Metal anchor filling technology and thermal detection device

A metal filling and anchor point technology, which is applied in metal material coating technology, semiconductor/solid-state device components, and technology for producing decorative surface effects, etc., can solve the problem of poor coverage of metal Al steps, poor coverage of Al steps, Problems such as poor filling ability of Al can achieve the effect of reducing contact resistance, reducing difficulty, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment proposes a metal anchor point filling technology and its improvement. In the process of manufacturing the uncooled infrared detector, it is necessary to manufacture the anchor point of the metal structure, which includes the following steps:

[0052] An anchor point is etched on an application specific integrated circuit (ASIC, Application Specific Integrated Circuit).

[0053] Electrode metal filled or sputtered by titanium aluminum (Ti or Ti / Al, Ti / TiN / AL) process.

[0054] In this process, the further improvement of traditional process methods requires metal W-CVD (tungsten-CVD) and W-CMP processes, and the introduction of expensive W-CVD machines and W-CMP, as well as the inevitable PI etching process. Since the anchor point has a certain area, with the reduction of the pixel size of the detector, if the existing titanium-aluminum process is used to fill, the side metal coverage will be relatively poor, the top metal will be thicker, the filling pro...

Embodiment 2

[0062] Embodiment two (describing the metal anchor point filling process):

[0063] In this embodiment, the improved process in Embodiment 1 will be further described in conjunction with the accompanying drawings:

[0064] In step one, an application specific integrated circuit (ASIC) with a planarized surface is prepared.

[0065] In a specific process, step 1 includes the following sub-steps:

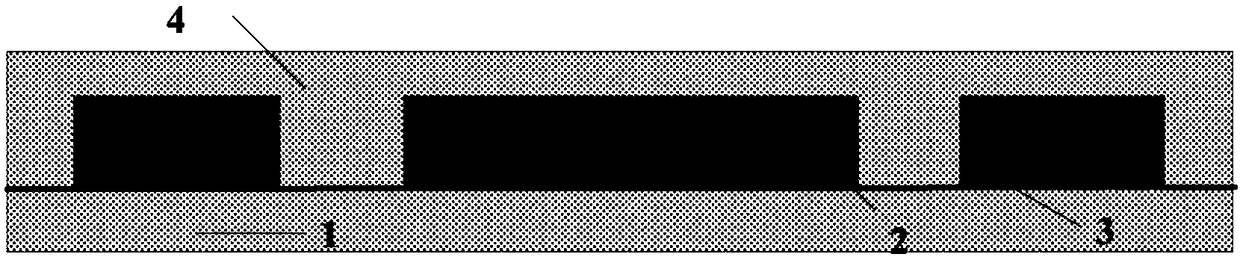

[0066] Such as figure 1 As shown, firstly, a TEOS layer, a Ti / TiN layer and a metal aluminum layer are sequentially deposited on the ASIC 1 .

[0067] Then, the reflective layer 2 and the circuit lead-out electrode 3 are obtained by using a standard photolithographic etching process.

[0068] Finally, a silicon dioxide or silicon nitride layer is deposited on the ASIC 1, the reflective layer 2 and the circuit lead-out electrode 3, and a planarization process is performed using a CMP process to form an ASIC with a planarized surface. ).

[0069] Preferably, the deposition thicknes...

Embodiment 3

[0082] Embodiment three (description product):

[0083] This embodiment will describe the product structure obtained by using the metal anchor point filling process in the previous embodiments, the structure includes:

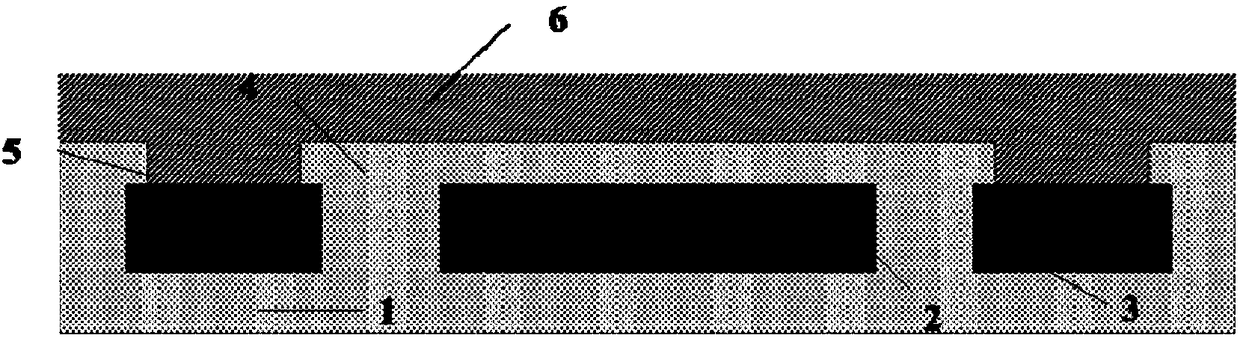

[0084] An ASIC 1 at the bottom, a reflective layer 2 and a circuit lead-out electrode 3 on the ASIC; covering the ASIC 1, the reflective layer 2 and the circuit lead-out electrode 3, and the carbon dioxide treated by CMP Silicon or silicon nitride layer 4 . Through the silicon dioxide or silicon nitride layer 4, the through hole 5 that is terminated at the circuit lead-out electrode 3; through the metal anchor point that fills the through-hole 5 and is patterned at the position corresponding to the circuit lead-out electrode 3 .

[0085] A sacrificial layer 7 is filled between the metal anchor points, and the sacrificial layer is flush with the top ends of the metal anchor points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com