<14>C sample preparation system for both hydrogen method and zinc method

A sample preparation and 14C technology, applied in the field of 14C sample preparation system, can solve the problems of high price, low yield and complexity of equipment comparison, and achieve the effects of excellent chemical stability, low expansion coefficient and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

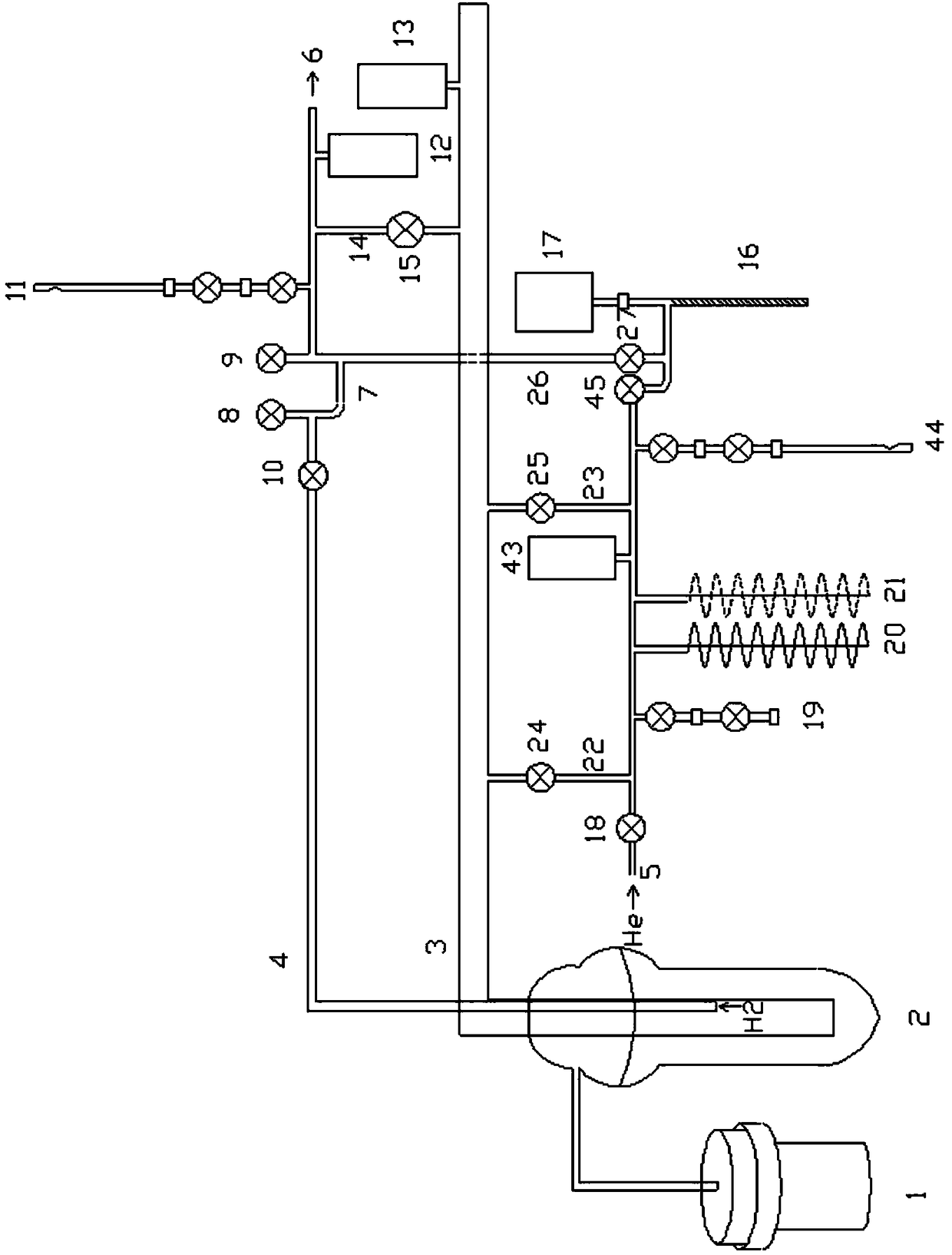

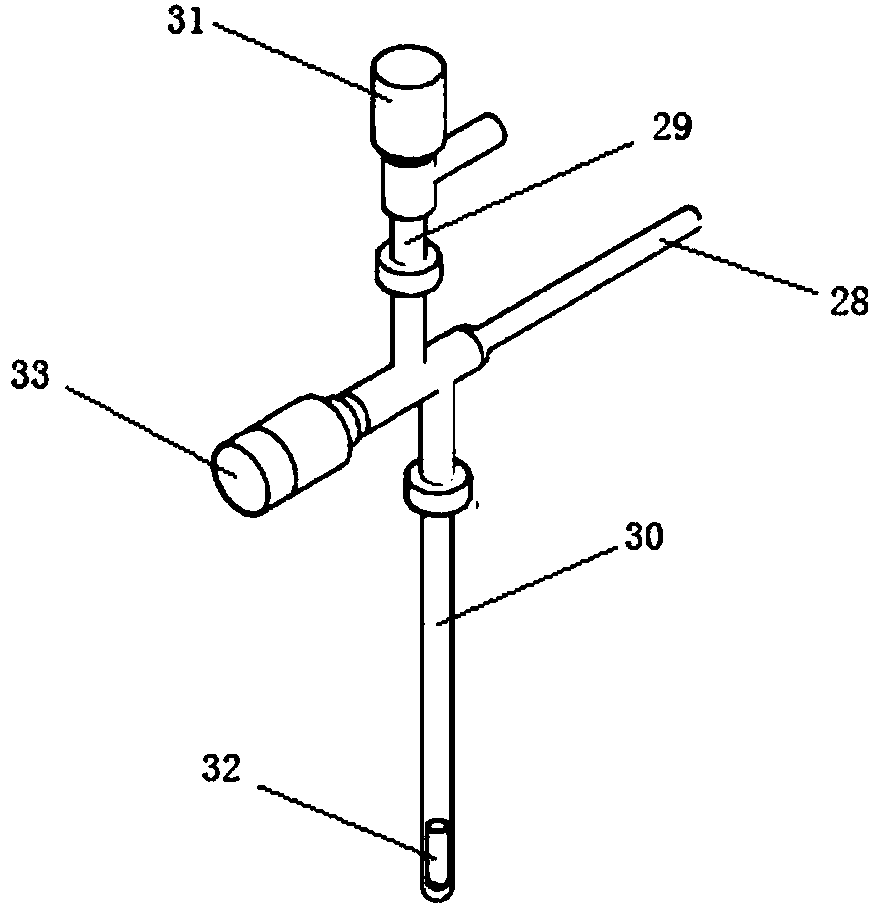

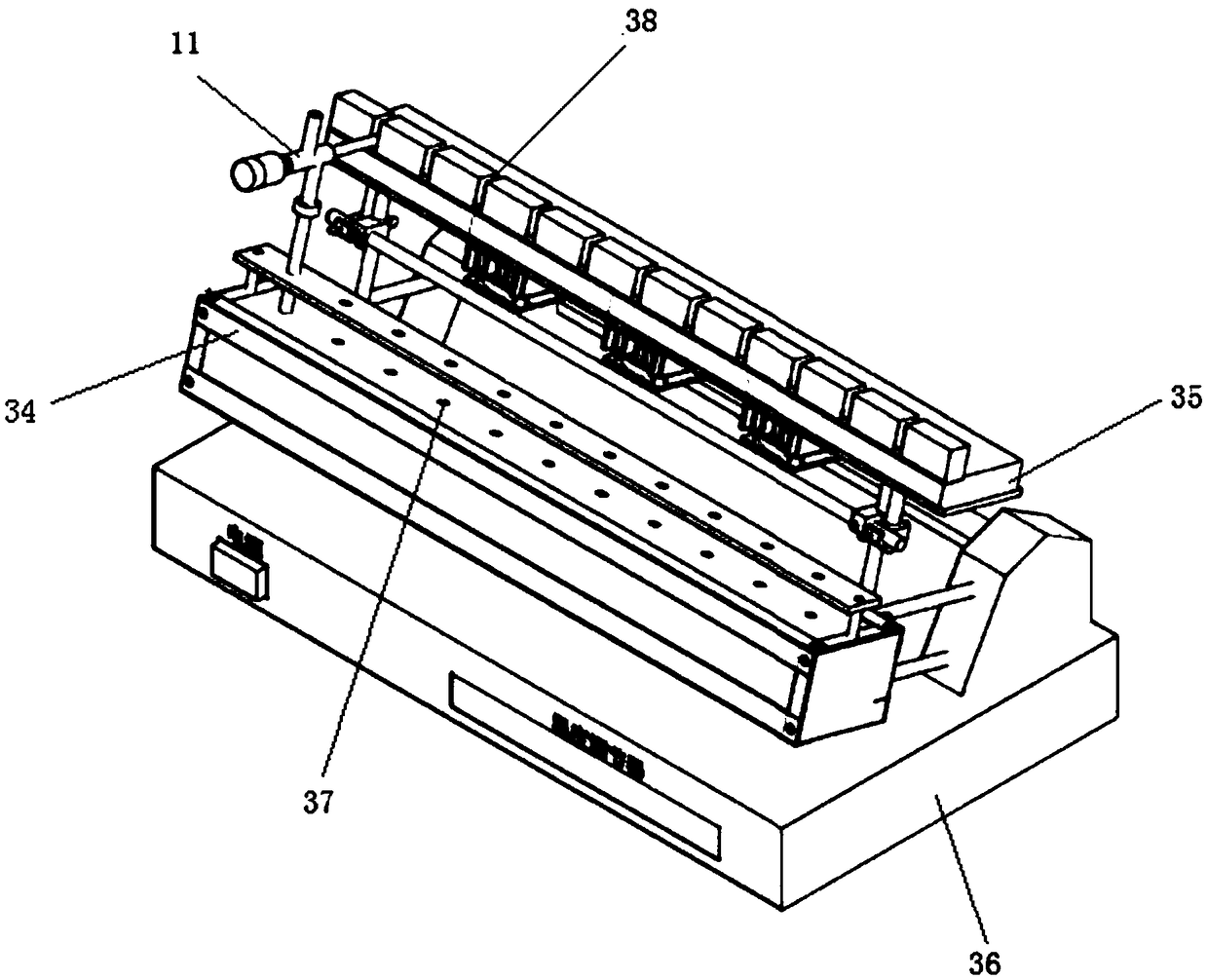

[0057] Such as figure 1 As shown, a dual-purpose hydrogen method and zinc method 14 C sample preparation system, including a vacuum pump 1, a liquid nitrogen cooling pump 2, a vacuum tube 3, a first quartz tube 4 and a second quartz tube 5. The vacuum pump 1 and the liquid nitrogen cooling pump 2 communicate with each other through pipelines. One end of the first quartz tube 4 communicates with the liquid nitrogen cooling pump 2, and the other end extends and communicates with the outside of the liquid nitrogen cooling pump 2 to form an exhaust port 6, and in the middle of the first quartz tube 4 A U-shaped pipe 7 is formed, and the two ends of the U-shaped pipe 7 are provided with a first valve 8 and a second val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com