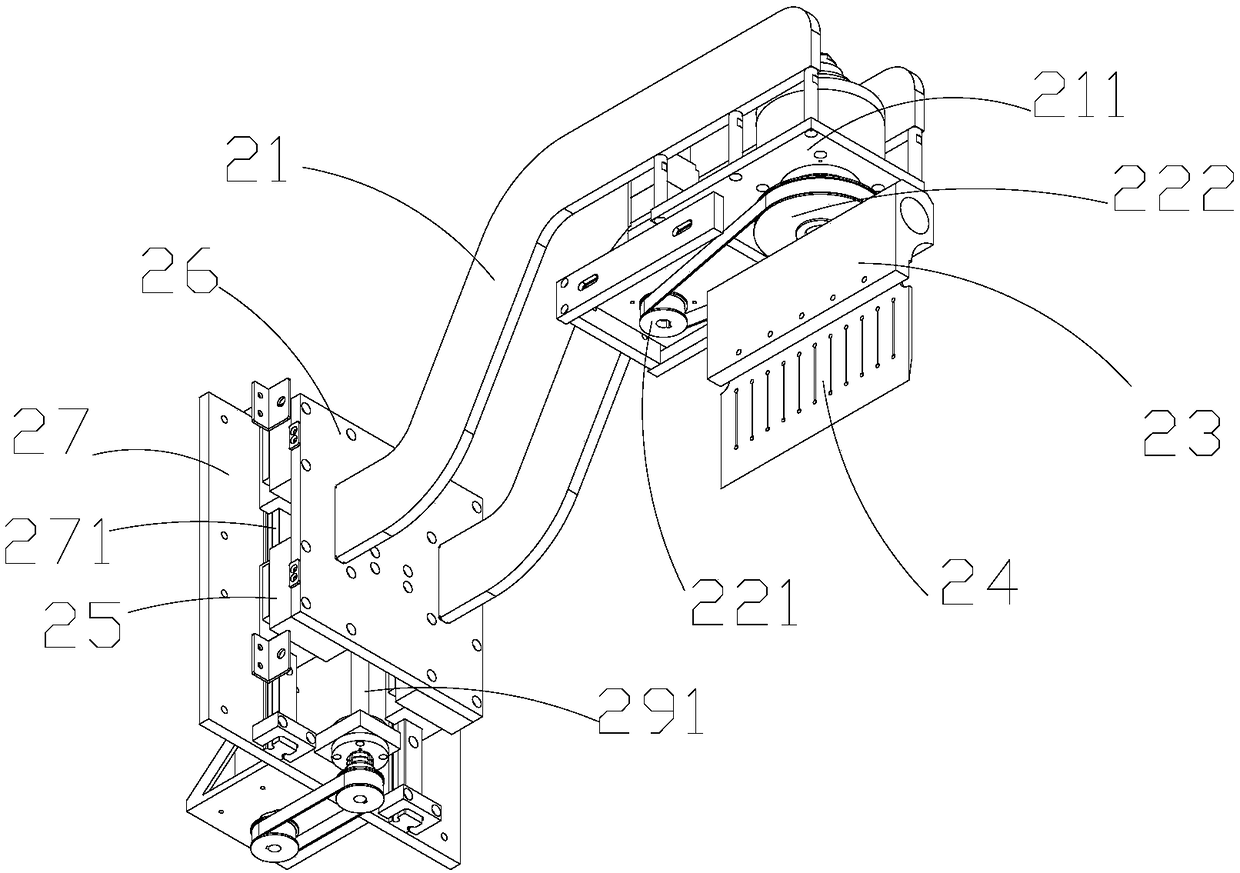

[0075] How cutting a square cake works:

[0076] Place the square cake on the operating table, and then the translation part of the operating table starts to work, pushing the cake forward to the bottom of the cutting part, and then the ultrasonic generator starts to work, sending ultrasonic waves to the cutting knife part, and the cutting knife part starts to move down Cut the cake until the square cake is cut off, then the cutting knife part moves upwards, and after leaving the square cake, at the same time, the translation part of the operating platform starts to work again and moves forward for a corresponding distance, and the cutting knife part starts to move down again to cut the cake until the The square cake is cut, and the cycle goes on and on, and the cake is cut to the corresponding number of segments according to the user's requirements;

[0077] The cutting knife part moves upwards. After leaving the square cake, the cutting knife in the cutting knife part rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com