A protective armor structure and design method in an explosion vessel

An explosion container and design method technology, applied in the structure of armor plate, protective equipment, armor, etc., can solve the problems of suboptimal anti-penetration performance, inconvenient replacement, easy to hurt people, etc., to achieve good anti-bullet effect, convenient Replacement, high protection factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

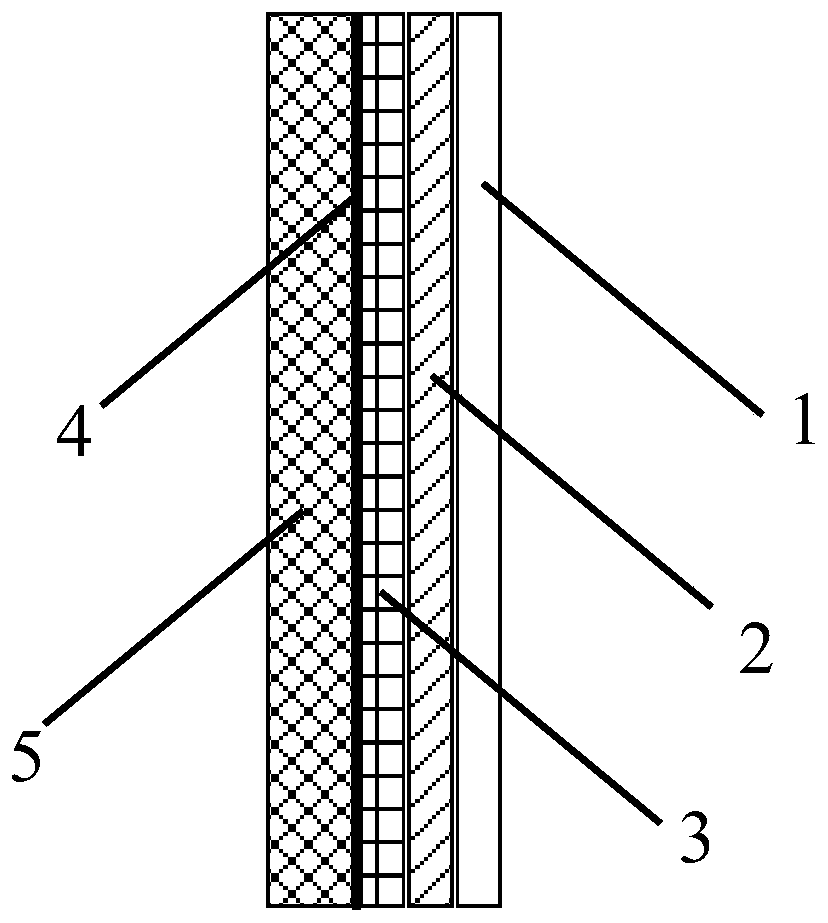

[0026] as attached figure 1 As shown, the protective armor structure in the explosion vessel is composed of deformed magnesium alloy 2, aluminum oxide ceramic 3, anti-explosion coating 4 and aluminum foam 5. The inner armor structure is closely attached to the main load-bearing layer of the explosion vessel through beading.

[0027] The design method of the protective armor structure in the explosion vessel, first fix the deformed magnesium alloy 2 with a thickness of 2 cm on the inner side of the main load-bearing layer 1 of the explosion vessel, and then bond the aluminum oxide ceramic 3 to the deformed magnesium alloy 2 with epoxy resin On the bullet-resisting surface of the alumina ceramic 2, a 2 mm thick LINE-X anti-knock coating 4 is sprayed, and a layer of 5 cm thick aluminum foam 5 is placed outside the anti-knock coating 4 .

[0028]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com