Device and method for recovering tin of circuit board

A circuit board and tin stripping technology, applied in the improvement of process efficiency, photography process, instruments, etc., can solve problems such as secondary pollution, achieve the effect of realizing recycling, compact and reasonable equipment layout, and preventing copper layer from being corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Configure the original tin stripping solution: the components and their parts by weight are: 100 parts of methanesulfonic acid, 100 parts of tin methanesulfonate, 5 parts of comprehensive agent, 5 parts of copper protecting agent, and 200 parts of deionized water , mix the above components evenly to get the original tin stripping solution;

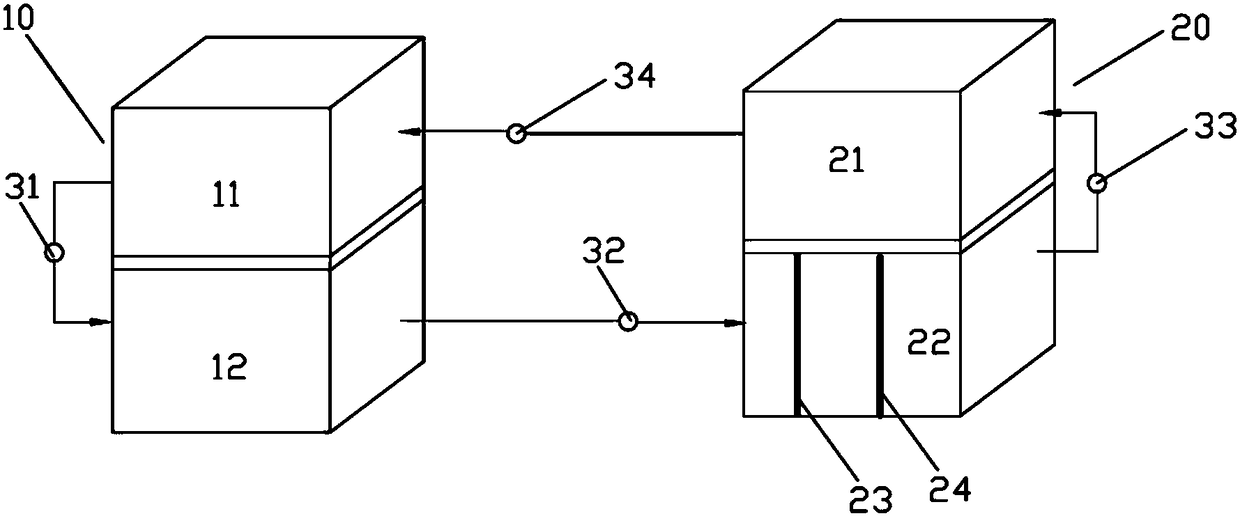

[0037] Step 2: Add the original tin stripping solution into the tin stripping tank 11, immerse the cleaned circuit board in the tin stripping solution in the tin stripping tank, and control the temperature of the tin stripping solution at 20°C by using a cooling or heating system Strip tin for 1 hour, and circulate the tin stripping liquid in the tin stripping tank through the circulation pump to ensure the uniformity of the tin stripping liquid in the tin stripping tank;

[0038] Step 3: measure the concentration of tin in the tin stripping liquid in the tin stripping tank, and when the concentration of tin reaches 120g / L, ...

Embodiment 2

[0042] Embodiment 2: the difference with embodiment 1 is as follows:

[0043] Step 1: Configure the original tin stripping solution: each component and its parts by weight are: 135 parts of methanesulfonic acid, 130 parts of tin methanesulfonate, 20 parts of comprehensive agent, 10 parts of copper protecting agent, 300 parts of deionized water , mix the above components evenly to get the original tin stripping solution;

[0044] Step 2: Add the original tin stripping solution into the tin stripping tank 11, immerse the cleaned circuit board in the tin stripping solution in the tin stripping tank, and use a cooling or heating system to control the temperature of the tin stripping solution at 30°C Strip the tin for 2 hours, and circulate the tin stripping liquid in the tin stripping tank through the circulation pump to ensure the uniformity of the tin stripping liquid in the tin stripping tank.

Embodiment 3

[0045] Embodiment 3: the difference with embodiment 1 is as follows:

[0046] Step 1: Configure the original tin stripping solution: the components and their parts by weight are: 170 parts of methanesulfonic acid, 170 parts of tin methanesulfonate, 50 parts of comprehensive agent, 8 parts of copper protecting agent, and 350 parts of deionized water , mix the above components evenly to get the original tin stripping solution;

[0047] Step 2: Add the original tin stripping solution into the tin stripping tank 11, immerse the cleaned circuit board in the tin stripping solution in the tin stripping tank, and use a cooling or heating system to control the temperature of the tin stripping solution at 30°C Strip the tin for 4.5 hours, and circulate the tin stripping liquid in the tin stripping tank through the circulating pump to ensure the uniformity of the tin stripping liquid in the tin stripping tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com