Spheroidizing and inoculating process for spheroidal graphite cast iron

A technology of nodular cast iron and spheroidization, which is applied in the field of spheroidization and inoculation technology of nodular cast iron, can solve the problems of increased burning loss of nodularizers, nodularization decline, casting scrapping, etc., and achieve the effect of improving the nodularization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

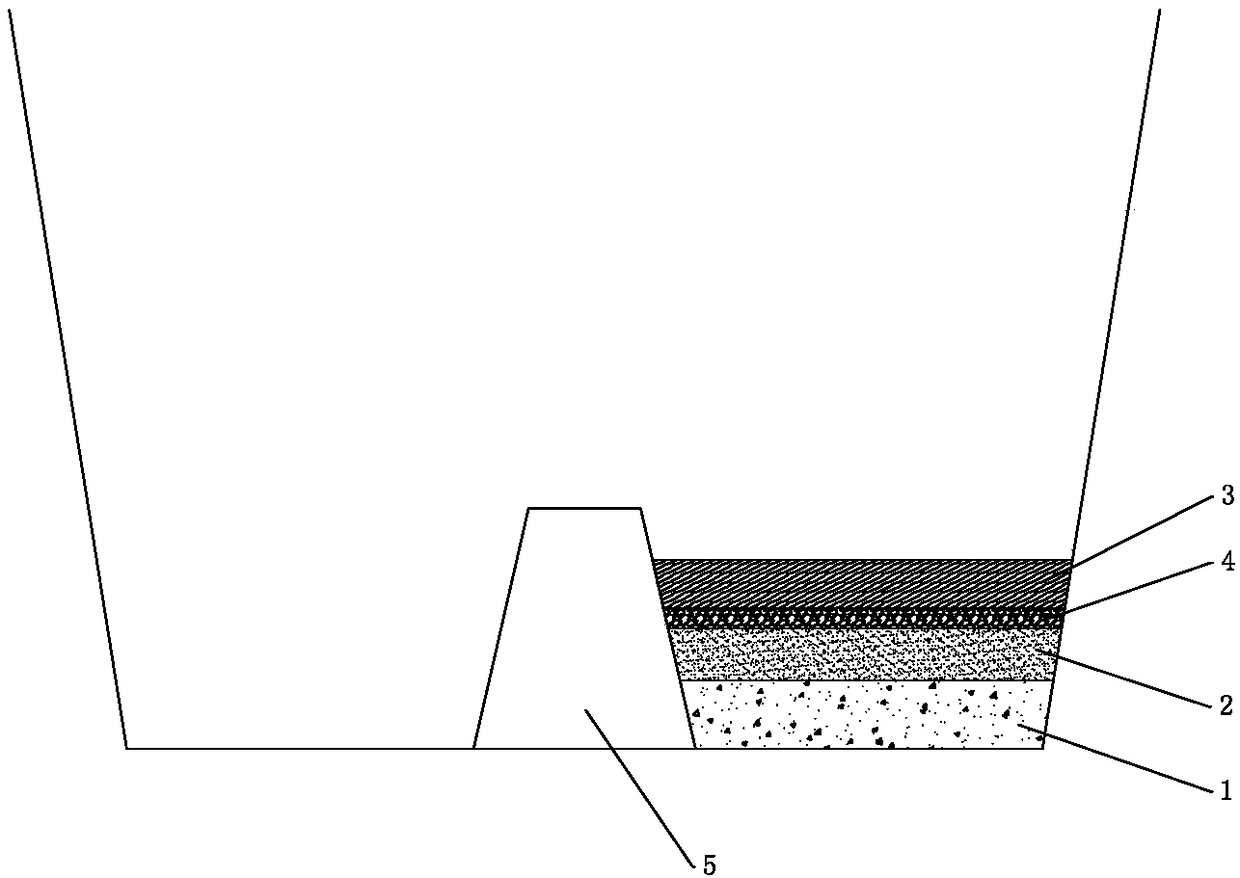

[0026] Such as figure 1 The nodularization and inoculation process of a kind of nodular cast iron shown comprises the following steps:

[0027] a. Material preparation: determine the total amount of nodulizer and inoculant required according to the total amount of molten iron, and dry the nodulizer and inoculant;

[0028] b. Alloy package: spheroidizing agent 1, part of the inoculant 2, and covering agent 3 are loaded into the package in sequence;

[0029] c. Spheroidization treatment: Pour part of the molten iron into the ladle quickly. The content of the molten iron poured into the ladle for the first time is two thirds of the total amount of molten iron. At this time, the molten iron can have the best spheroidization reaction effect, and the spheroidization reaction Near the end, add the remaining inoculant and the remaining molten iron;

[0030] d. Completion of treatment: After the spheroidization treatment, the slag is removed, and the slag is added to incubate with fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com