High-efficiency and environment-friendly steel strip degreasing agent and preparation and using method thereof

A degreasing agent and steel strip technology, applied in the field of metal surface chemical treatment, can solve the problems of poor anti-corrosion performance, low degreasing efficiency, high investment cost, etc., and achieve the effect of long service life, strong degreasing ability and high product concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

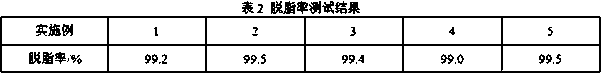

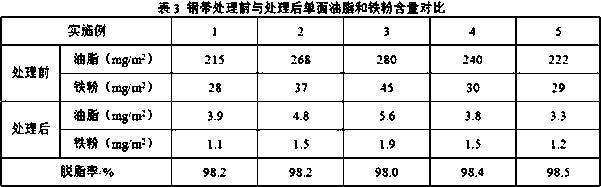

Examples

Embodiment 1

[0021] Preparation:

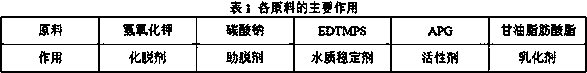

[0022] Mix 20 parts of potassium hydroxide and 10 parts of sodium carbonate, add 65 parts of water, stir at 40°C for 3 minutes, maintain the temperature and add 3.5 parts of EDTMPS, 5 parts of APG and 1 part of glycerin fatty acid ester to complete the solution.

[0023] Instructions:

[0024] Quantitative titration of the high-efficiency and environmental-friendly steel strip degreasing agent into the circulating fluid tank equipped with desalinated water, diluting it into an alkali solution with an alkali concentration of 2.8%, and quantitatively adding the high-efficiency and environmental protection steel strip degreasing agent to ensure that during the degreasing process The alkali concentration of the circulating liquid water tank remains unchanged, the steel strip passes through the circulating liquid water tank continuously, the temperature of the degreasing liquid is 50°C, and the passing speed of the steel strip is 320m / min.

Embodiment 2

[0026] Preparation:

[0027] Mix 25 parts of potassium hydroxide and 8.2 parts of sodium carbonate, add 61 parts of water, stir at 50°C for 3 minutes, maintain the temperature and add 4 parts of EDTMPS, 4 parts of APG and 0.4 parts of glycerin fatty acid ester to complete the solution.

[0028] Instructions:

[0029] Quantitative titration of the high-efficiency environmental protection steel belt degreasing agent into the circulating fluid water tank equipped with desalinated water, diluting it into an alkali solution with an alkali concentration of 2.5%, and quantitatively adding the high-efficiency environmental protection steel belt degreasing agent to ensure that during the degreasing process The alkali concentration of the circulating liquid water tank remains unchanged, the steel strip passes through the circulating liquid water tank continuously, the temperature of the degreasing liquid is 65°C, and the passing speed of the steel strip is 240m / min.

Embodiment 3

[0031] Preparation:

[0032] Mix 29 parts of potassium hydroxide and 4.8 parts of sodium carbonate, add 58 parts of water, stir at 60°C for 3 minutes, maintain the temperature and add 3 parts of EDTMPS, 3 parts of APG and 0.6 parts of glycerin fatty acid ester to complete the solution.

[0033] Instructions:

[0034] Quantitative titration of the high-efficiency and environmental-friendly steel belt degreasing agent into the circulating fluid tank equipped with desalinated water, diluting it into an alkali solution with an alkali concentration of 3.5%, and quantitatively adding the high-efficiency and environmental protection steel belt degreasing agent to ensure that during the degreasing process The alkali concentration of the circulating liquid water tank remains unchanged, the steel strip passes through the circulating liquid water tank continuously, the temperature of the degreasing liquid is 70°C, and the passing speed of the steel strip is 400m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com