Bio-based waterborne paint and preparation method thereof

A water-based paint, bio-based technology, applied in the field of paint, can solve the problems of environmental and human damage, non-biodegradation of waste paint film, etc., to reduce environmental protection and reduce dependence on petroleum resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a kind of preparation method of above-mentioned bio-based water-based coating, comprises the steps:

[0025] (1) Weigh each raw material by weight percentage, 8-70% natural film-forming substance; 0-40% pigment; 0-65% filler; 8-40% modified wood powder; 0.2-1.0% Thickener; 0-2% drier; 0.1-0.4% defoamer; 0.1-0.25% wetting agent; 0.5-1.2% dispersant; 8-20% water;

[0026] (2) Add wetting agent, dispersant and defoamer in water in turn, stir at a speed of 3-5m / s, then slowly add pigments, and then disperse or sand-grind pigments and fillers at a speed of 20-25m / s Degree to less than 50μm;

[0027] (3) At a stirring speed of 6-10m / s, add water, filler, modified wood powder, defoamer, preservative and natural film-forming substance to the dispersion slurry obtained in step (2), and then add thickener and adjust the rotational viscosity of the slurry to 6×10 4 ~14×10 4 mPa·s, so as to obtain bio-based water-based coatings.

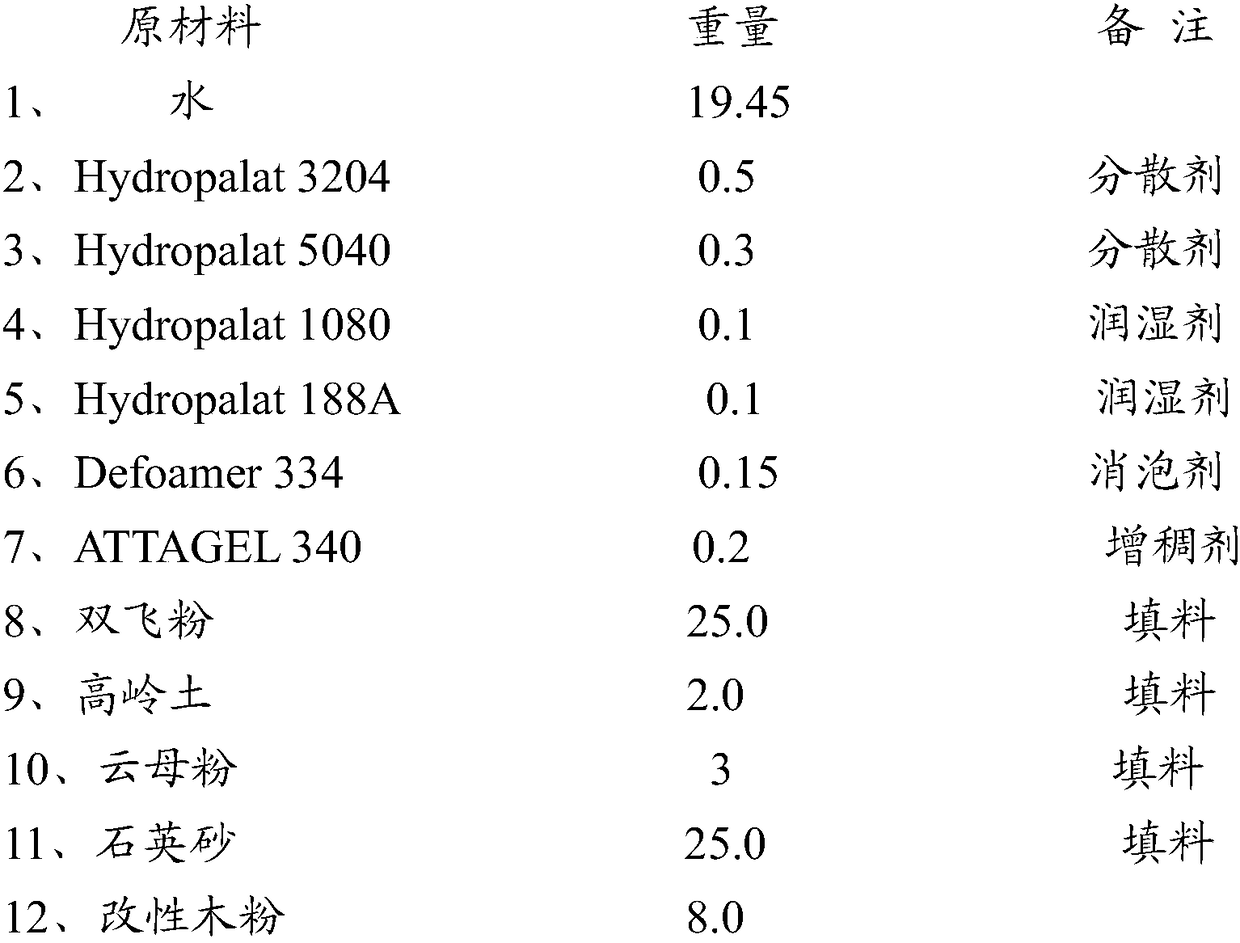

Embodiment 1

[0031]

[0032]

