PCVD (plasma chemical vapor deposition) device

A deposition device and heating furnace technology, applied in the deposition device field of plasma chemical vapor deposition method, can solve the problems of increasing the cost of optical fiber, complex equipment structure, and the influence of the effective rod length of the preform, so as to reduce the standing wave intensity and improve the axis Uniformity and the effect of improving axial uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

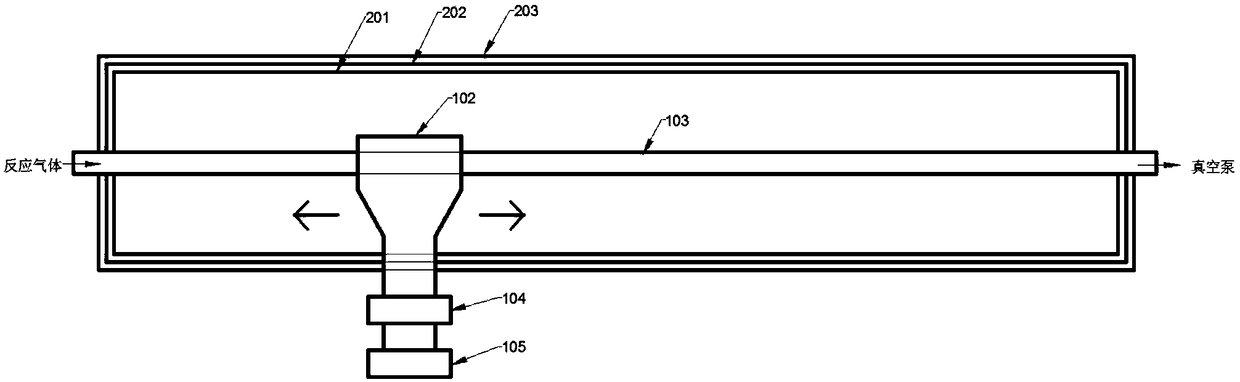

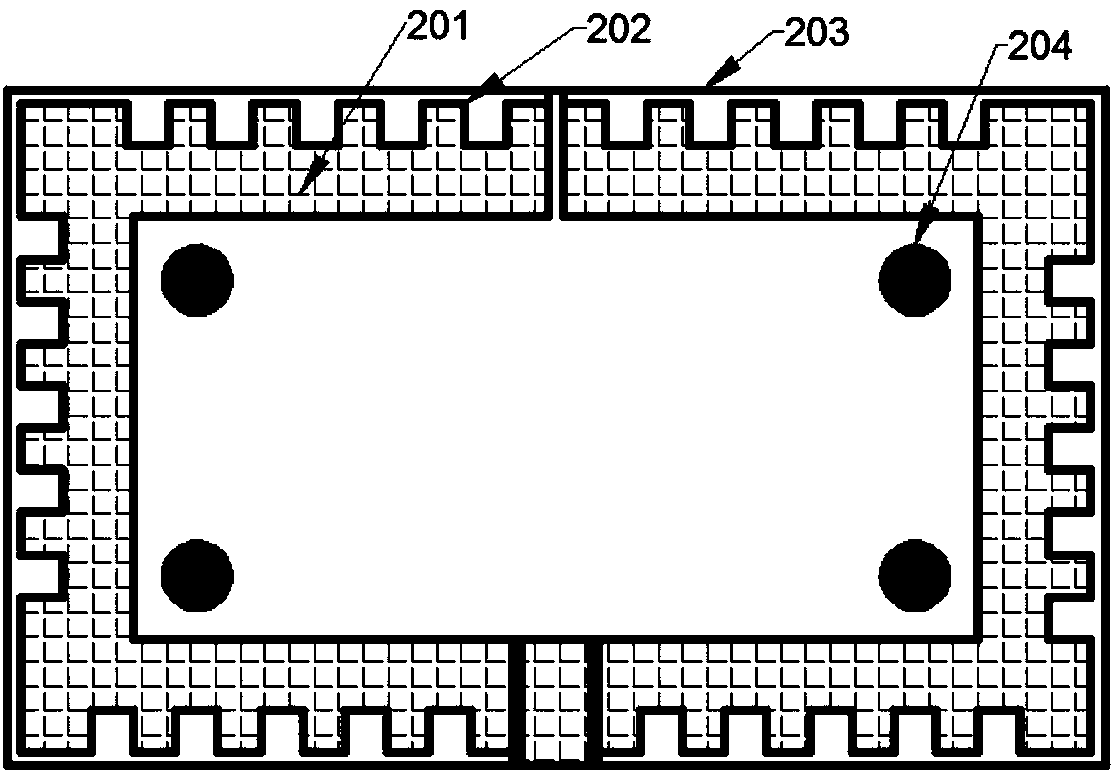

[0025] The first embodiment into figure 1 , 3 As shown, it includes a long cylindrical heating furnace and a resonant cavity 102 installed in the furnace cavity of the heating furnace. The long cylindrical heating furnace is composed of a furnace body that is opened and closed in half, and an open channel for the reciprocating operation of the resonant cavity is arranged in the middle of the lower end. The above-mentioned resonant cavity extends out of the heating furnace through the waveguide through the opening channel, and is connected with the axial reciprocating device and the microwave source 105, and is connected with the impedance matching unit 104. The glass liner 103 is installed along the axial direction of the heating furnace and passes through the resonant cavity. The reciprocating device drives the resonant cavity to reciprocate in the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com