Adhesive sheet, display body and manufacturing method therefor

A display body and adhesive sheet technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of light reflection loss, etc., and achieve excellent effects of step difference followability and anti-foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0150] As another production example of the adhesive sheet 1 using the adhesive composition P, the coating liquid of the above-mentioned adhesive composition P is applied to the release surface of one release sheet 12a, and heat treatment is performed to heat the adhesive composition P. Cross-linking forms a coating layer to obtain a release sheet 12a with a coating layer. In addition, on the peeling surface of the other peeling sheet 12b, the coating liquid of the above-mentioned adhesive composition P is coated, and heat treatment is performed to thermally crosslink the adhesive composition P to form a coating layer to obtain an attached coating layer. The release sheet 12b. Then, the peeling sheet 12a with a coating layer and the peeling sheet 12b with a coating layer are bonded so that both coating layers may contact each other. If a curing period is required, the curing period will pass. If the curing period is not required, the above-mentioned laminated coating layer wi...

Embodiment 1

[0199] 1. Preparation of (meth)acrylate copolymer

[0200] 65 parts by mass of 2-ethylhexyl acrylate, 15 parts by mass of isobornyl acrylate, 5 parts by mass of N-acryloylmorpholine, and 15 parts by mass of 2-hydroxyethyl acrylate were copolymerized to prepare (methyl ) acrylate copolymer (A). The molecular weight of this (meth)acrylate copolymer (A) was measured by the method mentioned later, and the weight average molecular weight (Mw) was 500,000.

[0201] 2. Preparation of Adhesive Composition

[0202] 100 parts by mass (value in terms of solid content; hereinafter the same) of the (meth)acrylate copolymer (A) obtained in the above step 1, 0.25 parts by mass of trihydroxy Methylpropane-modified toluene diisocyanate, 5.13 parts by mass of ε-caprolactone-modified tris(2-acryloyloxyethyl)isocyanurate as active energy ray-curable component (C), 7.5 parts by mass The polyrotaxane compound (D) (manufactured by Advanced Softmaterials, product number "SeRMSuper Polymer SH3400P"...

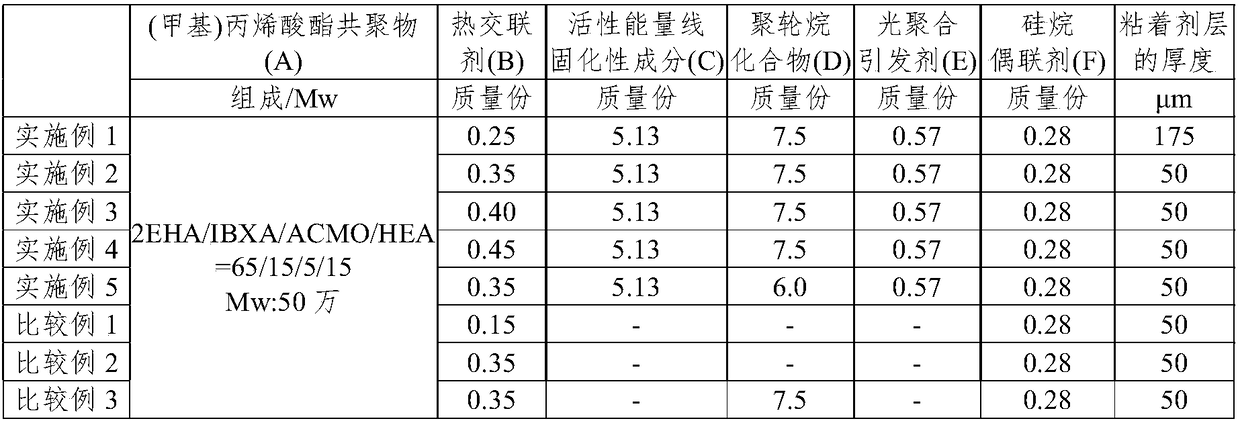

Embodiment 2~5、 comparative example 1~3

[0208] The mixing amount of thermal crosslinking agent (B), active energy ray-curable component (C), polyrotaxane compound (D) and photopolymerization initiator (E), and the thickness of the adhesive layer are shown in Table 1 Instead, the pressure-sensitive adhesive sheet was produced in the same manner as in Example 1 except that.

[0209] Here, the above-mentioned weight average molecular weight (Mw) is a weight average molecular weight in terms of standard polystyrene, measured under the following conditions (GPC measurement) using gel permeation chromatography (GPC).

[0210]

[0211] ■GPC measurement device: HLC-8020, manufactured by TOSOH

[0212] ■GPC column (passed in the following order): manufactured by TOSOH

[0213] TSK guard column HXL-H

[0214] TSK gel GMHXL (×2)

[0215] TSK gel G2000HXL

[0216]■Determination solvent: tetrahydrofuran

[0217] ■Measuring temperature: 40℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com