[0033] Add 1-10 components in an appropriate amount of water in turn, stir at a speed of 3-5m / s, then slowly add pigments, and then disperse or sand-mill the pigments and fillers at a speed of 20-25m / s to a fineness of less than 50μm;

[0034] At a stirring speed of 6-10m / s, add the remaining water and 11-14 components in sequence to the dispersion slurry obtained in step (2), then add 15-18 components and adjust the rotational viscosity of the slurry to 6× 10 4 ~14×10 4 mPa·s, so as to obtain bio-based water-based coatings.

[0035] The performance index of the bio-based water-based paint of gained is as shown in table 1:

[0036] Table 1

[0037]

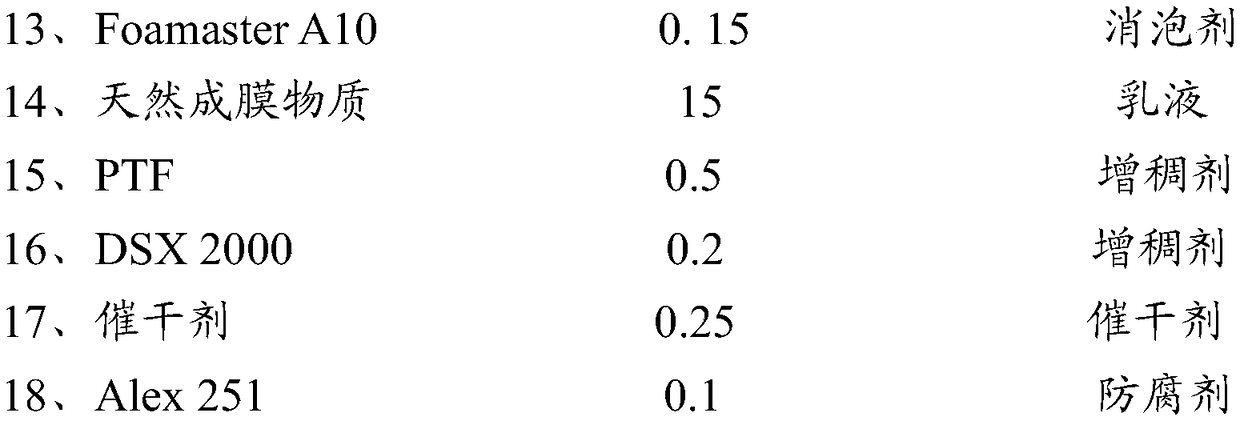

Embodiment 2

[0039]

[0040] Add 1-10 components in an appropriate amount of water in turn, stir at a speed of 3-5m / s, then slowly add pigments, and then disperse or sand-mill the pigments and fillers at a speed of 20-25m / s to a fineness of less than 50μm;

[0041] At a stirring speed of 6-10m / s, add the remaining water and 11-14 components in sequence to the dispersion slurry obtained in step (2), then add 15-18 components and adjust the rotational viscosity of the slurry to 6× 10 4 ~14×10 4 mPa·s, so as to obtain bio-based water-based coatings.

[0042] The performance index of the bio-based water-based coating of gained is as shown in table 2:

[0043] Table 2

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com